At-A-Glance:

Bostik’s Window & Door Adhesive & Sealant Technologies

©2023 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

Pro-MS™, Thermogrip®, Isogrip™ and SuperGrip® are trademarks of the Arkema Group Company.

Contact a Bostik expert to discuss which adhesive or sealant technology is best for your specific window and door application needs.

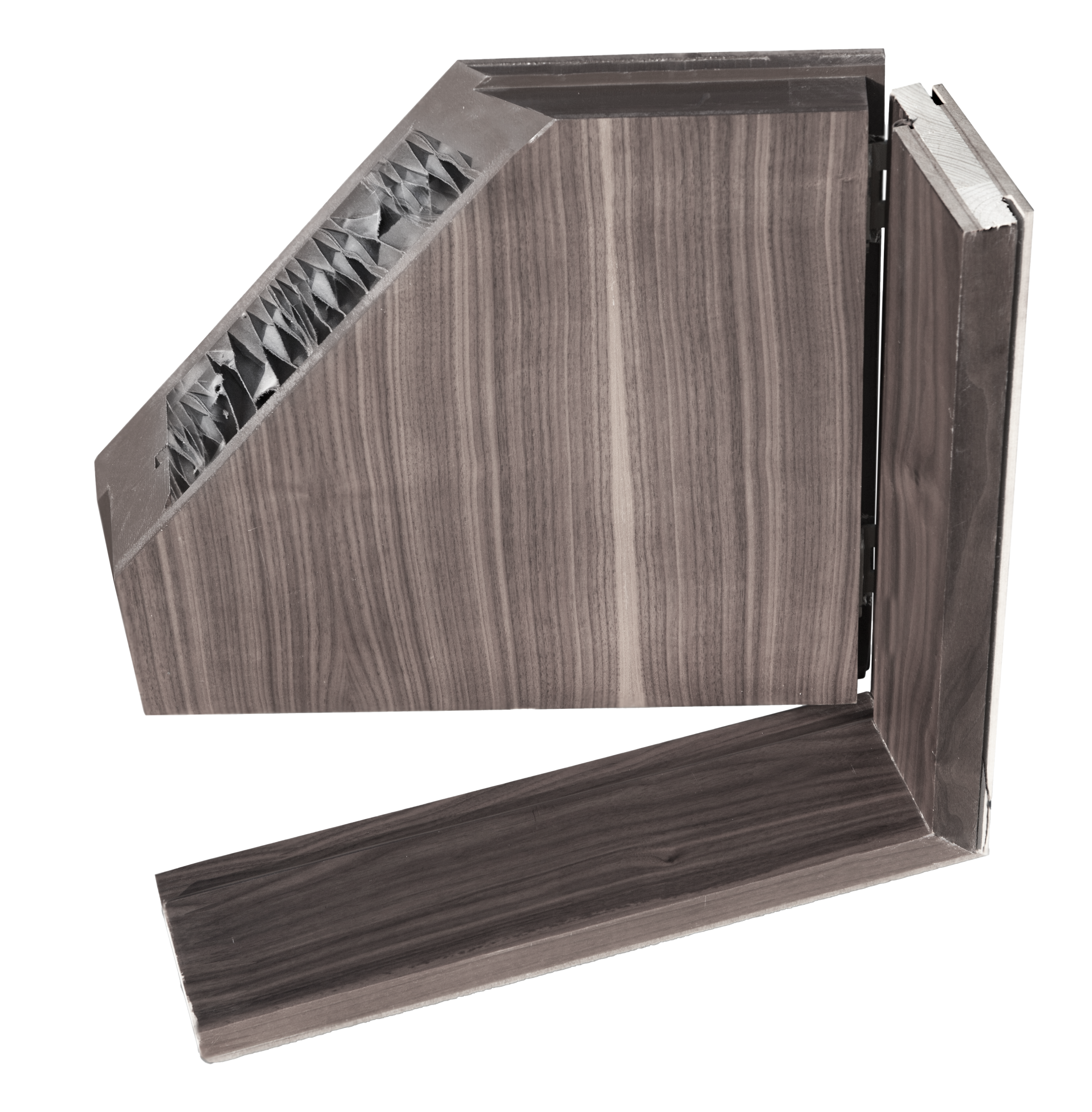

When manufacturing windows and doors, your bonding and sealing solutions play a critical role in the end-use application’s overall durability and aesthetics, while also impacting your production efficiencies and environmental footprint.

Therefore, it's important to ensure your chosen solutions offer:

• Strong adhesion or sealing capabilities

• Long-term outdoor exposure resistance

• Excellent processability

• Environmentally-friendly formulations

Bostik’s solutions make it easy with a technology portfolio based on one-component polyurethane (PUR), silyl modified polymer (SMP), hot melt, water-based as well as one-component moisture-cure and more.

Find out more about where our adhesive and sealant technologies are used and why they are ideal for each application.

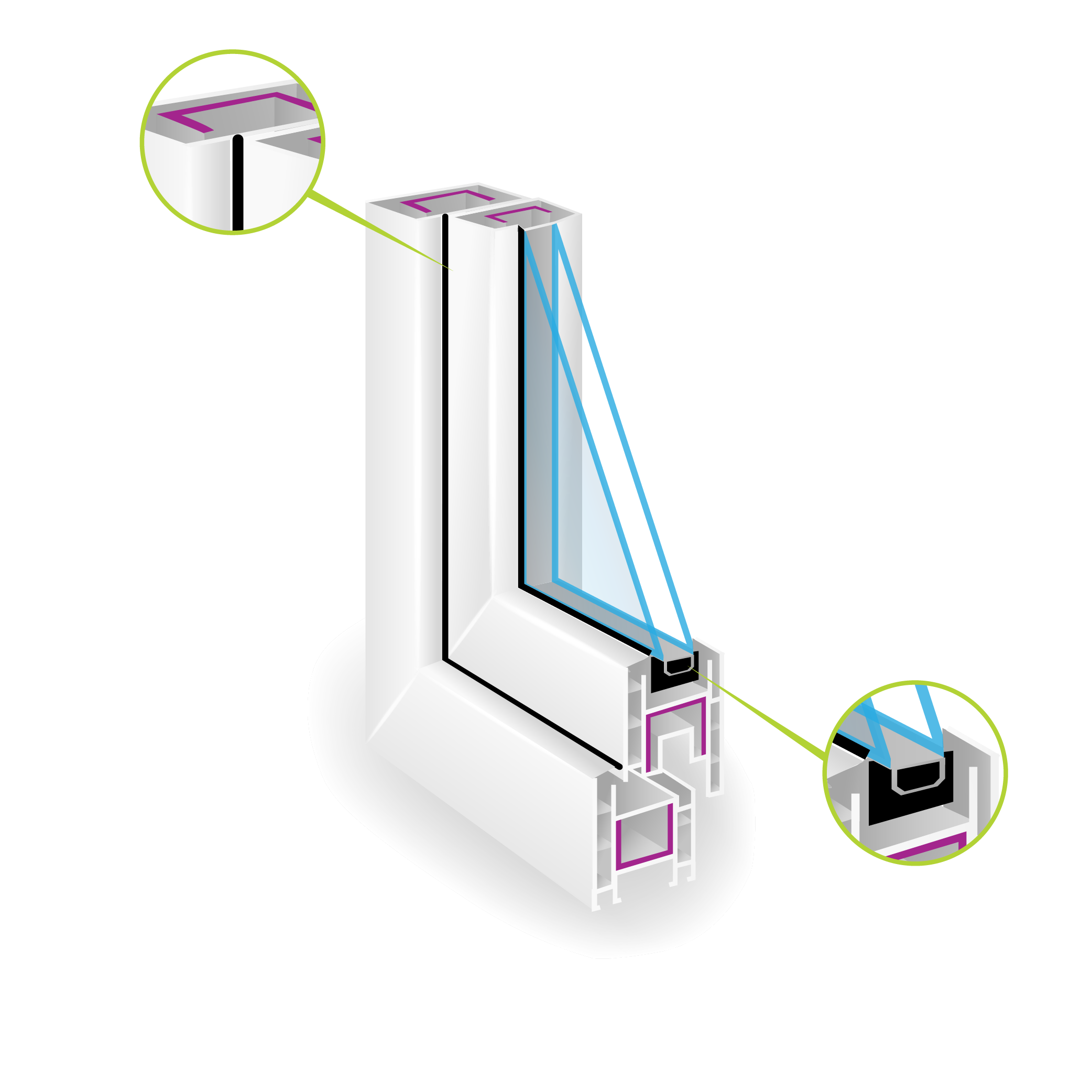

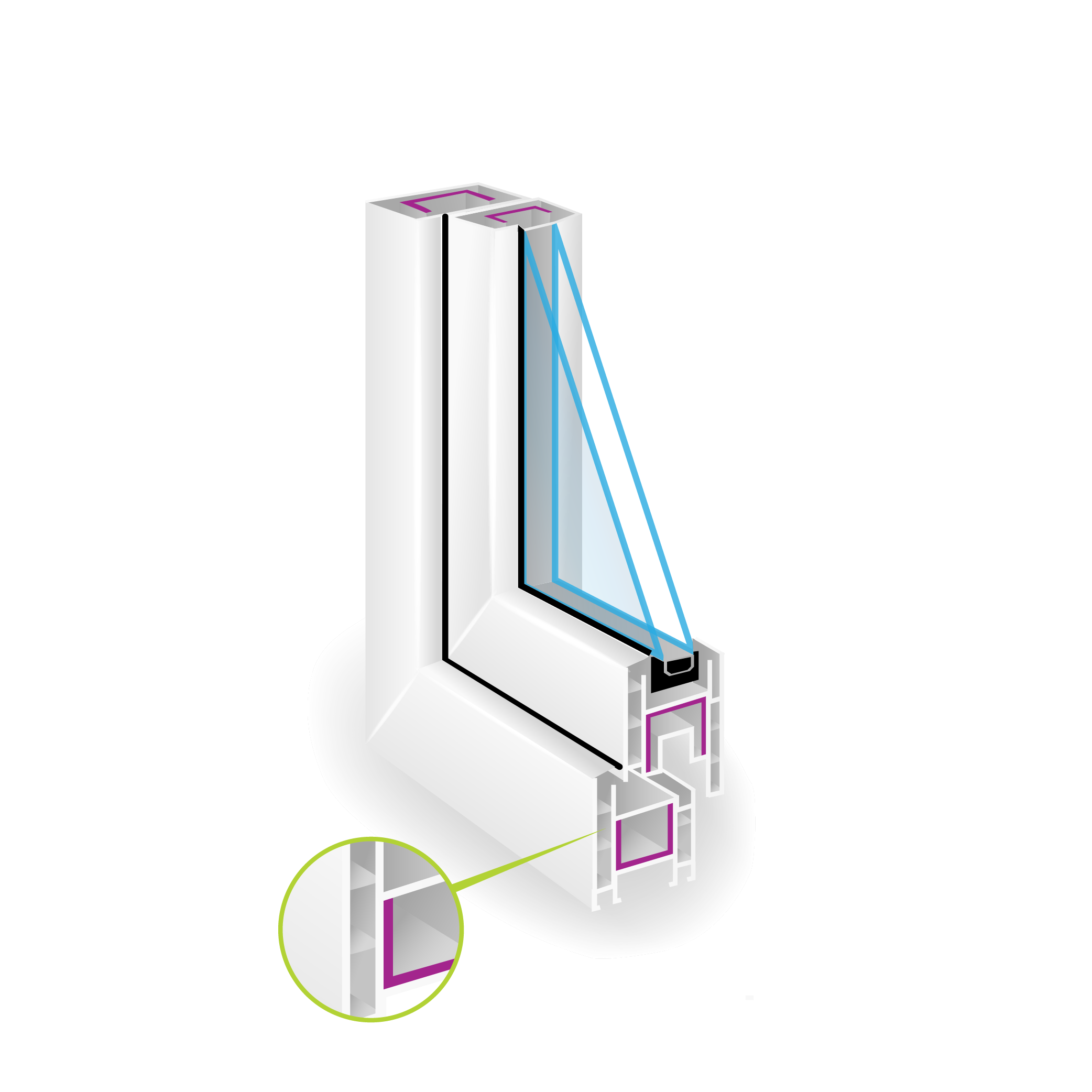

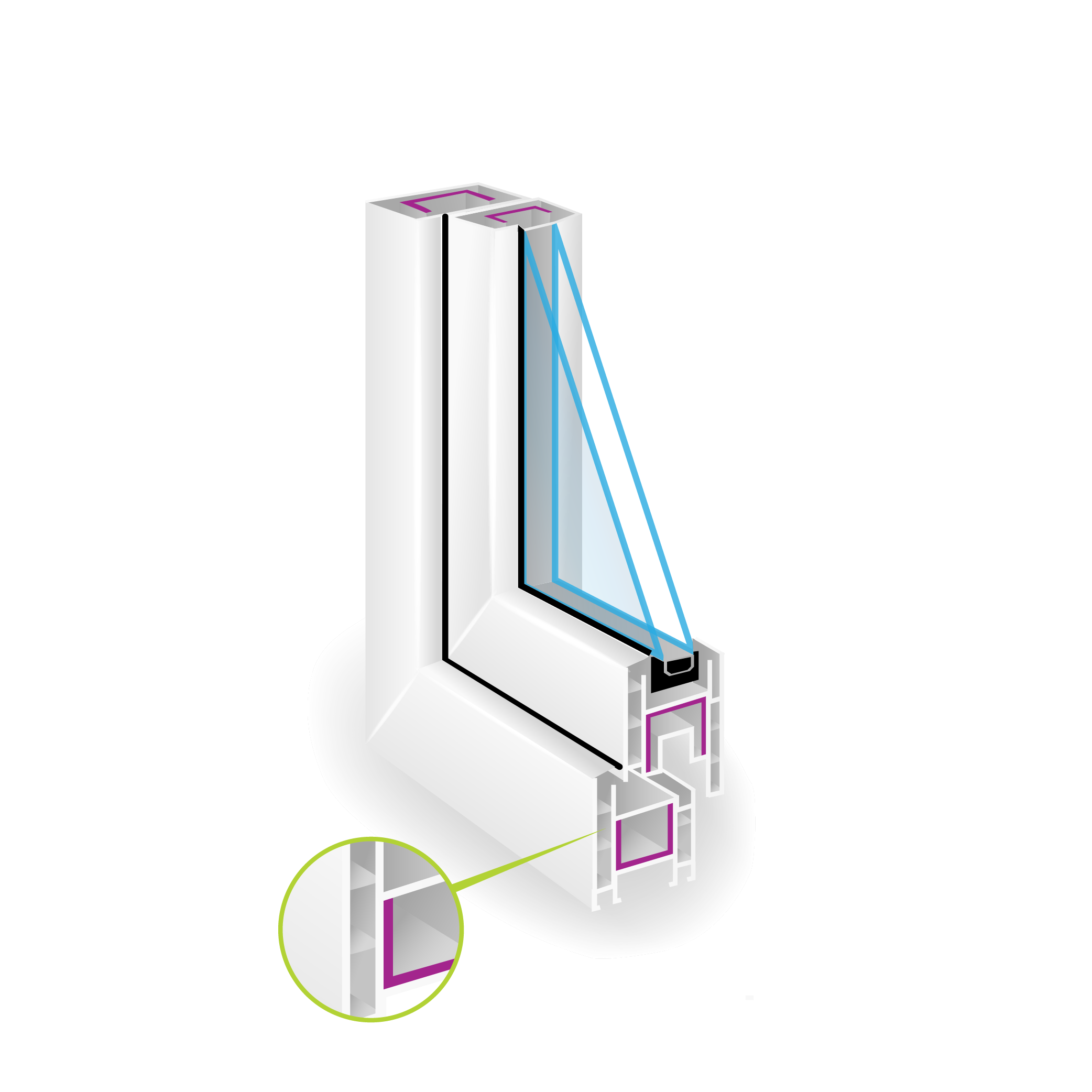

Foam-in-place

gasket

Technology: Hot Melt

• Heat resistance

• Excellent processability

• Fast setting

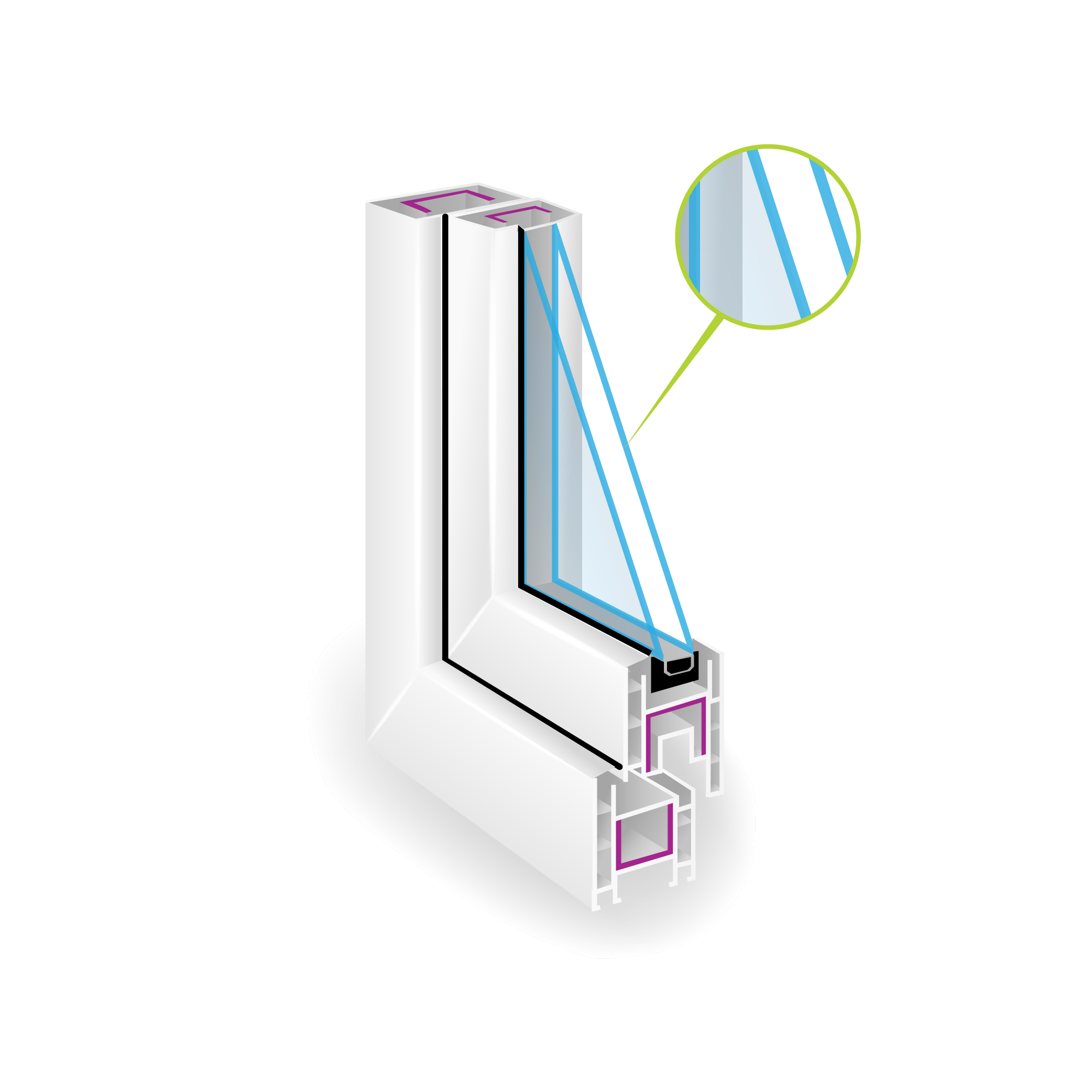

Backbedding/

glazing

Technology: SMP,

Hot Melt

• High green strength

• Excellent flexibility

• 100% solids

Stile and rail attachment

Technology: SMP, PUR, Hot Melt

• Excellent green strength

• Very good creep resistance

• Fast processing speeds

Accessory attachment

Technology:

One-Component

Moisture-Cure

• Excellent green strength

• Long open time

• Very good creep resistance

Millwork component

Technology:

Water-Based

• Excellent shrink resistance

• Long-term durability

• Wide application usage

Panel lamination

Technology: Hot Melt, One-Component Moisture-Cure

• Excellent green strength

• Long open time

• Very good creep resistance

Brick mould weatherproofing

Technology: SMP, PUR

• Excellent green strength

• Very good creep resistance

• Fast processing speeds

Technical Expertise

Our team will work with you to help find a suitable solution for your existing manufacturing equipment while offering high performance.

Innovative Solutions

Integrate advanced technologies into your manufacturing that bridge market gaps between you and installers.

Commitment to sustainability

We offer solutions that have low VOCs to improve energy efficiencies, helping reduce your overall carbon footprint.

When you work with Bostik, you’ll also receive:

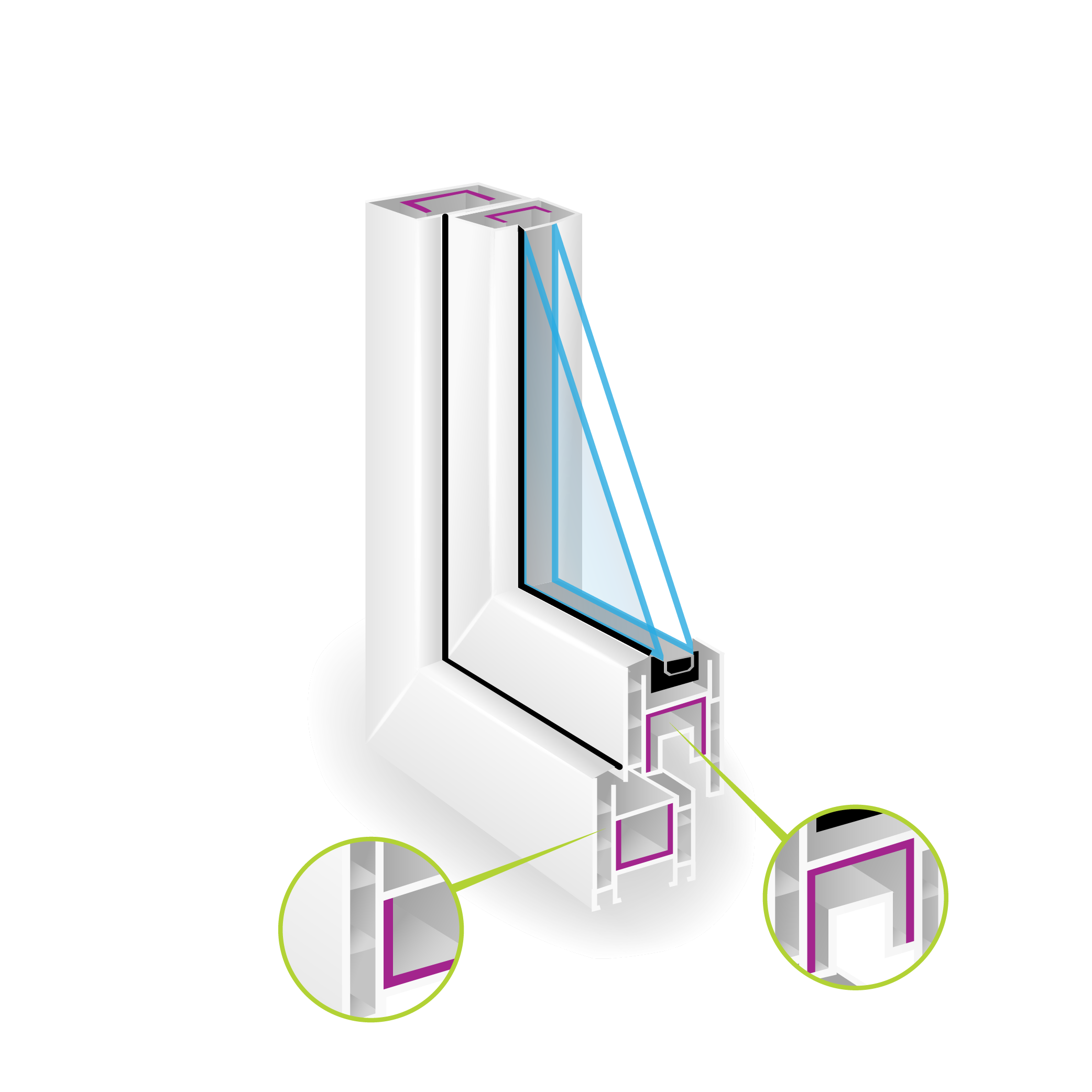

Backbedding/

glazing

Technology: SMP, PUR,

Hot Melt

• Fast setting

• High bonding strength

• Excellent durability

Profile wrapping

Technology: Powder, Film Pressure Laminating Adhesives

• Fast setting

• High bonding strength

• Excellent durability

Seam sealing

Technology: SMP

• Low viscosity

• Sprayable application

• Isocyanate-free

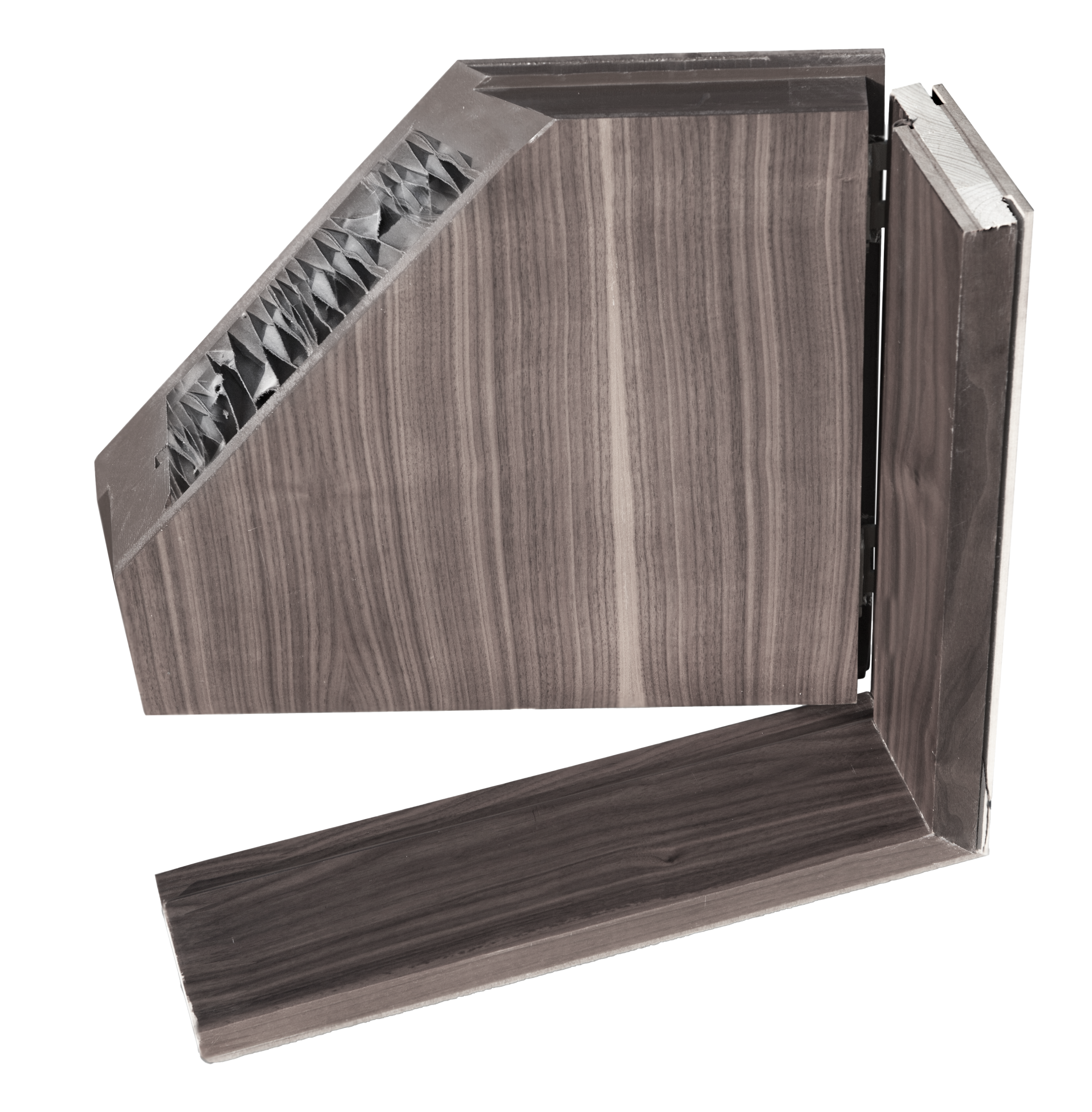

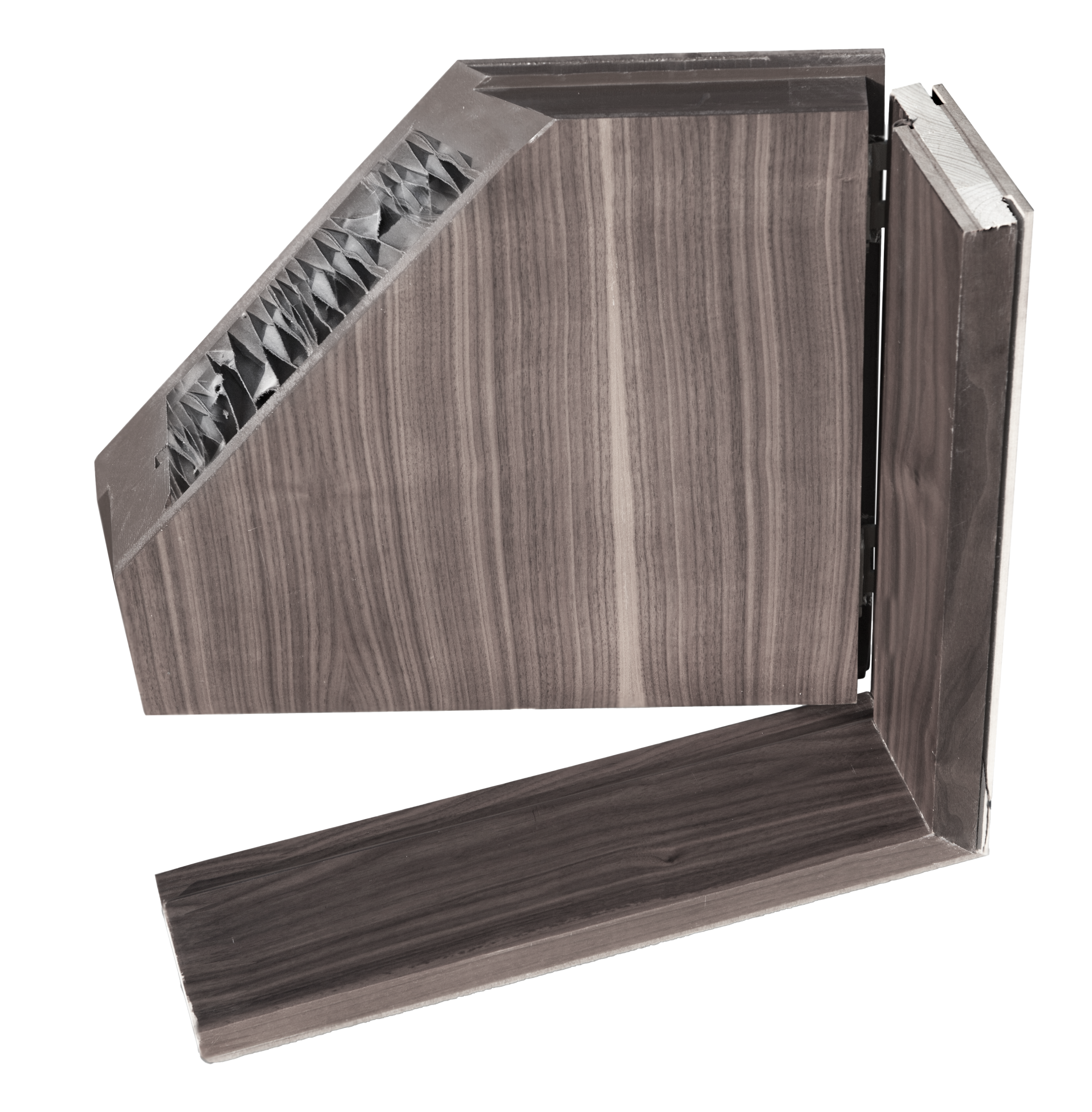

Corner key structural and weatherproofing

Technology: MMA, Hot Melt, PUR

• Fast setting

• High bonding strength

• Excellent durability

Cap stock sealing

Technology: SMP

• Fast setting

• High bonding strength

• Excellent durability