As demands for increased package end-use performance and reduced environmental impact rise across the flexible packaging industry, it’s critical for converters or film producers like you to understand the role the right adhesives play in your ability to address them.

However, at Bostik, we understand your equipment typically determines what capabilities you can provide for both food and non-food applications. Therefore, it’s a good idea to know how Bostik's cold seal, heat seal, reseal and laminating adhesive solutions can still help you meet those demands regardless of equipment.

Meet Flexible Packaging Demands

for Coating and Extruding Equipment

Cold Seal

Bostik's Coating Solutions

Designed for both paper and film packaging substrates, including OPP, PE, PET, paper, and compostable substrates

Coating Solutions

Increase production efficiencies and line speeds by:

Pro Tips for Optimizing Cold Seal Production Efficiencies

If You Have Coating Equipment...

The Right Solution for Your Equipment

Cold Seal

Heat Seal

Reseal

Laminating Adhesives

Reseal

Heat Seal

Our adhesive coatings can be used and interchanged on existing coating equipment. Click on our solutions to learn more:

If You Have Extruding Equipment...

Our extruded adhesive solutions are suitable for both cast or blown extrusion processes. Click on our solutions to learn about their values:

Our Turbo-Seal® water-based, cold seal adhesive coatings are:

This versatile performance capability helps broaden your package design capabilities. One cold seal can often be used across substrates, too. This allows for production efficiencies by reducing SKUs.

Our Turbo-Seal coatings are no foaming or streaking

This capability helps improve coating quality.

Combined with natural rubber latex (NRL) and proprietary synthetic polymers

Available in formulations for mono-web and laminate structures, our solutions provide balanced cohesion and adhesion for high-performance, consistent seal integrity.

Approved for How2Recycle® Store Drop-off labels

Their high-performance levels have enabled them to pass the Association for Plastic Recycler’s Critical Guidance testing for PE films and be approved for How2Recycle Store Drop-off labels. This capability allows you to reduce recycling stream impact in addition to meeting seal performance needs.

Removing all latex-based tubing from your cold seal adhesive station

Increasing the doctor blade angle

Adjusting the mixing speed of the holding tank

Cleaning the equipment of any dried cold seal

Cleaning while the press is running

If you’re looking to shift from laminating to surface print applications...

Consider:

Bostik’s cold seal adhesive coatings, as well as overprint varnishes, support the transition to a single ply structure, helping you reduce overall materials. Additionally, Bostik’s cold seals are compatible with both laminating and surface print applications, reducing SKU complexities.

Where Our Cold Seal Solutions are Used:

Laminated

Nutritional, confectionary, bakery, protective films, mailers, collecting cards

Surface Print

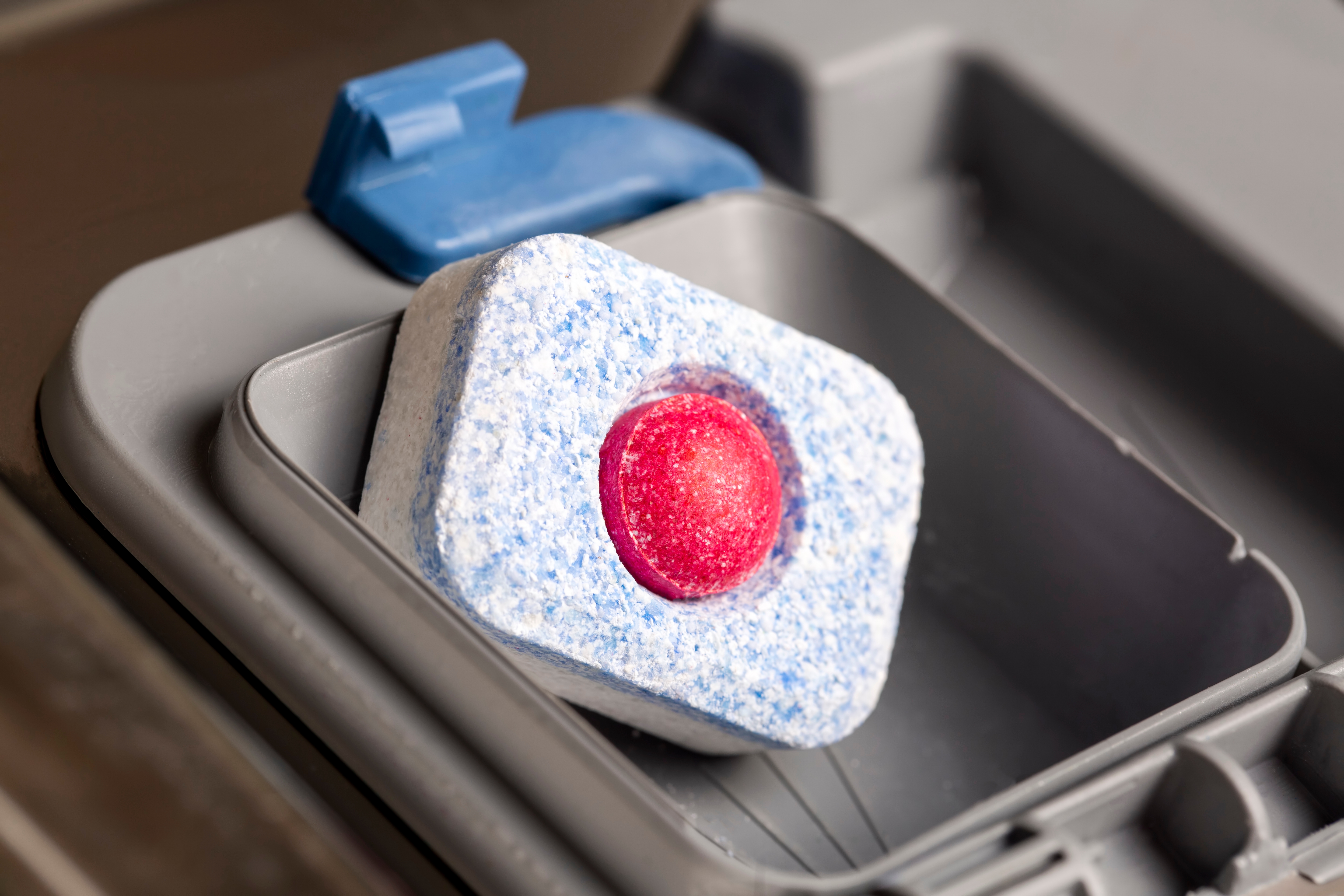

Miniature candy, frozen soft serve, protective films, sterilization packaging, dishwasher tablets, hotel toiletries

Overwrap

Individually wrapped candy, cheese slices, medical overwrap

Peelable or Lock Seal for Tray & Cup Lidding

Labels

Sterile Medical Devices

& Diognostic Test Kits Packaging

Where Our HEAt Seal Solutions are Used:

Heat seal adhesive coatings are capable of withstanding microwaving and steam sterilization.

If your packaging is protecting high-temperature products...

Consider:

While you can purchase film with heat seal coatings that film suppliers extruded, you can also custom formulate our coatings to better control the peel force via low coat weight and application pattern. This helps you achieve optimized performance needs.

Customized formulations

Our heat seal coatings can also offer anti-fog capabilities directly within their formulation. In addition to providing sufficient seal strength, they help mitigate water droplets from forming on the package lidding, which increases package transparency.

Anti-fog capabilities

Our heat seals protect packaging that contains products with high-acidity or chemical content, enabling packaging longevity and usage for sauce or condiment applications.

Chemical resistance

Our heat seal coatings can withstand high heat from microwaving and steam sterilization. This performance capability enables versatile application usage for food and medical applications as well as shrink labels.

High temperature resistance

Our water-based and solvent-based heat seal adhesive coatings offer:

HEAT Seal

While the specific dual functionalities can vary depending on your performance needs, our heat seal coatings allow your packaging to use about 30% less material compared to rigid claim shell packaging* as a result of offering two or more performance capabilities in one product.

Dual functionality

You can increase functionality in films with our heat seal adhesive coatings through gravure coating, flexographic printing and other techniques.

By adding about a 1mm x 10mm strip of heat seal coating to the inside, you can properly secure shrink labels in place to reduce waste potential and increase brand awareness.

Whether your heat seal package has a label...

Airbag & Automotive Sensor Packaging

Battery & Memory Card Packaging

Cosmetic & Toiletries Packaging

Labels

Die Cut Lidding

Where Our RESeal Solutions are Used:

Bostik’s reseal offers anti-blushing capabilities to allow a package to opened without altering the lid graphics.

If you’re packaging material with high-moisture content...

Consider:

Our reseal solutions offer customizable peel performance, such as �high or low peel. This helps you tailor the performance capability to �the end-use package application.

Able to be customized

Their high performance capabilities allow the packaged to be resealed package more than ten times* while keeping food fresh. This in turn helps reduce food waste and decrease plastic material usage by 30%* compared to clamshells.

Able to reduce environmental impact

Our solvent-based coatings offer transparency for high-moisture products without water whitening, which improves end-use package visibility.

Able to eliminate blushing

This allows you to achieve your desired peel strength.

Formulated for press-ready, coat weight customization

This performance capability allows you to expand your packaging options for food and non-food products.

Compatible with die cut package designs such as PET and Polyolefin

laminate structures

Our coater-ready, water-based and solvent-based coatings are:

RESEAL

Hatch or Partially Open Lidding

Our solutions received Plastic Sense Foundation certification for APET tray recycling, which means they do not contaminate the tray during the recycling stream.

Certified for APET tray recycling

Medical

Where Our laminating adhesives are Used:

Bostik’s laminating adhesives allow for dual functionality of film lamination and zipper lamination. They can run >1,300 feet per minute with no misting to keep production lines moving. Additionally, they have fast curing with slitting capabilities in as little as three hours to allow same day converting and slitting.

If you’re looking for ways to streamline...

Consider:

Our Recyclass-certified laminating adhesives have been proven to yield little to yield little to no impact on polyethylene recycling streams.

Recyclass-certification

Our laminating adhesives can be clear, which enable you to manufacture transparent package formats.

Transparency

Their crosslinking abilities help increase bond strength needed for demanding applications. You can also apply minimal coat weights and still achieve the necessary bond performance. This helps you reduce adhesive usage.

Good bond strength

This helps ensure your package can maintain performance even in harsh storage conditions.

High heat, chemical, product and weather resistance

This performance capability helps you increase design options for end-use package applications.

Versatile adhesion to substrates such as PET, PP, PE, foils and paper

Our solvent-free, water-based and solvent-based solutions offer:

Laminating Adhesives

Retort

Snack Foods

Coffee

Outdoor Consumer

Fertilizer, Soil

Pet Food

Confectionary

Fresh Produce

Utilizing a Bostik heat seal resin requires no drying during conversion to help increase line speeds.

If you’re trying to increase manufacturing efficiencies...

Consider:

This capability helps minimize excessive adhesive usage and reduces waste.

Consistent, preceise application

You can customize formulations with cast or blown extrusion to achieve desired performance results.

Ability to customize formulations

In addition to meeting performance requirements, this capability helps you keep production lines moving for increased throughput.

High bond strength

While the specific levels can vary depending on your performance needs, our heat seal coatings provide resistance for substances that may contain chemical, oil or vinegar coating goods. Our Bostik team will help you determine the correct line settings for your equipment to provide ease of processability.

Resistance levels for hard-to-hold substances

Our extruded heat seal adhesives offer:

Heat Seal

Airbag & Automotive Sensor Packaging

Battery & Memory Card Packaging

Cosmetic & Toiletries Packaging

Sterile Medical Devices

& Diognostic Test Kits Packaging

Labels

Peelable or Lock Seal for Tray & Cup Lidding

Where Our EXTRUDED HEAT SEAL SOLUTIONS are Used:

Where Our EXTRUDED RESEAL SOLUTIONS are Used:

Bostik’s extrudable reseal allows for flange sealing to the tray, meaning consumers have to quick access to products for ease of use.

Whether you want the consumer to have full access to the product in the package...

Consider:

Based on Recyclass and Ecosense testing, our m-resins enable you to use recycle the tray and its lidding via mechanical circular recycling.

Recyclass and Ecosense Foundation certification for PE films and trays

Certain extrudable hot melt grades have a shelf life of up to nine months to help ensure optimal processing windows.

Optimal processing windows

Our m-resins do not require laser scoring on cast and blown film lines. This performance capability allows you to seal resealable films at the same rate as traditional, single-peel films.

Ability to be processed on standard multi-layer extrusion equipment

Designed for flange seal lidding tray packaging, our m-resin adhesives were the market’s first patented extrudable hot melt reseal seal and are available in various formulations to meet specific requirements.

Various temperature and humidity ranges

Our m-resin reseal adhesives have:

RESeal

Razors, Medical, Tissue

& Personal Care

Produce, Confectionary, Meat & Cheese

Flange sealed, fully open lidding

As the adhesives solutions segment of Arkema, we are a key player in the cold seal, heat seal, reseal and laminating adhesive technology markets. We are vertically integrated to help customers around the globe with an expansive portfolio of coating and extrudable solutions.

What to Expect When Working with Bostik

Pre-qualification by How2Recycle® for Store Drop-off on PE film for Turbo-Seal® cold seal adhesives

Certification as recyclable on PE film by Recyclass for m-resin extrudable reseal

Certification as recyclable on PE trays by Ecosense Foundation for �m-resin extrudable reseal

Recyclass-certified laminating adhesives proven to show little to no impact on polyethylene recycling streams

Enhanced Sustainability: Our products have obtained key certifications to help ensure you are addressing recycling requirements, such as:

Technical Expertise: From on-site testing to troubleshooting, our team helps you find the right coater-ready or extrudable solution that will enhance your production efficiencies. We continually develop new formulations to help address unmet needs and offer pilot capabilities for proof-of-concept options before going into production.

Troubleshooting Support: We provide in-person support at our customers’ facilities, including yearly line assessments to provide effective methods in handling your adhesive solution and operator training whenever necessary.

Contact a Bostik expert today to get started with how our innovations can help you!

Ready to find the right adhesive solution for your equipment?

©2024 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

*Based on internal testing

Back to Top

Heat Seal Extruding Solutions

Reseal Extruding Solutions

Why Work With Bostik

Cold Seal Coating Solutions

Heat Seal Coating Solutions

Reseal Coating Solutions

Laminating Adhesives Coating Solutions

EXTRUDING Solutions

Bostik offers heat seal and reseal for extruding equipment.

Bostik's Extruded Solutions

Bostik's solutions for coating equipment are cold seal, heat seal, reseal and laminating adhesives.