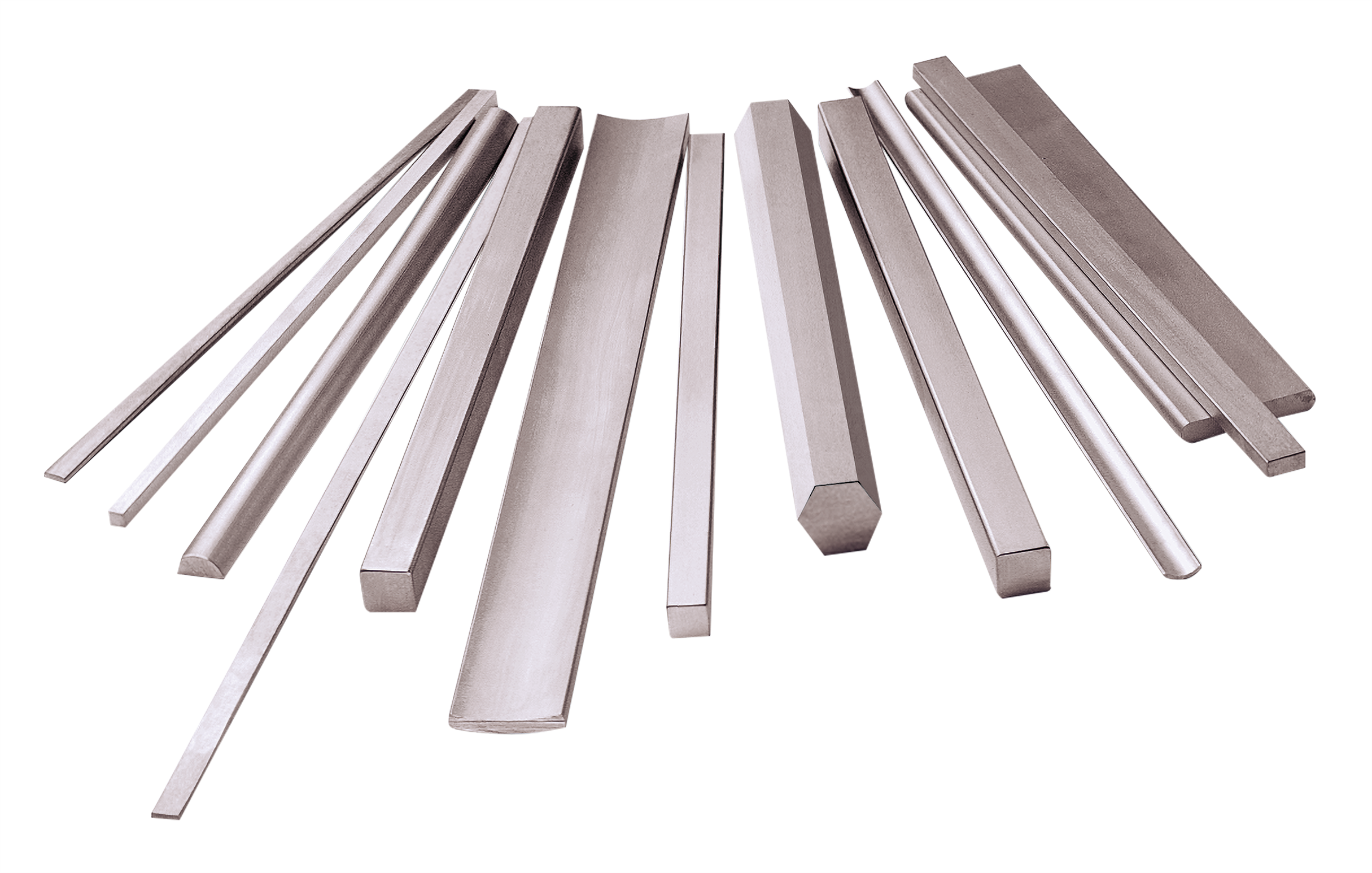

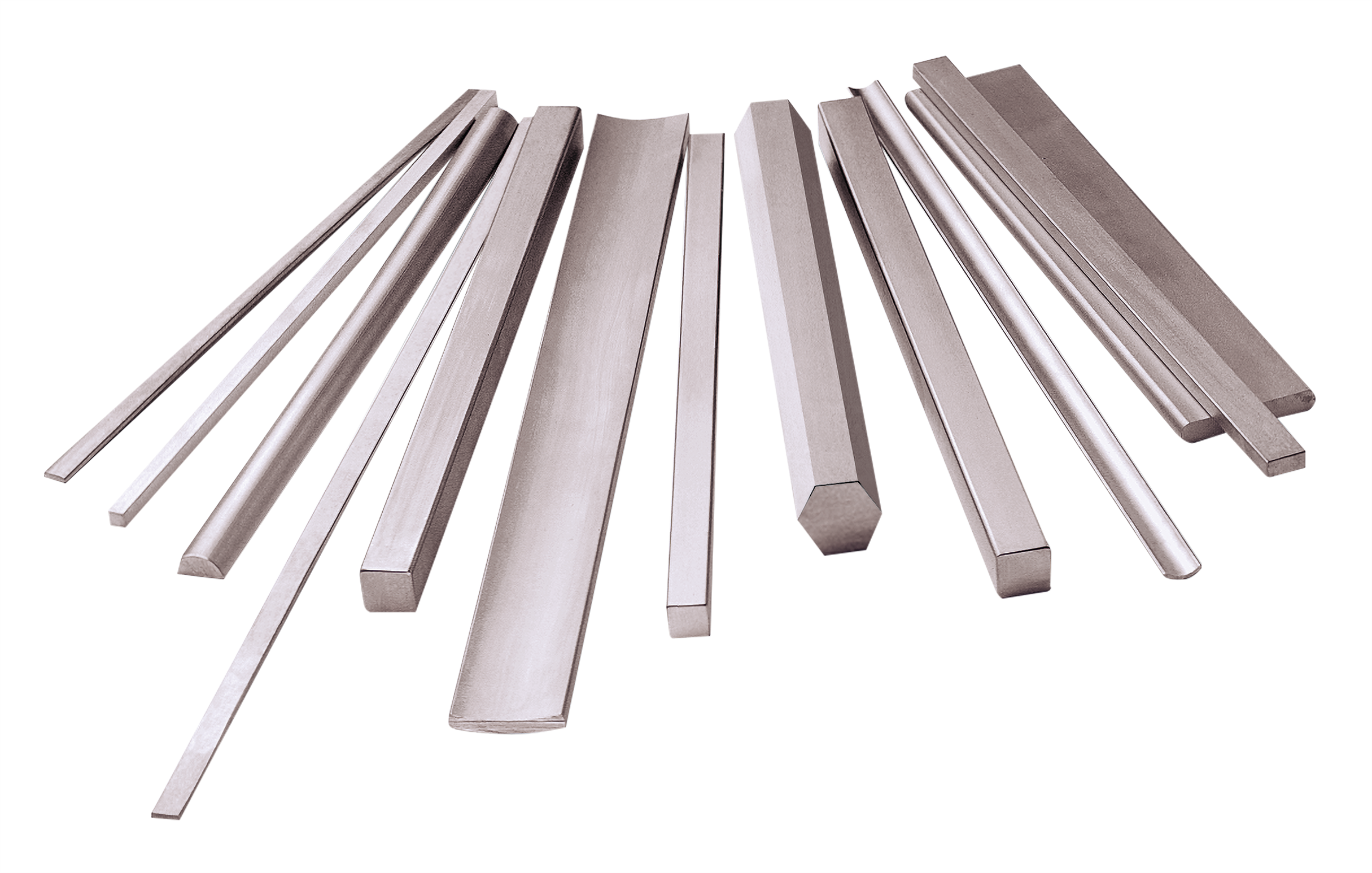

Premium metal in the forms you need

Cranking up patient outcomes since 1889

Life-changing materials

Carpenter Technology produces a range of alloys designed specifically for the rigors of orthopedic devices. Our low-cobalt stainless steels meet EU MDR standards and lead the industry in performance. Our small-diameter materials enable complex manufacturing and less invasive surgery.

Hardcore

alloys

Advanced

capabilities

High-performance, low-cobalt stainless steel alloys with superior strength and wear resistance meet the demands of new regulatory frameworks, surgical procedures, and production techniques.

Stainless. Limitless.

An EU MDR-compliant, nitrogen-strengthened, austenitic stainless steel, BioDur® 734 is ideal for implantable orthopedic parts with improved tensile, impact, and fatigue strength, and crevice and pitting corrosion resistance over BioDur® 316LS.

Breakthrough BioDur® 734

Explore orthopedic alloys

Download the datasheet

EU MDR-compliant to reduce patient exposure

Max strength and corrosion resistance with BioDur® 734

Industry-leading quality in a wide selection of forms

READ MORE

Hardcore alloys

Materials play a prime role in advancing orthopedics to positively impact patient outcomes, reduce procedural cost, meet the demands of new regulatory frameworks, and support an aging population.

EU MDR-compliant, low-cobalt stainless steel alloys answer the

call of the quickly evolving medical device industry.

High-performance materials meet the tight tolerances required for precision medical devices and enable minimally invasive surgeries and robotic-assisted procedures.

Tight dimensional tolerances and diameter uniformity

Unprecedented end-to-end manufacturing consistency

Cost savings + faster patient recoveries

READ MORE

Download the DATASHEET

WATCH THE WEBINAR

TALK TO AN EXPERT

Hardcore alloys

Advanced Capabilities

Talk to a medical-grade alloy expert

Talk to a medical-grade alloy expert

The landscape of the industry is changing with the new European Union medical device regulations (EU MDR). Essentially cobalt-free stainless steel compositions address the up-classification of cobalt as a Class II RMR substance.

Read the Blog

Low cobalt for EU MDR compliance

Low nickel for patient sensitivities

Exposure to nickel ions released from the normal wear of medical implants can lead to adverse effects for patients sensitive to the metal. BioDur® 108 offers an FDA-approved, essentially nickel- and cobalt-free alternative to other stainless options. Advanced cold-work capabilities allow us to tailor the mechanical properties of BioDur® 108 B and C, 316LS, and 465 to specific end uses.

WATCH THE WEBINAR

Small diameter. Big impact.

Advanced capabilities

As orthopedic device and surgical tools get smaller and more complex, material choices and manufacturing technologies become ever more crucial. Small-diameter alloys produce industry-leading performance and faster patient recoveries, as well as more efficient, cost-effective manufacturing.

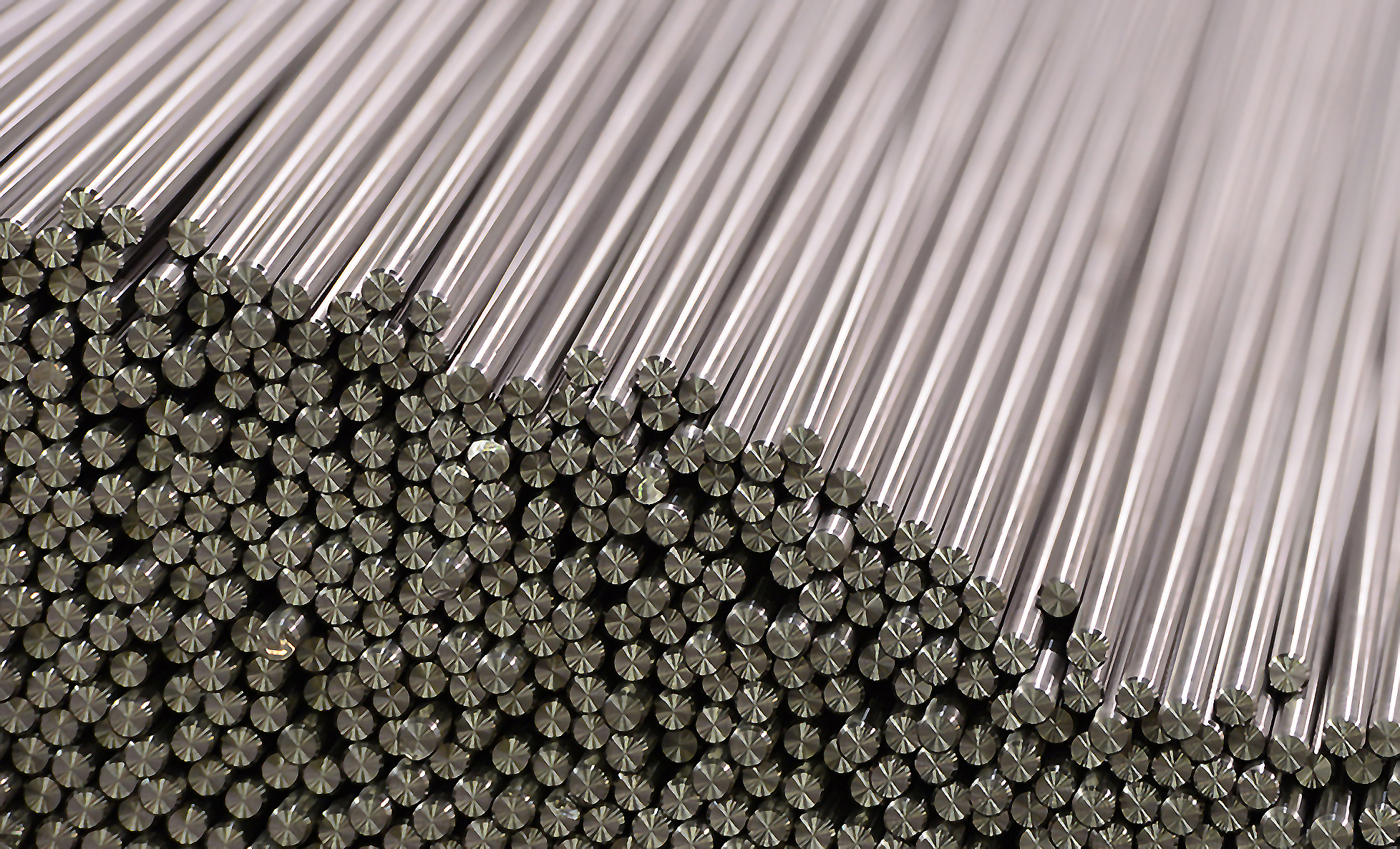

High-performance titanium

With stringent roundness, straightness, and finish requirements, small-diameter titanium delivers

tight dimensional tolerances with unprecedented consistency from end-to-end, bar-to-bar,

and lot-to-lot.

Discover Ti 6Al-4V ELI

Download the ultrabar fact sheet

Intricate cobalt alloy forms

Cobalt-based alloys provide exceptional wear and corrosion resistance, ultra-high tensile strength, and superior ductility and toughness. These properties are vital for creating small-diameter materials and complex forms for minimally invasive procedures.

Download the fact sheet

Download the white paper

Powder metallurgy processing

The Micro-Melt powder metallurgy process creates Micro-Melt® BioDur® CCM material with higher strength, enhanced fatigue resistance, increased hardness, improved microstructural uniformity, and finer grain size — allowing for the production of small-diameter stock and custom shapes.

Built for orthopedics

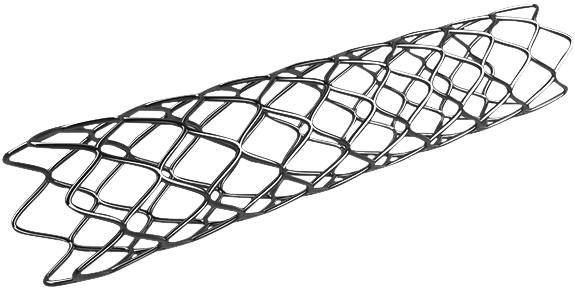

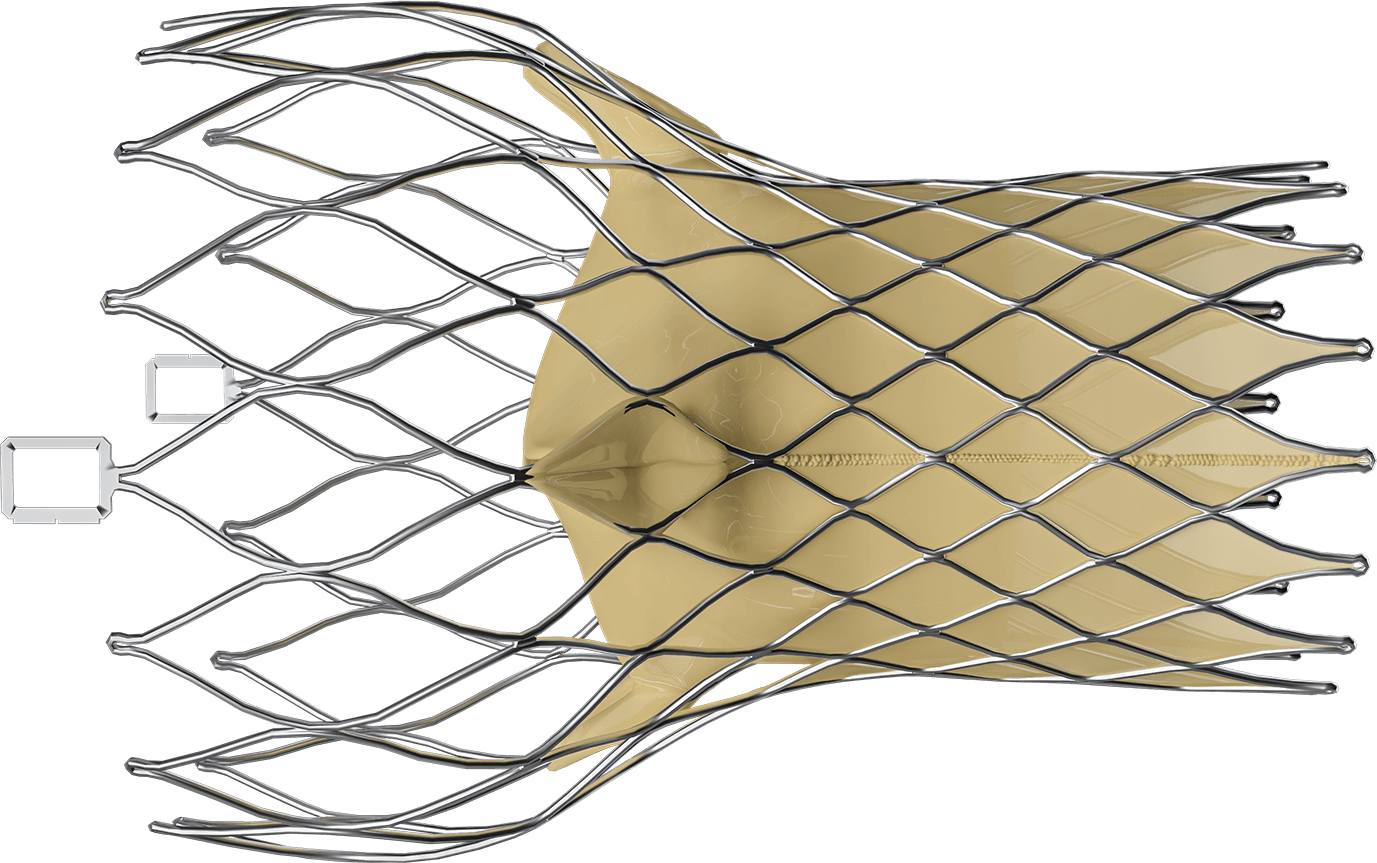

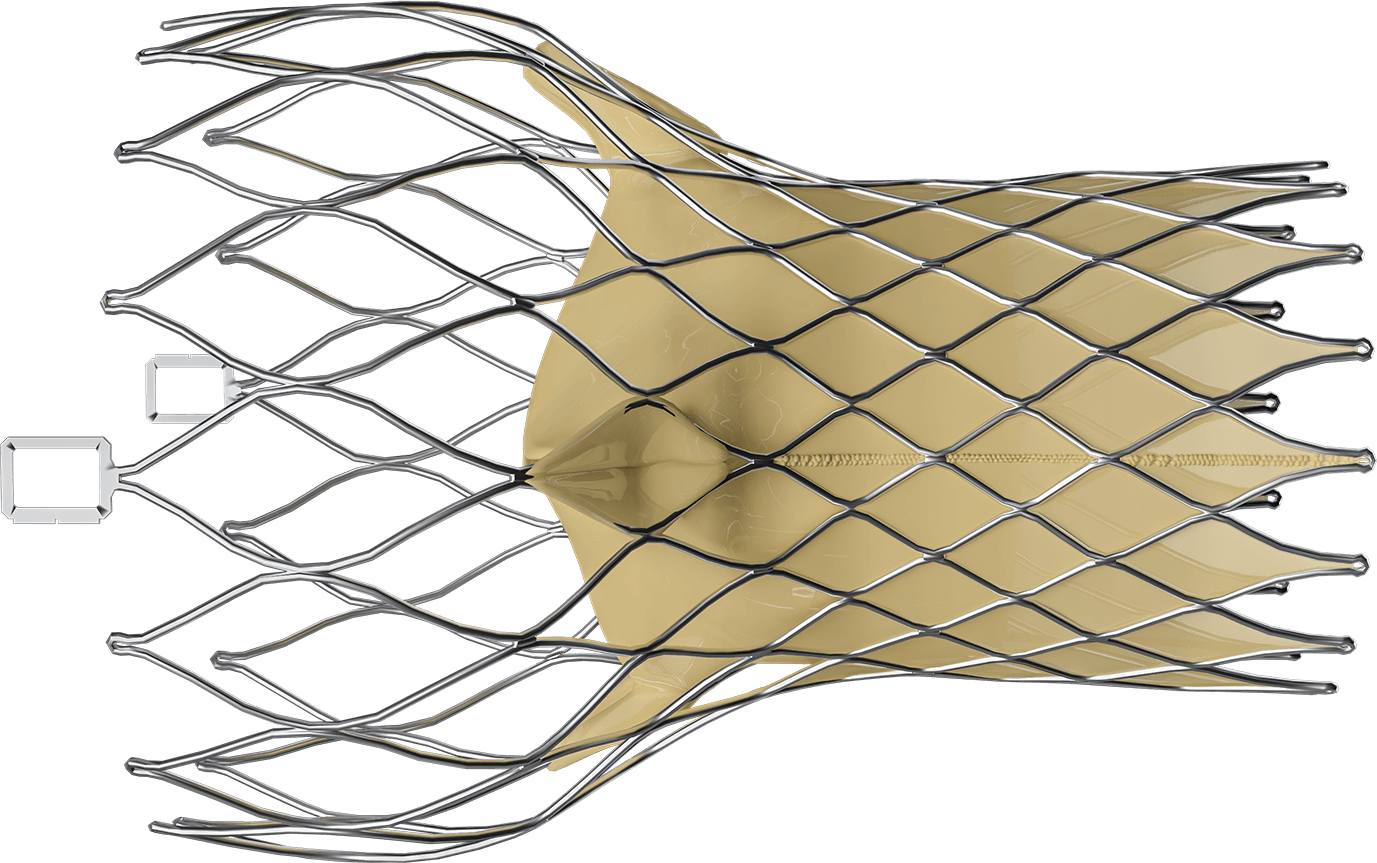

Large-scale nitinol device production

Nitinol is widely used in medical devices due to its superior superelasticity, shape memory effect,

low stiffness, damping, biocompatibility, and

corrosion resistance. Our Nitinol AM solution empowers large-scale production of complex device geometries with pre-designed porosity, homogeneous composition, high density, and near net shape — all with little to no post-processing.

Watch the webinar

Download the white paper

Download the product sheet

Driving orthopedic AM

The next great leap in medical device production

is industrializing additive manufacturing (AM). PowderLife is a powder management solution

that makes AM possible, ensuring quality and reusability, and managing material and inventory.

Get rocking

Live the PowderLife

Download the white paper

Watch the webinar

Download the Product Sheet

Controlled residual stress bar

Conventionally produced stainless steel bar products contain randomly distributed residual stresses that lead to dimensional instability concerns and increased risk to the patient. Carpenter Technology has developed state-of-the-art automated processing that controls levels of residual stresses, delivering:

and the most intense medical challenges

Live The Powderlife

Download the white paper

Controlled residual stress bar

Conventionally produced stainless steel bar products contain randomly distributed residual stresses that lead to dimensional instability concerns and increased risk to the patient. Carpenter Technology has developed state-of-the-art automated processing that controls levels of residual stresses, delivering:

Large-scale nitinol device production

Download the white paper

Controlled residual stress bar

Conventionally produced stainless steel bar products contain randomly distributed residual stresses that lead to dimensional instability concerns and increased risk to the patient. Carpenter Technology has developed state-of-the-art automated processing that controls levels of residual stresses, delivering:

Large-scale nitinol device production

Download the Medical Titanium Brochure