From everyday households to clinics and hospitals, medical-grade pressure sensitive adhesives (PSAs) are used for quick, safe solutions to minor cuts or injuries. Therefore, it is critical that all medical-grade PSAs provide:

Pressure Sensitive Adhesives

For Medical Applications

©2023 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

Are you interested in learning how our PSA technologies easily address skin contact time and sensitivity needs? Contact a Bostik expert to see how our adhesive solutions can benefit your application and processes.

Based on hot melt, specialty solution acrylic and waterborne acrylic, Bostik’s PSAs:

Introducing Our PSA Solutions...

Introduction & Applications

Testing Requirements

How to Choose the Right PSA

Why Bostik

• Excellent skin adhesion

• Flexibility

• Residue-free removal from skin

• Sweat, blood and water resistance

• Breathability for healing

Learn how Bostik’s PSA solutions make it easy for you to ensure your medical-grade adhesive-coated constructions meet these requirements.

Enhance product design and customization options

Streamline manufacturing processes

Improve sustainability

Key Applications:

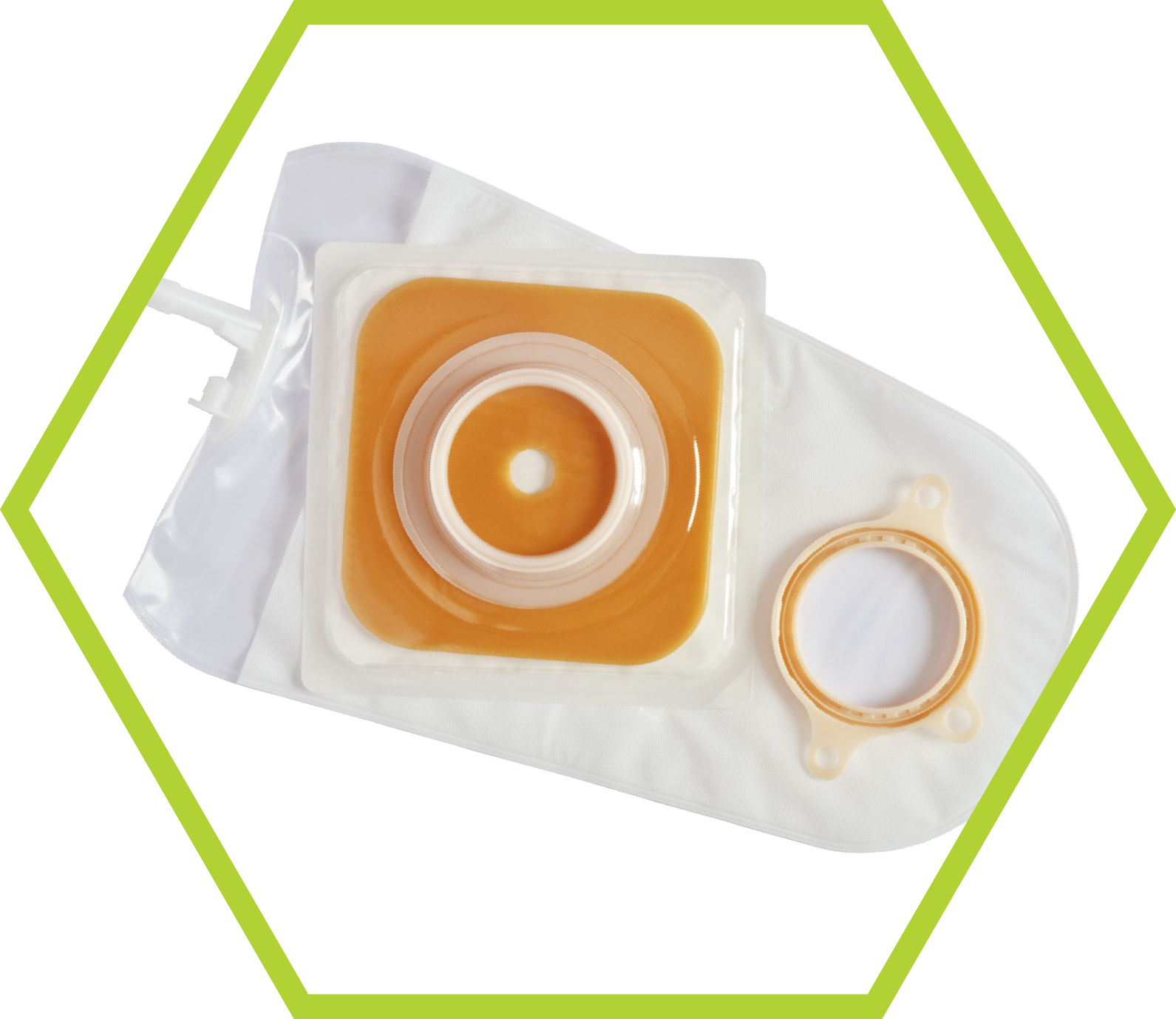

Ostomy Care Products

Bandages

Diagnostic Devices

Medical Tapes

Nasal Strips

Wound Care

...That Meet Key Testing Requirements

Our PSAs have passed compulsory skin-contact requirements including cytotoxicity, primary dermal irritation and sensitization tests under ISO 10993 (or similar) standard methods. This helps to ensure that you’re providing a safe adhesive construction that will pass the necessary ISO testing prior to the launch of your medical grade product.

In particular, our medical grade PSAs pass the necessary ISO testing for:

• No cytotoxicity (10993-5)

• Non-sensitizing (10993-10)

• Non-irritating (10993-10)

Additionally, we safeguard our adhesives by going beyond the polymer and testing the entire adhesive technology to ensure prevention against cytotoxicity, sensitivity or irritation. This will help your testing processes move along efficiently.

It’s important to know whether a hot melt, specialty solution acrylic or waterborne acrylic PSA is right for your end-use application needs. Once you assess your coating equipment capabilities, ask yourself if you require:

How to Choose the Right PSA for You

Device Backing Versatility

Longer-term adhesion (2 weeks+)

Short-term adhesion

Low residual monomers

Recommended technology: Hot Melt

Why? Able to bond broad variety of substrates, including water-repellent fabrics and polyethylene foams without surface treatment

Recommended technology: Specialty Solution Acrylic

Why? High sweat and oil resistance during skin contact

Recommended technology: Waterborne Acrylic

Why? Cost-effective for applications designed for minor cuts or injuries

Recommended technologies: Specialty Solution Acrylic or Hot Melt PSAs

Why? Excellent skin irritation resistance

Technical Expertise

Why Choose Bostik as Your

PSA Supplier

As the adhesives solutions segment of the Arkema group, Bostik is empowered by Arkema’s global manufacturing footprint and R&D capabilities. Bostik’s products come with full technical support, working with our customers throughout all steps of trialing and troubleshooting during production.

Supply Security

Bostik is vertically integrated to provide you with the raw materials necessary to help ensure your PSA will perform efficiently and help increase your production speeds. This will help you keep processing steps moving along without waiting for key materials to arrive at your facility.

Cost Savings

Suitable for PU films, foams and nonwovens, our PSAs can be easily used with equipment you already own, decreasing downtime by utilizing the same adhesive on your production lines for all your applications including hot melt (slot-die), specialty solution acrylic (knife or roll coating and waterborne acrylic (meyer rod or gravure coating).

Additionally, our PSAs are warranted up to a one-year shelf life and can be ordered in small quantities, helping you regulate your inventory based on your supply needs.

Thermogrip®, Aroset™ and Flexcryl™ are trademark products under the Arkema company.

Our Aroset™ waterborne acrylic PSAs contain no solvents and provide high processing speeds to help you deliver more products in less time.

Many of our Aroset™ specialty solution acrylic PSAs are formulated with a high solids content to minimize use of resources and ease your carbon footprint.

Our Thermogrip® hot melt PSAs can help you streamline energy usage as a solventless solution. We can also modify hot melt formulations with bio-based raw materials to reduce carbon emissions.

Sustainable Solutions