Innovative Liftgate Solutions

For a One-Stop-Shop Approach to Assembly

©2024 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

Pliogrip™ and Thermelt® are trademarks of a member of the Arkema Group.

Ready to choose a one-stop-shop approach to liftgate assembly?

Designed for panel to panel bonding, Pliogrip™ structural adhesives have been a reliable

solution for over 50 years, helping enable:

Panel to Panel Bonding

Panel to panel bonding

Fixed Back GLass Bonding

Liquid Masking

Electronic Encapsulation

Why Bostik

Pliogrip™ structural �adhesives offer robust bonding �to a wide range of substrate �metals and composite materials �such as glass-filled polypropylene, thermoplastic polyolefins (TPO), �e-coat to metal, polycarbonate, glass and sheet molded compound (SMC). They are also suitable for dirty, oily surfaces and uncoated metal substrates and possess bonding capabilities to low CLTE �substrates, such as TPO.

As an OEM, it can be challenging to meet performance, processing and sustainability goals when also project managing different materials from different suppliers. By choosing Bostik as your one-stop-shop adhesive and sealant liftgate supplier, it’s easy. Find out how our innovations can help you for:

Our Recommended Technology: Pliogrip™ Structural Adhesives

Improved Performance

With little to no priming

required, Pliogrip™ structural adhesives provide fast initial strength at room temperature to reduce complexities and speed up production time.

Efficient Processing

Enhance Sustainability

Bostik’s Pliogrip™ structural adhesives are suitable for bonding dissimilar substrates, offering one reliable solution for plastic, glass and metal. Additionally, they offer primerless adhesion to LSE thermoplastics.

What really makes Bostik’s Pliogrip™ structural adhesives innovative?

By offering solutions for four key liftgate assembly applications, Bostik helps you easily rely on one supplier for your liftgate bonding and sealing needs. Additionally, as a global, Arkema company, we have supply security to get you the products you need when and where you want them. This helps you reduce production complexities and streamline your assembly efforts.

Further, by choosing Bostik for your liftgate adhesive and sealant needs, you’ll receive:

The Value in a One-Stop-Shop Liftgate Adhesive/Sealant Supplier

Contact a Bostik expert today to get started with how our innovations can help you!

Pliogrip™ structural adhesives’ gravity feed capabilities allow you to get the most out of your materials by using your entire drum supply. These adhesives also offer room temperature dual cure or fast heat acceleration, helping to reduce your facility’s overall energy consumption.

Our SMP solutions

have elastic properties, providing high bond strength and flexibility that enables them to decrease overall vibration and protect against expansion or contraction.

Improved Performance

As a primerless solution,

our SMPs help reduce production steps and error likelihood that could lead to downtime. Additionally, dual component booster is available in customized formulations to reduce

cure time.

Efficient Processing

Our SMP solutions are isocyanate-free, helping improve worker and facility safety compared to products that contain isocyanates.

Enhance Sustainability

Our SMP solutions serve as a hybrid technology, combining the advantages of both adhesives and sealants to fixed glass bonding applications and offering:

Our Recommended Technology: Silyl Modified Polymer (SMP)

Fixed Back Glass Bonding

Bostik's SMP solutions are dispensed at room temperature, allowing for reduced equipment cost and less energy consumption. They also offer gravity feed capabilities enabling you to use the entire supply and reduce material waste.

What really makes Bostik’s SMP innovative?

Our structural adhesives are available in acrylic, polyurethane and epoxy technologies.

As a robotically-applied, polymer solution, it replaces traditional masking tape to minimize material waste and labor costs, helping streamline your processes and reduce overall waste expenses.

What really makes Bostik’s liquid masking innovative?

Comprised of 100% solids, our liquid masking helps reduce solvent usage, resulting in less carbon emissions.

Enhance Sustainability

Our liquid masking can offer an 18-month shelf life, which helps extend the supply usage timeframe to reduce re-ordering frequency.

Efficient Processing

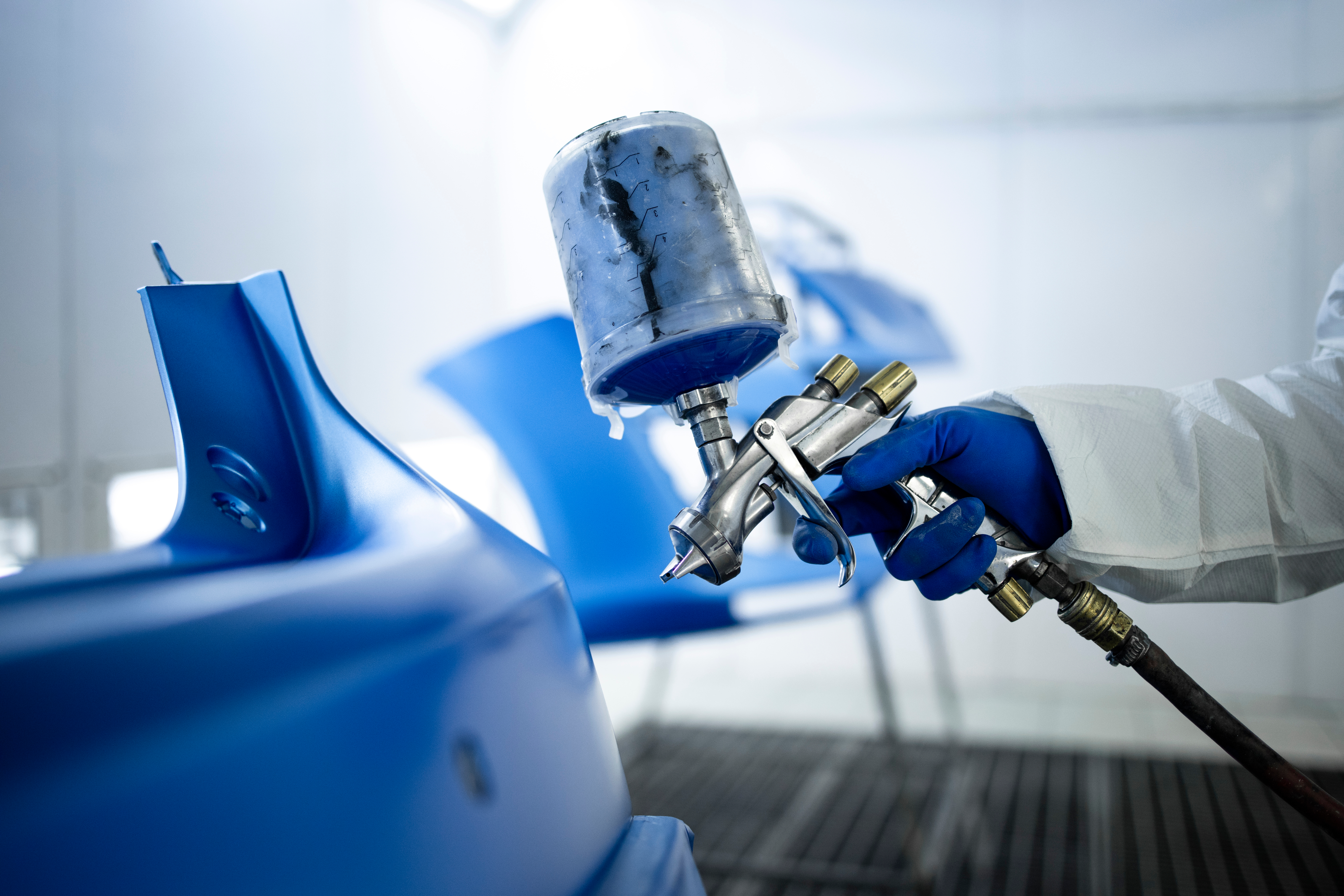

Our liquid masking �povides excellent resistance against chemicals, grease and plasticizers. It can also withstand high temperatures from the paint bake oven and comes in a wide range of viscosities and

softening points.

Improved Performance

Offering strong adhesion to heated metals and plastic substrates, liquid masking enables:

Our Recommended Technology: Hot Melt Adhestives

Bostik's Liquid Masking

Bostik offers additional features that can be integrated with your LPM adhesives, such as our patented, methoxyethyl cyanoacrylate (MECA) monomers that offer less reaction time compared to competitors.* This allows us to reduce odors and blooming, providing a more flexible monomer that can pair with our LPM adhesives for well-rounded protection and bonding.

What really makes Bostik’s Thermelt® LPM adhesives innovative?

As a solventless solution, �our Thermelt® LPM adhesives help reduce carbon emissions compared to traditional solutions that contain solvents. They also are made from bio-sourced materials to help improve fuel emissions.

Enhance Sustainability

Our Thermelt® LPM

adhesives possess fast cycle times of 90 seconds to keep production lines moving. They also are a one-component solution; no mixing is required, which further increases production efficiencies while also reducing reduce error likelihood.

Efficient Processing

With both low viscosity

and temperature range levels, our Thermelt® LPM adhesives enable low process pressure for electronic components that have delicate materials

or heat sensitivity.

Improved Performance

Suitable for protecting electronic components such as rear lighting, back-up sensors and cameras, our Thermelt® LPM adhesives are compatible with plastics, metals and ceramic substrates, offering:

Our Recommended Technology: Thermelt® Low Pressure �Molding (LPM) Adhesives

Electronic Encapsulation

*Based on internal testing

Customized formulations: We’ll help you develop solutions that include key performance criteria for your specific application needs.�

Dedicated technical service: We’ll support you throughout the entire process of testing, trial work and product startup to ensure our solutions perform successfully. We also offer state of the art analytical services for troubleshooting any issues that may arise.�

Sustainable solutions: We are continually developing new options to help you improve lightweighting and reduce solvent usage.

Panel to Panel Bonding

Liquid Masking

Electronic Encapsulation

Fixed Back Glass Bonding

Pliogrip™ Structural Adhesives

Hot Melt Adhesives

Silyl Modified Polymer (SMP) Technology

Thermelt® Low Pressure Molding (LPM) Adhesives