Complex solutions like artificial intelligence are leading to electronic products becoming increasingly miniaturized and dense. To ensure components continue to meet benchmark standards, devices like microscopes, video magnifiers, automated optical instruments and more are used to visually inspect the electronic product.

Engineers working on product design or making lab adjustments to existing products need to understand basic supply chain concepts and issues such as end-of-life (EOL) and alternative parts.

but there are some standard best practices, including visual inspection and electrical testing.

1

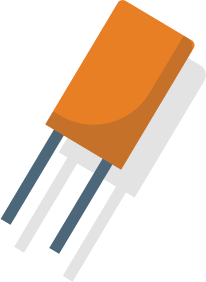

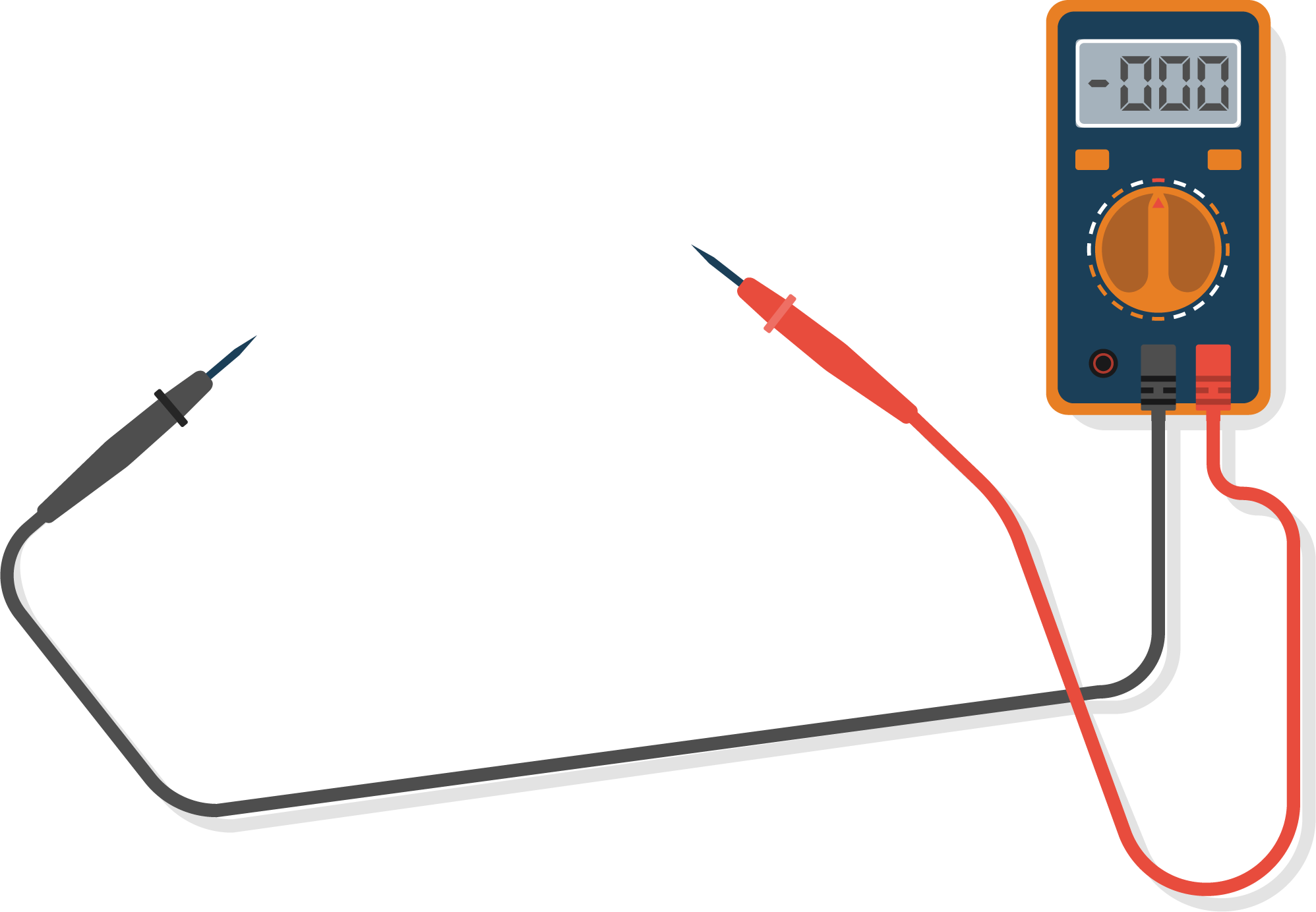

To guarantee that a component is working as it should, it is necessary to electrically test the component. Generally, basic values such as current and voltage are interconnected to measure and validate cable connectivity or component functions.

Arrow can help you optimize your BOM. Learn how.

1

Localized computing power

VISUAL INSPECTION

1

Localized computing power

ELECTRICAL TESTING

Testing electronic components can be a complex process,

READ ARTICLE

Learn more about the importance of component testing.

2

When it comes to sourcing components, it is important to consider international trade.

This includes reliability testing, durability testing and environmental stress screening.

Material sourcing is restricted or banned in some areas of the world. In other areas, it is banned which, in turn, can increase the cost of the product or require different versions for different markets.

Did you know? Arrow’s procurement services verify suppliers and components to ensure quality, origin and compliance, even when it’s necessary to use secondary market units.

Arrow can help you optimize your BOM. Learn how.

1

Localized computing power

RELIABILITY TESTING

There are several other individual tests that can take place throughout a product’s creation to ensure it is working properly.

1

Localized computing power

DURABILITY TESTING

1

Localized computing power

ENVIRONMENTAL

STRESS

SCREENING

This is used to determine weaknesses or faults in the manufacturing processes and process controls that could lead to a random failure. It can also be used to help determine the natural lifecycle of the product’s components.

Durability Testing helps find design weaknesses early in the product development cycle to help reduce costs and speed up time to market. It generally takes place after the first build and is conducted in an environment where it will be used.

This stage of testing reviews how components react to stresses related to temperature and vibration to reveal possible defects that could cause one aspect or the entire product to fail.

READ ARTICLE

Learn more about the importance of component testing.

3

Managing the supply chain is challenging during all stages of production, testing and delivering.

by eliminating the lost time, added expense and negative brand perception that inevitably comes with a failed product.

It is necessary to make sure sourced components are original (not counterfeit) and of good quality, especially if purchased secondhand.

Did you know? Arrow ships all purchases with full certificates of compliance, which remove the risk of counterfeit parts entering the supply chain.

Arrow can help you optimize your BOM. Learn how.

A well-thought-out test strategy can help deliver a clear return on investment

Most of the testing should be done during the design phase, with the goal being to get complete coverage because it’s more cost-effective in the long run of the product’s creation.

Consider automate testing and incorporate self-diagnostics. Not only should these solutions reveal if something isn’t working, but also why, to help inform your team how to fix it quickly.

READ ARTICLE

Learn more about the importance of component testing.