Automotive Friction Applications

Bostik’s Arofene™ product line is comprised of both phenolic resins and phenolic adhesives. With a long-standing history in the market for their reliability and supply security, these resins and adhesives are ideal for specialty, industrial applications that require high levels of durability even under extreme environmental conditions. They are used in the following ways:

Gain insight into how Arofene resins work well for your particular application.

Coated and Bonded Abrasive Applications

Adhesive Fortifier Applications

Aircraft Assembly Applications

Filtration Applications

Laminating and Pultrusion Applications

Arofene Rubber Modified Phenolic Adhesives (Arofene Adhesives)

Coated and Bonded Abrasive Applications

Adhesive Fortifier Applications

Aircraft Assembly Applications

Filtration Applications

Laminating and Pultrusion Applications

Arofene Rubber Modified Phenolic Adhesives (Arofene Adhesives)

Automotive Friction Applications

Arofene™ Phenolic Resins and Phenolic Adhesives

Improving Specialty Applications

Media saturants to provide heat, chemical and water resistance, alongside other, specialized properties, such as frictional coefficients

Prepreg resins to impart heat resistance

Adhesive fortifiers to improve adhesive formulations’ strength and heat resistance

Anti-corrosion primers to protect steel from corrosion and serve as am effective bonding surface for metal

Bonding adhesives for specialty and industrial applications that require high levels of durability even under extreme environmental conditions

Automotive Friction Applications

Arofene resins for the binder resin friction market have OEM approvals for their reliability and consistent performance and are specified for clutch rings and torque converters in both light vehicle and heavy-duty applications, such as tractor equipment. Able to be used as a saturant and an adhesive, they offer:

Arofene 295-E-50: Industry benchmark with excellent friction levels; for use in coating brake shoes and impregnation of paper applications

We recommend the following products:

Arofene 536-E-56: Heavy duty with excellent friction levels; for use in impregnation of papers for clutch plates and transmission band applications

Arofene 8678: Tung-oil formulation with high flexibility when cured; for modified coefficient of friction applications

Arofene 72155-W-55: Water based; low viscosity; binder for grain in coated abrasive applications

Arofene 8507-W-75: Water based; medium viscosity; color stable

Arofene 760: Water based; high solids; high viscosity; ultra-low formaldehyde (< 0.1%)

For Coated Abrasives

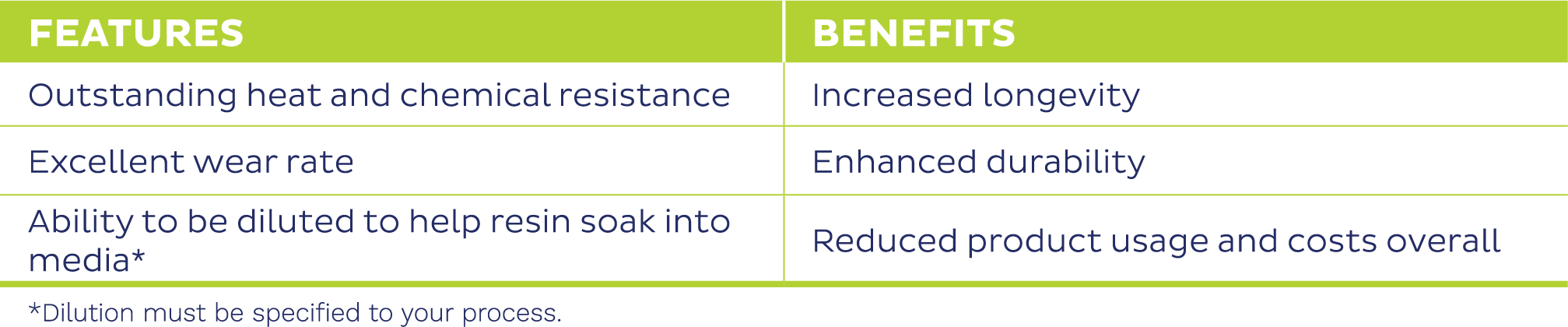

Arofene resins for coated (e.g. sand paper) and bonding abrasive (e.g. grinding wheel) applications are designed to withstand high heat environments, such as friction, and offer:

Coated and Bonded Abrasive Applications

We recommend the following products:

Arofene 8679-W-75: Water based; medium viscosity; designed for bonded abrasives

For BONDed Abrasives

Arofene 72155-W-55: Water based; low viscosity; self-emulsifying with good latex and PVA compatibility

Arofene 8454-W-55: Water based; low emissions; thermosetting; for latex adhesive formulations and fortification

We recommend the following products:

When used as an additive in wood-bonding or PVA adhesives, resins for these applications offer the following:

Adhesive Fortifier Applications

Arofene 101: Water based; low metals; meets Mil-R-9299C, Grade B; applications include clutch materials, insulating tape wrap for exhaust pipes and rocket motors as well as aircraft interior composites

Arofene 91LD: Medium viscosity; was the standard used to establish Mil-R-9299C, Grade B; designed for ablative applications requiring extremely low metal content; excellent temperature and corrosion resistance

We recommend the following products:

Specified for aerospace, commercial and military aircraft, Arofene resins are designed for interior and exterior, temperature-ablative applications, such as honeycomb structures, fuselage panels and prepregs. They also meet military specification 9299C and possess:

Aircraft Assembly Applications

Arofene 1106M: Water based; high viscosity; high solids; designed for laminating, molding and adhesive applications

Arofene 134A: Solvent based; superior ablative performance; has improved mechanical and physical properties; is dimensionally stable with heat resistance for structural laminates in nose cones, exit cones, ablative insulation, heat shields and filament winding

Arofene 2424M: Solvent based; recommended for use with glass, silica or quartz reinforcements; laminates made with Arofene 2424M exhibit excellent fire resistance; produces less smoke and is less prone to propagate fire than a conventional phenolic product; used in composite cabin interior applications

Arofene 8454-W-55: Water based with good latex compatibility; usually plasticized with PVA or acrylic latex

Arofene 8529 -W-55: Water based; good general purpose use

Arofene 8264 -ME-65: Used as the industry benchmark for performance and emissions; maintains flexibility

Arofene 8121-ME-65: Good performance and emissions; can be plasticized with PVA

Arofene 8095-W-50: Water based; self-emulsifying with good latex compatibility; usually plasticized with PVA or acrylic latex

We recommend the following products:

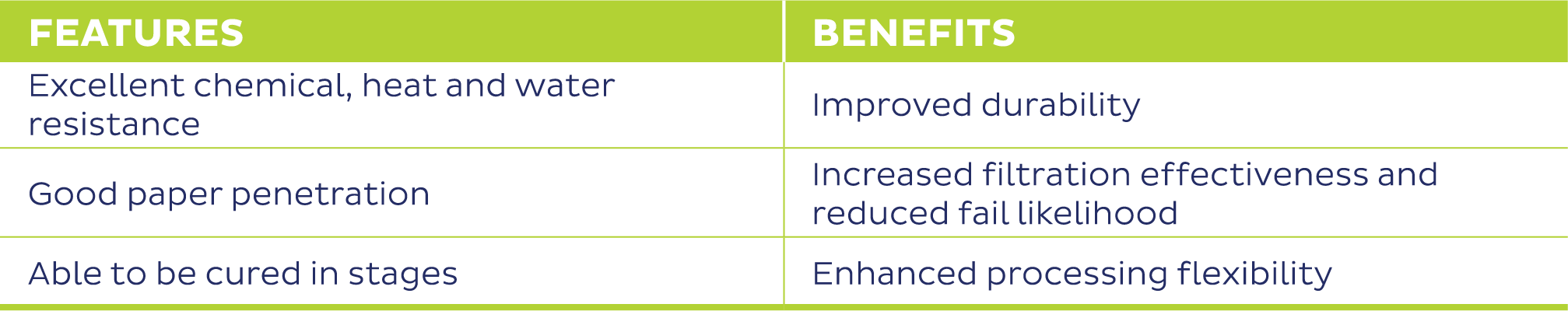

For air, fuel and oil filter assembly needs, these resins are water-based systems formulated with low phenol and formaldehyde and offer:

Filtration Applications

Arofene 8667-ME-70: Medium viscosity; in a methanol/water solvent; used for pultrusion, saturating, coating and laminating applications

Arofene 8383-E-56: Medium viscosity; modified; imparts exceptional ductility, impact resistance, heat resistance and flexibility

Arofene 8335-EA-60: Medium viscosity; in ethanol/acetone solvent; used in electrical and mechanical grade laminating applications

Arofene 4422-EA-59: Gum-rosin modified resin; medium viscosity; in ethanol/acetone solvent; used for high-performance electrical grade laminates and mechanical grade laminating applications; excellent flexibility, impact resistance and punching properties

We recommend the following products:

The first phenolic resins in the industry to pass Coast Guard approval for offshore oil rig gratings, these Arofene products enable proper processing for pultrusion especially, possessing:

Laminating and Pultrusion Applications

Arofene 72155-W-55: Water based; self-emulsifying with good latex and PVA compatibility; usually plasticized with PVA or acrylic latex

Arofene 1238: Low viscosity; dilutable; for friction bonding applications as a primer

Arofene 1240: Low viscosity; for friction or brake bonding applications as a primer

Arofene 1170: Low viscosity; corrosion resistant; for friction and gasket bonding applications as an adhesive, primer or coating

Arofene 1166: Medium viscosity; for friction and gasket bonding applications as an adhesive and coating

Arofene 1063B: High viscosity; extrudable; for drum brake applications as an adhesive

We recommend the following products:

Certain critical applications, such as brakes, transmissions and gaskets, require materials that offer extreme durability. To address those needs, our rubber-modified, phenolic Arofene adhesive formulations match the process and product requirements, offering:

Arofene Rubber Modified Phenolic Adhesives (Arofene Adhesives)

Arofene 1252: Medium viscosity; for friction and gasket bonding applications to metal

Arofene 1311: Low viscosity; non-blocking; low tack; for friction and gasket bonding applications

Arofene 1398: Low viscosity; PVB-modified; for friction and brake bonding applications as a primer

Arofene 1398 HV: Medium viscosity; high dilutable; PVB-modified; for bonding friction, clutch, disc brakes and metal primer applications

Arofene 1400: Low viscosity; PVB-modified; for friction bonding applications

Contact a Bostik expert today!

Ready to get started with our Arofene resins and adhesives?

©2023 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer