With a wide portfolio of adhesive technologies, Bostik is vertically integrated to meet your specific panel lamination bonding needs for pre-fabricated and modular systems. When you work with us, you’ll receive:

Why Choose Bostik for Panel Lamination Adhesives

Technical Expertise: Our team will work with you to find a suitable solution for your existing manufacturing equipment while offering high performance.

Innovative Solutions: Integrate advanced technologies into your manufacturing that bridges market gaps between you and installers.

Sustainable Improvements: We are continually implementing ways to improve your materials durability and widen the breadth of sustainable substrates to be used.

Roll Coater

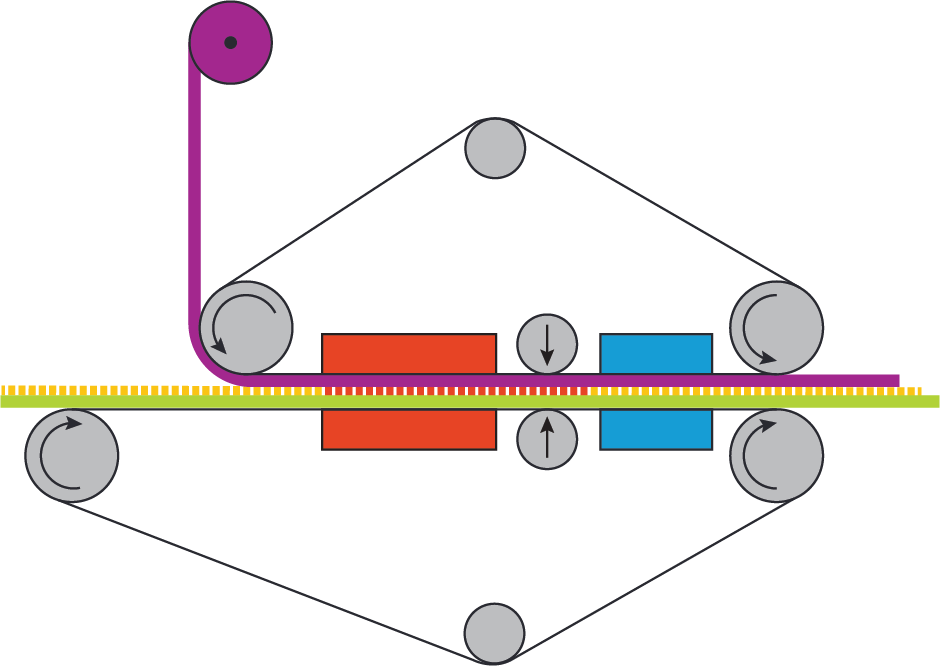

MCPUR is typically applied through a roll coater on one or both sides at a variety of coat weights. Water is then sprayed on to the adhesive. Once placed in the stack, the adhesive cures. Pressure is applied to mitigate foam expansion throughout the curing process.

Substrate type: Rigid sheets

Processes: Adjustable cure times

Adhesive application: Extruded, spattered, swirl coated

Hot pressing: Not required, but can be used

MCPUR Lamination Equipment and Processing

Ask us about ISOGRIP™

As a one-component, 100% solid, ICC-ES-recognized solution for structural insulated panels, patio enclosures, exterior entry doors and more, ISOGRIP™ is designed to offer superior strength to provide long-lasting durability.

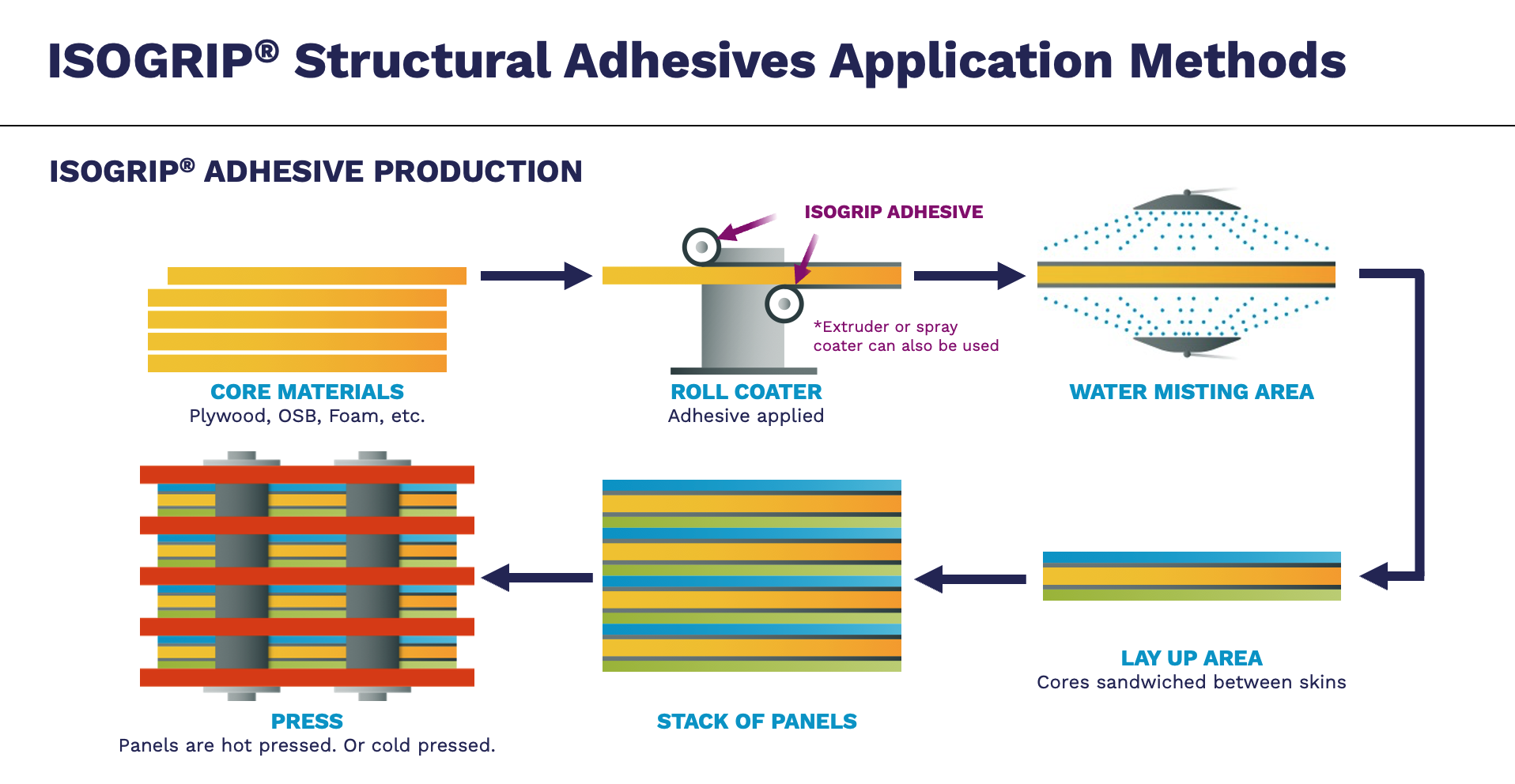

This image demonstrates how ISOGRIP™ is implemented into processing methods:

One-component, 100% solids formulations to provide ease of production

Thermosetting to form a strong bond

Excellent creep, water, heat, chemical and humidity resistance to provide long-term bonding

Broad range of curing speeds to suit various processing requirements

What it offers:

Structural Polyurethane

Technology

Designed to address durability and structural performance needs while conforming to building code requirements.

Liquid, Moisture-Cure Polyurethane Adhesives (MCPUR)

Heat sensitive material: Compatible

Melting requirements: Preheated with IR oven and/or under belt pressure with recommended heat and line speed

Powder: Use scatter coater for pre-application

Adhesive application: Unroll adhesive in selected geometry (thickness and width)

Processes: Continuous or semi-continuous, medium speed, varying widths

Substrate type: Rolled goods, continuous sheets, individual panels

Flat substrates are bonded together using heat and pressure. The heat and pressure are applied through opposing conveyor belts, compressing two substrates, which “sandwich” an adhesive layer to form a bond.

COMPATIBLE PACKAGING: FILMS, WEBS, POWDERS

Flatbed/Belt Laminator

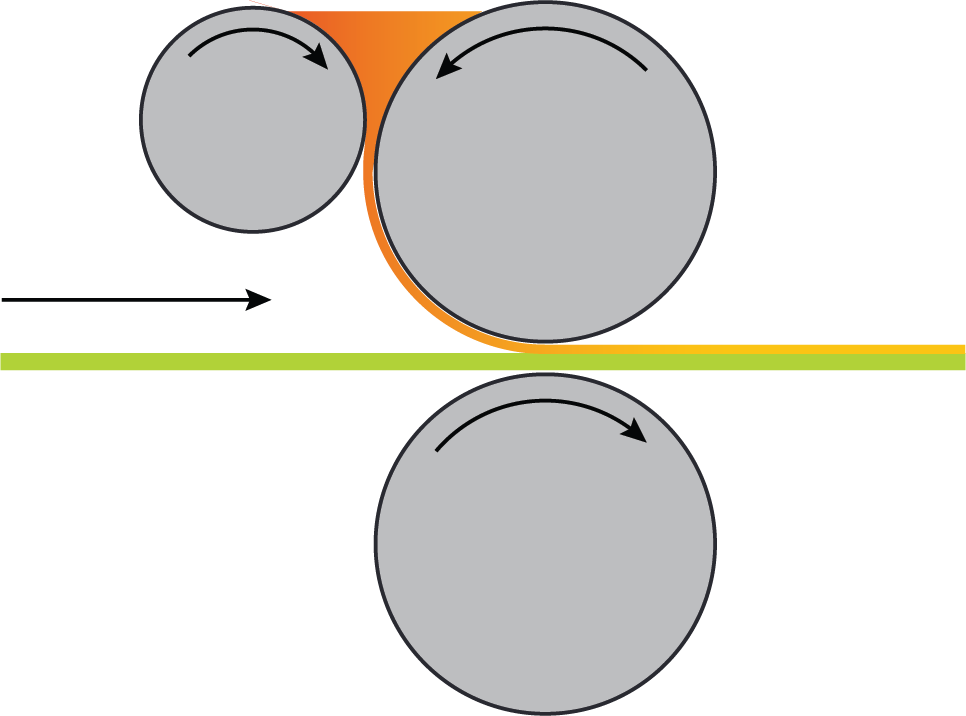

Roll Coating

COMPATIBLE PACKAGING: PELLETS, COEX PILLOWS, BULK

This equipment has a series of compression rollers with a primary heated roller that takes molten hot melt adhesives and coats them onto a primary substrate (either rigid or flexible).

Substrate type: Rolled goods, semi-stiff continuous sheets, individual rigid panels

Processes: Continuous or semi-continuous, medium speed

Adhesive application: Apply pooled, molten hot melt adhesive via rollers to primary substrate in thin-coat or pattern.

Melting requirements: Pre-melted in tank/extruder and pumped into rollers, direct melt on rollers

Heat sensitive material: Compatible

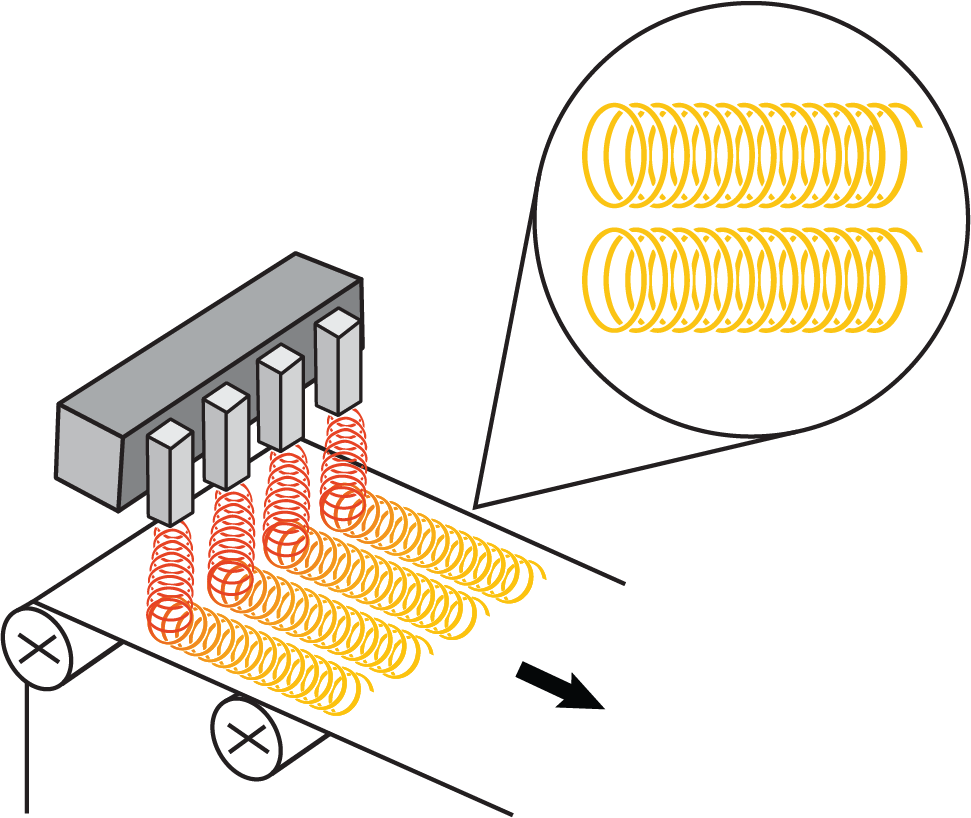

Spiral Spray

COMPATIBLE PACKAGING: PELLETS, COEX PILLOWS, BULK

The spiral spray process applies molten adhesives in a spiral-like fiber pattern, yielding a large adhesive coverage surface area. This process allows for porosity and breathability in the adhesive layer.

Substrate type: Rolled goods, continuous and individual sheets

Processes: Continuous, high-speed, varying widths

Adhesive application: Fiberized in random or spiral pattern

Melting requirements: Melt tank, drum unloader, extruder

Heat sensitive material: Compatible

Hot Melt Lamination Equipment and Processing

Ask us about Thermogrip®

These thermoplastic hot melts make up a robust product line offering support for a variety of applications and technological needs.

Our thermoplastic hot melts are available in the following formats:

Pellets

Powders

Webs

Films

Broad processing window

Wide tack level range

Easy handling with minimal equipment

Why?

If you need versatility to meet a wide range of application needs, choose thermoplastic hot melts.

Choosing the Right Hot Melt Technology

This one-component, reactive hot melt polyurethane product line offers excellent green strength and versatile substrate bonding to wood, fiberboard, steel, plastics, ABS, foam and flexible vinyl. These products are available in pails and drums for commercial sale and other formats for sampling.

Ask us about Supergrip®

If you need strong performance for demanding applications, choose reactive polyurethane hot melts.

Why?

Excellent temperature resistance

Good elasticity and strength balance

Strong bonding for dissimilar substrates

Choosing the Right Hot Melt Technology

Excellent green strength to adhere to a wide variety of substrates, including common core materials

UV and chemical resistance to prolong durability

Various form factors to cater to your application demands

Fast curing and consistent linear coating to increase production efficiencies

What they offer:

Reactive Polyurethane Hot Melts Thermoplastic Hot Melts

Technologies

Designed to address various strength, durability and property needs in pre-fabricated and modular markets.

Hot Melt Adhesives

As a construction OEM in the pre-fabricated and modular markets, it’s critical for your panel lamination materials to prevent racking and moisture within wall and modular systems for a long-lasting product.

The right adhesives can make it easy.

Bostik’s full portfolio of hot melt and liquid, moisture-cure polyurethane (MCPUR) panel lamination adhesives help ensure your residential and commercial panels meet performance demands while maintaining economic production processes.

With Bostik’s Panel Lamination Adhesives

Improve Pre-fabricated Walls and Modular Systems

Assessing Adhesive Technology Capabilities

Why Choose Bostik for Panel Lamination Adhesives

Hot Melt Adhesives

Liquid Moisture-Cure Adhesives (MCPUR)