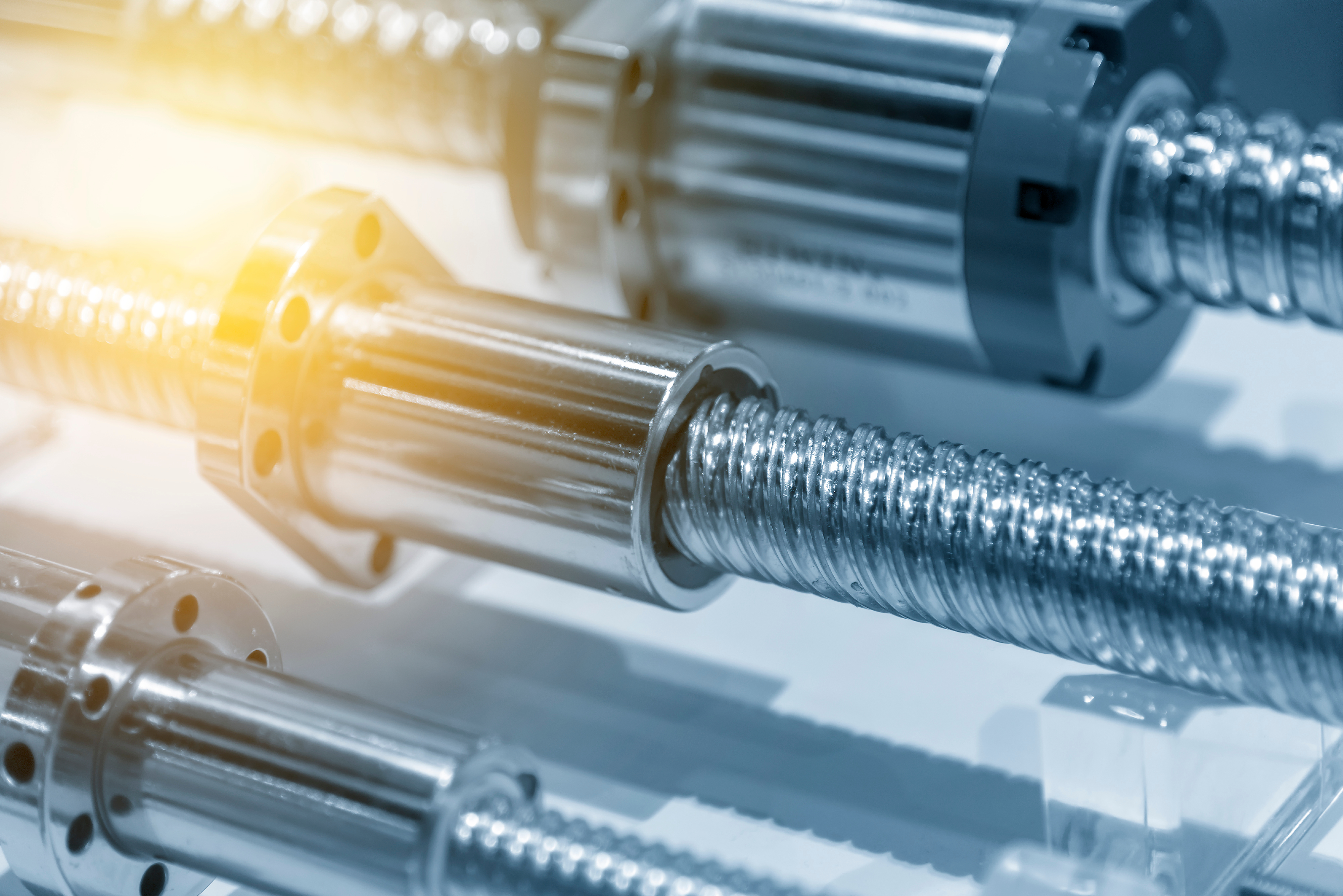

When addressing MRO maintenance issues with thread lubricants, it’s critical to use an anti-seize compound that helps you:

Increase protection

Reduce friction and error likelihood

Streamline efficiencies

For over 50 years, Bostik’s Never-Seez® products have helped our customers assemble and disassemble threaded connections in industrial environments. However, we understand it may be challenging to determine whether you need Never-Seez® Regular Grade or a Never-Seez® grade that’s formulated for a specific application need.

Use this guide to help you navigate our Never-Seez® product line and choose the right option for your MRO maintenance requirements.

Bostik's Never-Seez® Solutions

Choose the Right PRODUCT GRADE for You

All of Bostik’s Never-Seez® solutions are designed to help you:

Know the Never-Seez® Product Options

Determining the Right Specialized Never-Seez® Grade

Never-Seez® FAQ

How Bostik Can Help

Know the Never-Seez® �Product Options

Reduce friction and error likelihood: Never-Seez® compounds help you disassemble machinery, piping and metal parts without destruction and decrease the potential for thread distortion, exposure effects and galvanic corrosion that can result in galling and seizure.

Increase efficiencies: Never-Seez® compounds decrease downtime and production costs with their spreadability, providing up to 6,480 in2 coverage per lb. based on 4 mil. film thickness.*

*Based on internal testing

Increase protection: Never-Seez® compounds seal metal components under extreme heat and pressure, providing long-term protection against corrosion, galling, seizing and pitting after exposure to various environmental factors such as temperatures, chemicals

or moisture.

Never-Seez® Regular Grade offers a wide range of protection against corrosion, rusting, pitting, seizure and galling, which is why it serves as our most popular MRO maintenance solution. However, there are situations where a specialized option should be considered instead. Click on each Never-Seez® product to learn when to consider a specialized grade.

Determining the Right Specialized Never-Seez® Grade

Never-Seez® Pure Nickel Special

Recommended when applications need higher heat and chemical resistance than Regular Grade

Meets GE Aviation A50TF198 S2 Specification and GE EMPIS D6Y28C1 Specification

Protects parts in heat up to 2400°F (1315°C)

Never-Seez® Nickel Nuclear grade

Recommended when nuclear power plant applications require high-purity products

Meets GE Nuclear Energy D50YP12 and D50YP5B Specification as well as GE EMPIS D6Y6C1 Specification

Protects parts in heat up to 2400°F (1315°C)

Never-Seez® High temperature stainless

Recommended when application cannot include nickel-based materials

Contains no copper or aluminum

Protects parts in heat up to 2200°F (1204°C)

Never-Seez® High Temperature Stainless Nuclear Grade

Recommended when nuclear power plant applications require high-purity products yet cannot include nickel-based materials

Contains no copper or aluminum

Protects parts in heat up to 2200°F (1204°C)

Never-Seez® Blue Moly

Recommended when applications cannot include graphite but are compatible with nickel

Handles extreme pressure involving heavy loads and slow speed

Protects parts in heat up to 1500°F (815°C)

Never-Seez® Mariner's Choice

Recommended when applications need soft metals that can handle exposure to salt water and moisture

Lowest torque factor for soft metals �

Prevents seizure at heat up to 2450°F (1343°C)

Never-Seez® Pipe Compound with PTFE

Recommended when using pipe and fitting applications

Allows strong thread engagement and sealing

Protects parts in heat up to 525°F (273°C)

Never-Seez® Black Moly

Recommended when an assembly paste with no metal materials is needed for application

Handles extreme pressure involving heavy loads and slow speed

Protects parts in heat up to 750°F (398°C)

Never-Seez® White Food Grade with PTFE

Recommended when application may come into food contact and needs to meet FDA requirements

Registered NSF H1 Food Grade

Lubricates in heat up to 475°F (246°C)

Never-Seez® Regular Grade

Recommended for general protection against corrosion, rusting, pitting, seizure and galling

Meets GE EMPIS D6Y28A1 Specification

Protects parts in heat up to 1800˚F (982°C)

Never-Seez® High Temperature Bearing Lubricant

Recommended when using wheel bearing applications

Contains no metallic particles

Protects and lubricates parts in heat up to 1000°F (537°C)

Click on the questions below to gain an understanding of common questions you may have about how to best use Never-Seez® products.

Never-Seez® FAQ

How do I clean-up or remove Never-Seez®?

Using a cloth or paper towel can help wipe out or remove the majority of Never-Seez®. In order to clean up the residual oil or grease, we recommend solvent paint thinners such as mineral spirits or odorless mineral spirits (OMS), as they are more chemically compatible with the grease carrier or base oil compared to acetone or methyl ethyl ketone (MEK).

How do I apply Never-Seez® for proper torque?

How do I clean-up or remove Never-Seez®?

How do I find the date of manufacture on my Never-Seez® product?

How do I apply Never-Seez® for proper torquing?

When Never-Seez® is properly applied, the assembled bolt can be reinstalled. This reduces replacement costs and maintenance downtime, because you don’t need to obtain and install a new one. Read the steps below to learn how to apply Never-Seez® for proper torquing.

Step 1: Apply Never-Seez® to the base of the threads. Ensure full circumference is covered. There is no need to coat the full length of the threads.

Step 2: Screw the nut on the bolt all the way up the shaft. Then, unthread it off to fill in the anti-seize between the bolt and threads. This helps ensure proper coverage for effective lubrication.

Step 3: Apply Never-Seez® under the bolt head before installing.

Pro tip: Be sure to apply Never-Seez® on both the threads and bolt cap. This will allow you to achieve maximum tightening with the least amount of torque.

You can also watch this video to learn how to apply our Never-Seez® Regular, High Temperature Stainless Nuclear and Pure Nickel Grades.

How do I find the date of manufacture on my �Never-Seez® product?

You can find the seven-digit lot number and the six-digit date code printed on the bottom of the Never-Seez® can. Bostik recognizes the item packaged date as Date of Manufacture, i.e., beginning of shelf life. The Date Code is labeled as a year-date-month; for example, a Date Code of 230210 indicates the Date of Manufacture is 02/10/2023. For a production batch made before May 2010 from Bostik Marshall Plant, the lot number and date code are printed on the right bottom corner of the label.

How Bostik Can Help

Our technical service team is here to help with addressing your specific MRO maintenance needs. From answering product questions and providing guidance for proper application methods, to helping determine the correct solution, we provide expertise to help ensure a seamless experience with our Never-Seez® products.