Click on the tiles to learn more about the topics we are exploring.

SUSTAINABILITY GOALS

MITIGATING SUPPLY CHAIN RISKS

EXTENDING THE USEFUL LIFE OF PRODUCTS

PV MODULE RECYCLING

EV BATTERY REPURPOSING

REPURPOSING WIND TURBINE BLADES

SUSTAINABILITY GOALS

Long-term environmental and sustainability goals at the federal level are also driving a transition toward circular economies. For example, in March 2020, the European Commission released a circular economy action plan. The plan lays out strategies and policies for eliminating waste and bolstering biodiversity while also achieving Europe’s 2050 net zero carbon emissions target. In the United States, the 2021 Bipartisan Infrastructure Law allocated nearly $7 billion for new and expanded commercial-scale processing, manufacturing, and recycling facilities.

MITIGATING SUPPLY CHAIN RISKS

Pursuing circularity can also mitigate risk. For example, supply chain bottlenecks have slowed and canceled projects in recent years due to increased costs and a lack of products and materials. But what happens to those project risks when companies can take advantage of local supply chains of recycled and reused equipment and materials rather than depending on imports? One example of this approach is extending the life of transformers or refurbishing and redeploying them in new facilities. Another risk mitigation benefit is reducing dependency on foreign nations controlling critical materials. While pricing is a significant risk, so too are human rights violations. The U.S., European Union, and China have actively made significant federal investments in recycling infrastructure to extract, purify and reuse materials such as lithium, cobalt, and nickel in new lithium-ion battery manufacture.

EXTENDING THE USEFUL LIFE OF PRODUCTS

There is economic value in rethinking everything about products, from designing them to making recycling and reuse easier to extending their useful life. Understanding this value is not just about sustainability. It is also about developing new business models, such as product-as-a-service and sharing platforms that give people access to products when they need them through a subscription instead of an outright purchase.

PV MODULE RECYCLING

The first commercial recycling plants with advanced treatments to separate materials are being planned and constructed to support the growing supply of end-of-life solar modules. Innovative recycling processes being tested at a pilot scale may offer enhanced recycling quality and compete with landfill disposal prices in the future. The National Renewable Energy Laboratory (NREL) estimates that between 25 and 30 percent of all silver, aluminum, and silicon used in the solar industry could be supplied by recycled modules after 2040.

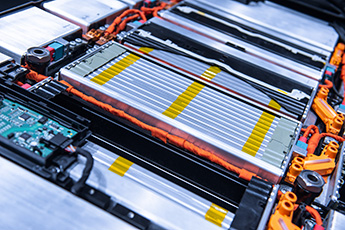

EV BATTERY REPURPOSING

As the number of EVs increases, the opportunities for battery repurposing in stationary applications multiply. According to an estimate by McKinsey & Company, the supply of EV batteries that can be used for stationary storage could surpass 200 GWh annually by 2030. This approach takes advantage of the substantial value retained by electric vehicle (EV) batteries after they are no longer suited for powering automobiles. By some estimates, used lithium-ion EV batteries retain 80 percent of their original capacity and all the embedded energy of their manufacture. With specific software controls and integration, those used EV batteries can have a second life as stationary energy storage systems. Performance testing, hazard assessments, and warranty and liability R&D are underway now to determine feasibility.

REPURPOSING WIND TURBINE BLADES

One idea being explored is repurposing glass fiber wind turbine blades for cement co-processing. After wind turbine blades are removed from service and reduced to an appropriate size, the material can be used as an alternative fuel and raw materials for producing Portland cement. This application eliminates solid waste and reduces greenhouse gases associated with cement manufacturing.