For over 50 years, Pliogrip™ structural adhesives have offered reliable bonding solutions to materials commonly used in composite and dissimilar material bonding:

Pliogrip™

Structural Bonding Adhesives

Pliogrip acrylic adhesives are designed for bonding FRP composites in marine, wind transportation and general assembly applications. They can bond to dirty, oily surfaces and offer performance advantages due to their ability to adhere to a wide range of substrates metals and composite materials with little to no surface preparation. These products provide fast initial strength at room temperature and are ideal for uncoated metal substrates.

Pliogrip™ Acrylic Adhesives

• Fiber reinforced plastic (FRP)

• Carbon fiber reinforced plastic (CFRP)

• Thermoplastic polyolefins (TPO)

• Polyamide

• Metal (steel or aluminum)

Available in acrylic, polyurethane and epoxy technologies, find out how Pliogrip adhesives are the right choice for your needs.

Features & Benefits

Little to no surface preparation

Simplifies production steps

Click the below features to learn the benefits.

High strength bonding

Removes need for mechanical fasteners

Low bond line read-through

Minimizes surface distortion

Fast room-temperature cure

Eliminates oven or special equipment needs

Compatible Materials

Fiber reinforced plastic

(FRP)

Carbon fiber reinforced plastic (CFRP)

Metal

(steel or aluminum)

Used for bonding composite materials and coated metals in automotive, truck, marine, farm equipment and recreational vehicle applications, Pliogrip polyurethane adhesives meet or exceed certain OEM safety requirements. These two-part, 100% solids and reactive systems offer excellent chemical and moisture resistance when cured. They work well for processes that require fast strength build and short fixture time and can help streamline operations.

Pliogrip™ Polyurethane Adhesives

Features & Benefits

Click the below features to learn the benefits.

Excellent impact resistance

High sag resistance

Imperceptible shrinkage

Wide range of fixture times

Improves durability

Enables precision bonding capabilities

Enhances dimensional stability

Provides variety of processing options

Compatible Materials

Fiber reinforced plastic

(FRP)

With Pretreatment

With Only

Coated Materials

Excellent heat acceleration

Increases productivity for various assemblies

• Sheet Molding Compound (SMC)

• Carbon fiber reinforced plastic (CFRP)

• Polyamide

• Thermoplastic polyolefins (TPO)

• Polypropylene (PP)

• Metal (steel or aluminum)

Little to no surface preparation

High strength bonding

Low bond line read-through

Fast room-temperature cure

Excellent impact resistance

High sag resistance

Imperceptible shrinkage

Wide range of fixture times

Excellent heat acceleration

Pliogrip epoxy adhesives are engineered to meet specific high heat and design requirements for the structural assembly of composite or metal substrates. Made of 100% solids, these two-part, reactive epoxy technologies provide durable bonds on assembled parts.

Pliogrip™ Epoxy Adhesives

Features & Benefits

Click the below features to learn the benefits.

High temperature paint baking

Bare metal bonding

Superior chemical resistance

Toughened formulation

Endures e-coat processes up to 410°F (210°C)

Eliminates protective coating need

Resists chemical exposure in various applications

Strong impact resistance

Compatible Materials

Fiber reinforced plastic

(FRP)

• Sheet Molding Compound (SMC)

• Carbon fiber reinforced plastic (CFRP)

• Resin transfer molding (RTM)

BARE OR COATED METALS

• Steel or aluminum

WITH PreTREATMENT

• Thermoplastic polyolefins (TPO)

• Polypropylene (PP)

High temperature paint baking

Bare metal bonding

Superior chemical resistance

Toughened formulation

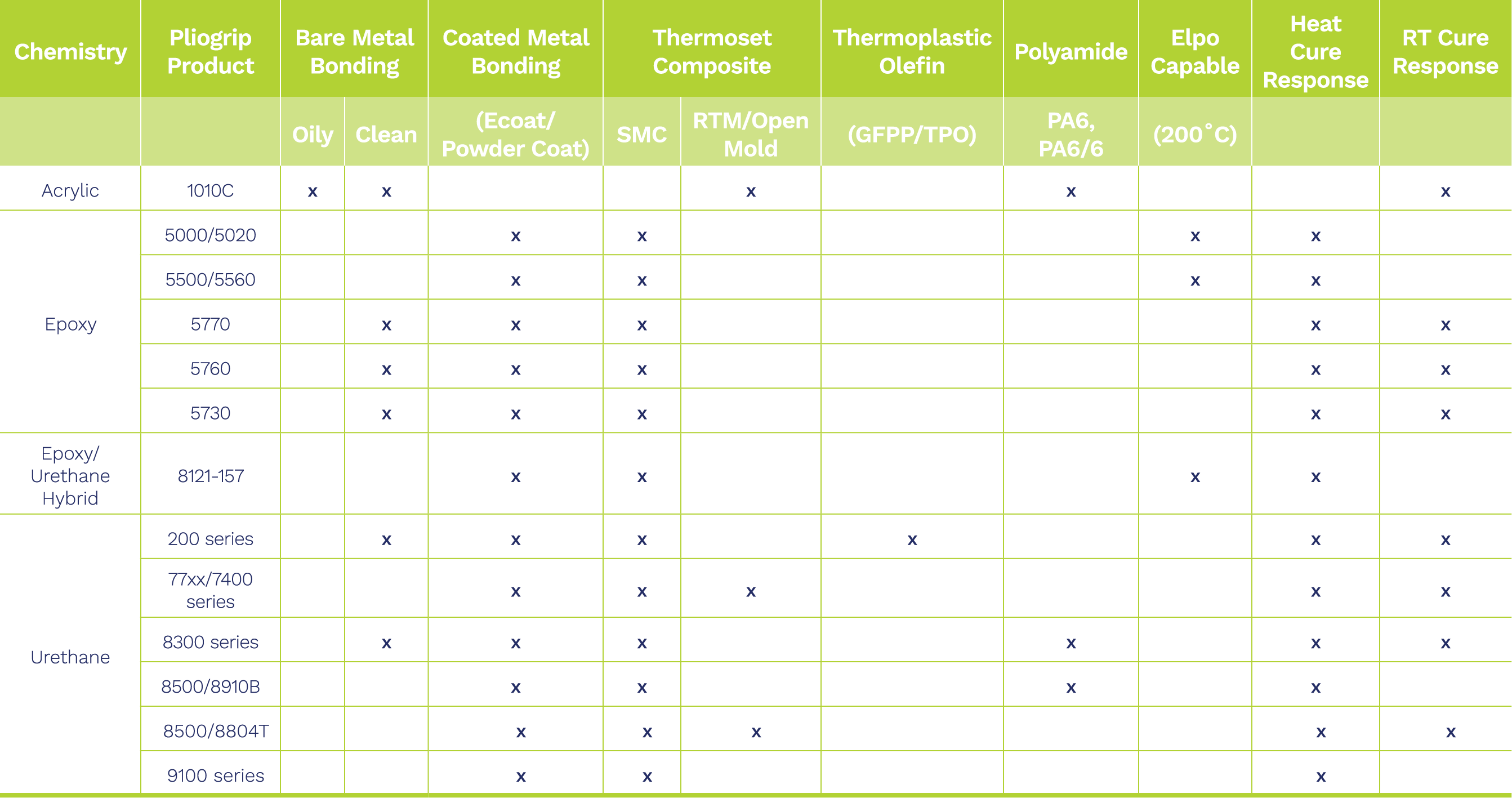

Use the flow chart to determine your specific application needs and find out learn what solutions are recommended most

Product Selector

Carbon Fiber Reinforced Plastic (CFRP)

Polyurethane

Recommended technologies:

Substrate: Fiber Reinforced Plastic (FRP) Composite

Recommended Technologies: Acrylic, Polyurethane and Epoxy

Why:

• Fast heat cure response

• Minimized surface preparation

• Superior chemical resistance

How to choose a specific technology:

•

•

•

Choose acrylic adhesives for their durability when you don’t have heated fixtures and need high strength building at room temperature.

Choose polyurethane adhesives for their self-leveling capabilities and sag resistance when you need vibration or impact resistance.

Choose epoxy adhesives for their excellent chemical resistance, especially for dissimilar material bonding when you need the part to go through the

e-coat process.

Thermoplastic Polyolefins

(PP/TPO)

Recommended technologies:

Low Modulus Polyurethane

Metal Bonding

(Steel or

Aluminum)

Recommended technologies:

Polyurethane and Epoxy

Learn Why

Learn Why

Learn Why

Why:

•

•

•

Dissimilar material bonding

Excellent adhesion

Low bond line

read-through

•

•

•

Low surface energy compatibility

Excellent adhesion

High impact resistance

Why:

•

•

•

High heat resistance

Fast strength build

Short fixture time

Why:

Learn How to Choose

a Technology

•

•

Choose polyurethane adhesives for their ability to bond dissimilar metal materials, especially when fast strength build and short fixture time are necessary.

Choose epoxy adhesives for their ability to endure e-coat processes up to 410°F (210°C) when you need high temperature paint baking.

How to choose a specific technology:

It is important to consider the substrate performance and processing requirements in your end-use application to ensure you’re choosing the right structural adhesive.

Choosing the Right Pliogrip Structural Adhesive Technology

Bare

Metal

Coated

Metal

Thermoplastic Olefins

(GFPP / TPO)

Polyamide

Sheet Molded Compound (SMC)

Open Mold, RTM Composites

Acrylic,

Epoxy,

Urethane

Urethane, Epoxy

Urethane

Urethane, Acrylic

Urethane, Epoxy

Acrylic, Urethane

1010C acrylic, 5770,

5760,

5730 epoxy, 200 series, 8300 series urethane

77xx / 7400 series,

9100 series, 200 series urethanes, 5770,

5760,

5730 epoxies

200 series

8500,

8300 series urethane, 1010C acrylic

9100 series, 8500 series, 77xx/7400 series urethane, 5500/5560, 5000/5020 epoxy

1010C acrylic, 77xx/7400, 8500 series urethane

Because Bostik’s Pliogrip portfolio is based on acrylic, polyurethane and epoxy technologies, you have the ability to choose which structural adhesive formulation is right for you. You also receive:

Why Work with Bostik

•

•

•

Technical Support: From start of testing to trial work/product startup, we are with you along the entire process and offer state of the art analytical services for troubleshooting.

Customized Formulations: Our experts develop modified solutions that maintain key performance features and work with your specific processing or application needs.

Sustainable solutions: Our portfolio includes solutions with reduced solvents, helping you increase vehicle lightweighting.

©2023 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

Contact a Bostik expert today to learn how Pliogrip structural adhesives can enhance your manufacturing needs.

Pliogrip™ Acrylic Adhesives

Pliogrip™ Polyurethane Adhesives

Pliogrip™ Epoxy Adhesives

Choosing the Right Pliogrip Structural Adhesive Technology

Product Selector

Why Work with Bostik

Table of Contents

Pliogrip™ Acrylic Adhesives

Pliogrip™ Polyurethane Adhesives

Pliogrip™ Epoxy Adhesives

Choosing the Right Pliogrip Structural Adhesive Technology

Product Selector

Why Work with Bostik