When protecting electronic parts for end-use applications across markets, you may already be using low pressure molding (LPM) processes to reduce environmental impact compared to other common encapsulation methods. However, you may not know that when the right solutions are chosen, such as Bostik’s Thermelt® low pressure molding polyamides, you can experience increased sustainability advantages in addition to improved product performance overall.

Thermelt®

Bostik’s Bio-Based,

Low Pressure Molding Polyamides

For low pressure molding applications, Thermelt® is supplied as a resin that gets melted and injected into a mold to encapsulate electronic parts, including:

Introducing Thermelt®

Introducing Thermelt®

How Thermelt® Improves Sustainability

How Thermelt® Improves Product Performance

How to Choose the Right Thermelt® for You

Why Work With Bostik

Connectors

Onboard

Electronics

Light-Emitting Diode (LED)

Printed Circuit Boards (PCBs)

Thermelt® low pressure molding technology also works well encapsulating and protecting electronic components used in consumer electronics, medical devices, automotive sensors, connectors, charging stations and battery management systems.

LPM processes inherently allow you to do skylining, which reduces overall product weight and size compared to other encapsulation methods and helps reduce fuel consumption during product transportation. Additionally, LPM is a simple, three-step process designed to keep production lines moving and energy usage minimized. When Thermelt® is used, you may further reduce environmental impact and enhance efficiencies by:

How Thermelt® Improves Sustainability

Eliminating Harmful Substances

Reducing Reliance on Fossil Fuels

Offering Fast Processes

Reducing Likelihood of Parts Damage and Waste Generation

Eliminating Harmful Substances

Reducing Reliance on Fossil Fuels

Offering Fast Processes

Reducing Likelihood of Parts Damage and Waste Generation

Thermelt® is free of solvents and isocyanates commonly found in potting technologies, helping protect workers and eliminate hazardous substances that contribute to carbon emissions.

Thermelt®’s core formulation element consists of rapeseed oil, enabling this solution to be comprised of 90% bio-based raw materials to reduce environmental impact.

Thermelt® low pressure molding technology offers fast cycle times of 90 seconds to increase process speeds and reduce energy usage.

Thermelt® offers a wide range of viscosity levels and temperatures (356°F (180°C) to 446°F (230°C)), helping to make it easy to address delicate or sensitive materials that could get damaged during manufacturing and require material replacements.

Thermelt® can also improve your end-use product performance overall by offering:

How Thermelt® Improves Product Performance

Thermelt® resists temperatures (-76°F to 302°F (-60°C to 150°C)), oil, water and UV to help enable a long-lasting electronic component.

Environmental resistance

Thermelt® insulates electronic parts for reliable thermal stability.

High electrical resistivity

Thermelt® has passed ISO certification tests to help ensure your chosen technology can withstand autoclave testing (up to 50 cycles) and withstand alcohol wiping and quick immersion. It also reduces sensitization or irritation likelihood that can occur with other products if in direct contact with skin.

Sterilization resistance to meet ISO certification

This rating means the product will self-extinguish within 10 seconds when exposed to a flame and won’t drip flaming particles for increased end-user safety.

UL 94 V-0 rating

ISO Certifications For:

Thermelt® 867:

ISO 10993-4

ISO 10993-10

ISO 10993-11

ISO 10993-23

Thermelt® 195:

ISO 10993-4

ISO 10993-5

ISO 10993-10

ISO 10993-11

ISO 10993-23

Additionally, the Thermelt® range is available in different Tg and adhesion levels to help you find a solution that meets your specific application performance requirements.

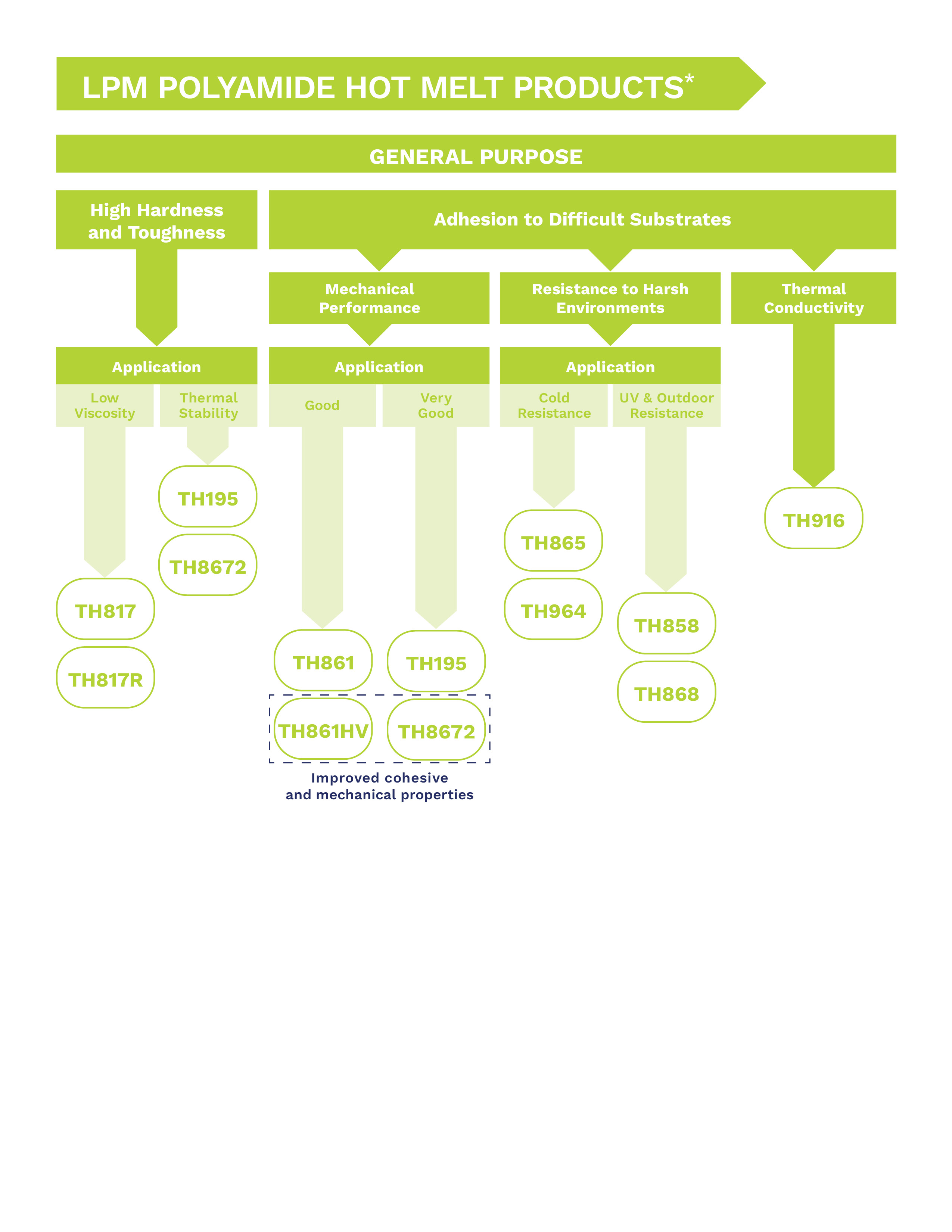

How to Choose the Right �Thermelt® for You

In addition to the broad Thermelt® low pressure molding technology portfolio, Bostik offers:

Technical support: From trial testing to troubleshooting assistance, our team members consist of low pressure molding experts and specialists who can offer in-person support with your assembly.

Trial testing: We work with you to test your materials with our product range, helping to ensure you find the best solution for your performance needs.

Troubleshooting: We assist helping you operate efficiently with Thermelt® on your production lines. We also offer support with product training and using automated dispensing equipment properly.

Reliable partnerships: We are here to develop relationships with equipment producers that help ensure your machinery operates efficiently with a high-performance adhesive solution like Thermelt®.

Global sourcing: Through our parent company Arkema, we are vertically integrated to provide Thermelt® low pressure molding technology across regions.

Thermelt® is a trademark of Arkema Group.

Why Work with Bostik

Additionally, LPM is a simple, three-step process designed to keep production lines moving and energy usage minimized.

Most products are available in natural and black

TH817 is available in stick form