Back to home

The Age of Enterprise AI

How the company’s solutions helped Georgia-Pacific leverage artificial intelligence to get the most from its data and optimize its processes.

The adoption of artificial intelligence (AI) in the manufacturing sector continues to grow as companies aim to improve the efficiency, reliability, and sustainability of their operations. To do so effectively, they must develop—and scale—sophisticated, AI-based systems that rely on large-scale, diverse data sets and various machine learning (ML) techniques. These systems continuously monitor operations to help prevent equipment failure and other suboptimal operating conditions by raising alerts and suggesting prescriptive actions that give operators the time to plan and respond. With decades of focused innovation in manufacturing operations, Georgia-Pacific (GP) has emerged as an industry leader in the adoption of AI systems in this space.

©2023 Fortune Media IP Limited. All Rights Reserved. Use of this site constitutes acceptance of our Terms of Use and Privacy Policy (Your California Privacy Rights) | CCPA Do Not Sell My Information Fortune may receive compensation for some links to products and services on this website. Offers may be subject to change without notice. Quotes delayed at least 15 minutes. Market data provided by Interactive Data. ETF and Mutual Fund data provided by Morningstar, Inc. Dow Jones Terms & Conditions: S&P Index data is the property of Chicago Mercantile Exchange Inc. and its licensors. All rights reserved. Terms & Conditions. Powered and implemented by Interactive Data Managed Solutions. | EU Data Subject Requests

Improving efficiency, reliability, and sustainability with C3 AI

While more than 60% of the Fortune Global 500 have set formal targets for greenhouse gas

emissions reductions, most struggle to turn these ambitious commitments into concrete plans. Today, many companies are significantly off-track to achieve those targets.

Investors and other stakeholders increasingly

expect a level of transparency and rigor around plans to achieve corporate ESG targets not unlike what they expect for financial targets. The emerging

The lack of a robust, unified ESG data infrastructure also tends to frustrate sustainability teams trying to meet ESG reporting requirements and inform day-to-day decisions. ESG covers a vast array of environmental, social, and governance topics, and disclosure requirements span a fragmented landscape of software systems, such as environmental health and safety, human resources, and enterprise resource planning (ERP). Furthermore, multiple overlapping ESG reporting standards and

Facing a wide variety of ESG issues and often limited internal resources, corporate sustainability teams find it challenging to keep track of the evolving concerns of internal and external stakeholders. Unable to tackle every ESG issue, companies need to prioritize the areas most relevant and important—and to align these priorities with key stakeholders.

The standard materiality assessment exercise—which attempts to address this prioritization challenge—is a labor-intensive process that is inherently limited in scope and impact. ESG expectations and requirements are constantly evolving, requiring a system that can function in near real time. Performing analysis every two years, for example, won’t suffice when an enterprise needs to capture timely insights to manage ESG risks and capture opportunities.

Setting priorities in alignment with stakeholders

Predictive maintenance at GP

Note: This article was published by C3 AI and originally appeared on C3 AI.

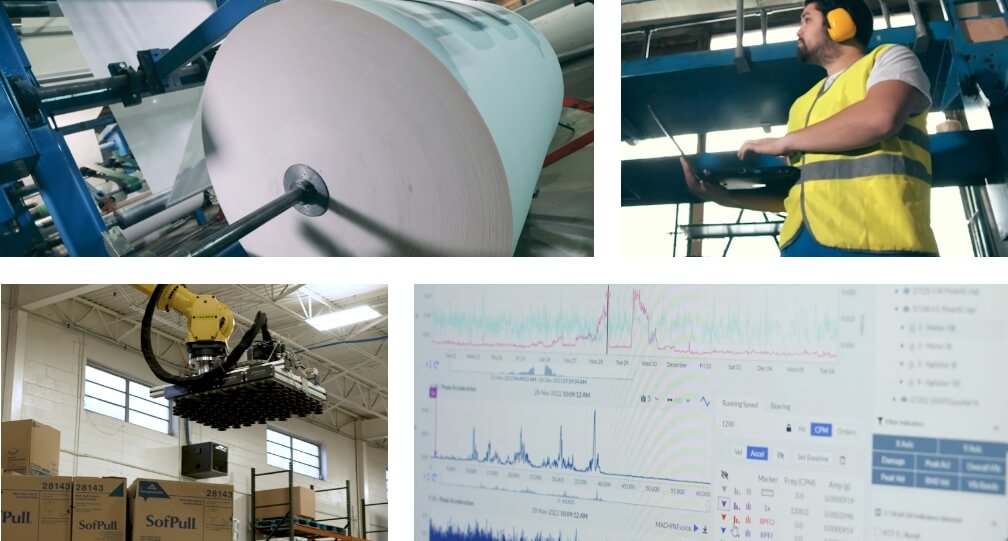

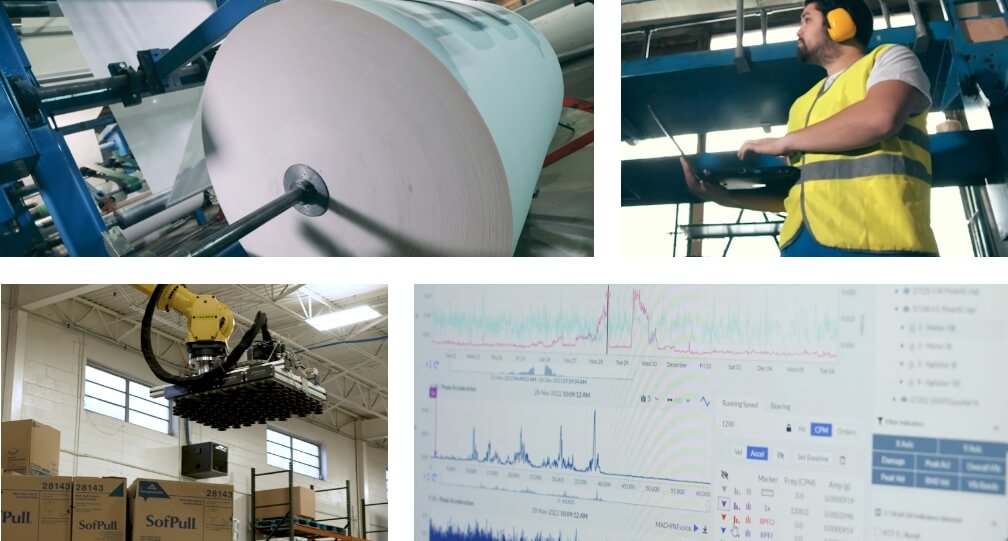

GP makes everything from the paper towels you use in your kitchen to the shipping box carrying items ordered online to the exterior panels that make up the outer sheathing of your apartment building. And as one of the world’s leading makers of tissue, pulp, packaging, and building products, GP operates more than 100 manufacturing facilities that must be optimized for production and strictly monitored and maintained.

One of these types of manufacturing facilities are paper mills. Paper mills are large-scale, complex operations—just one paper machine can be the size of a football field and eight stories tall. To run such a set of equipment to produce thousands of tons of paper daily requires extensive processes and subject matter expertise. To make paper, logs are turned into woodchips that go through various cooking, bleaching, and washing cycles, which then go into a paper machine. And to monitor the status of just one machine, a machine can easily have more than 5,000 sensors that produce billions of records of data daily.

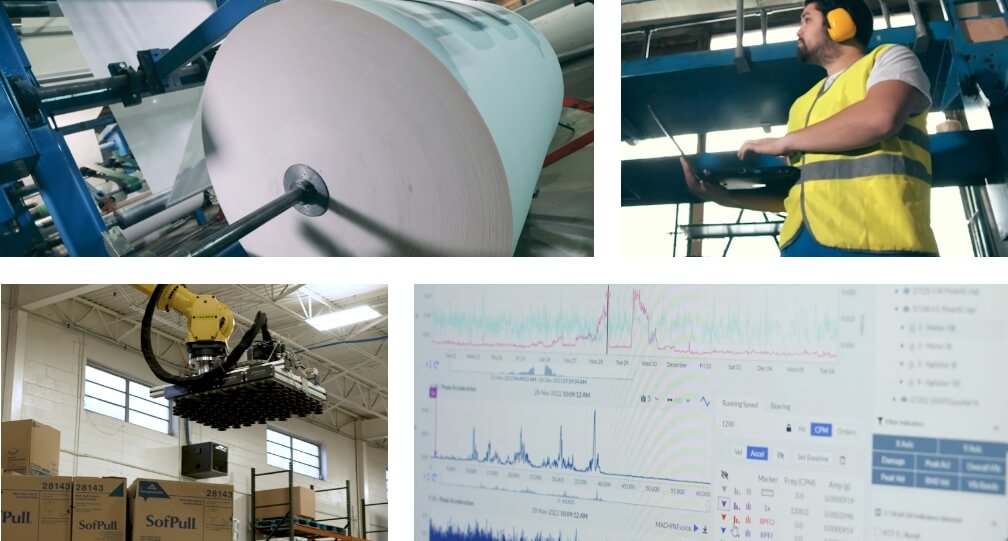

As the executive responsible for the AI and monitoring capabilities at GP manufacturing operations, Roshan Shah understands how powerful and valuable developing an effective AI program can be for business. Shah is vice president of operations at the Collaboration and Support Center (CSC) Operations at Georgia-Pacific, a unit home to more than 150 engineers, IT personnel, and data scientists whose goal is to help facilities improve efficiency and productivity.

Since it was established in 2018, the CSC has successfully reduced unplanned downtime by thousands of hours. Combining the feedback of more than 500,000 sensors that generate a new data point at least once a minute—and sometimes every second—meant developing massive digital infrastructure to not only properly transfer and maintain the data, but to also support powerful enough applications to analyze data in real time. According to Shah, around 1 trillion records need to travel to different ML models every day.

“We look at all that data that gets generated, and we leverage artificial intelligence to figure out what those sensors are telling us,” says Shah. “More often than not, they’re informing us about optimal [or suboptimal] manufacturing conditions.”

Then, the team at the CSC works with colleagues in manufacturing operations located off-site in various mills and facilities to chart the best path forward together—all with the goals of achieving the most optimal manufacturing conditions, maximizing the lives of their critical assets (e.g., boilers, pumps, tubines, etc.), and doing so in a sustainable and environmentally conscious manner.

Such short-term solutions, common when companies get in a bind, tend to neglect the underlying issue or issues, which remain hidden beneath layers of intricate data. Company executives, and the team assembled to hunt for the cause of the problem, were perplexed and frustrated, especially given the rigorous planning that goes into warehouse space requirements to prepare for the peak sales season.

The team dug in, asking logical questions: Were products not selling? If so, which ones? If so, why not? Further, why aren’t our systems (and people) aware of the falloff in demand? Did we do a bad job forecasting demand and simply buy too much? Or is the problem technical, where the information transmitted about capacity or order churn is incorrect? If so, why? And on and on.

Warehouse analysts looked at data trends on warehouse management systems (WMS), searching for clues across inventory levels. Eventually, the inventory managers on the team discovered unusual patterns that revealed a sluggish turnover of tennis shoes. Demand for tennis shoes was stable, however, so the excess inventory wasn’t caused by a slowdown in sales.

The team kept probing. Through work with the demand planners, the group discovered considerable fluctuation in lead times by a key supplier of tennis shoes. Deeper analysis showed that this supplier had recently relocated its manufacturing operations from Mexico to East Asia, resulting in erratic lead times as the supplier adapted to the new geography and was ramping its logistics and manufacturing capabilities.

At last, puzzle solved. The variability in lead times triggered what’s known as the bullwhip effect, a phenomenon that describes increasingly large swings in inventory levels triggered by small changes in demand or orders from suppliers. This led inventory managers to stockpile inventory as a buffer against fluctuating lead times and supply variabilities. That, in turn, only made the inventory problem worse.

As a solution, the company immediately began looking for alternative sources for tennis shoes while the primary supplier stabilized its operations.

This all took many long days of analysis and data hunting. Along the way, experts from elsewhere in the company were pulled in as needed, including category planners and forecasting specialists. Data extraction from various systems—including WMS, order management, inventory management, supplier contracts, procurement, and transportation—posed a considerable challenge since these systems used different software platforms, such as SAP,

Oracle, and specialized software for specific functions. The complexity made data retrieval a daunting task; moreover, critical information was buried within unstructured data sources, such as PDF documents and HTML pages.

Ultimately, getting to the root cause of the issue took a very busy three months, with help from people far beyond the core team of 30 or so assembled to attack the problem.

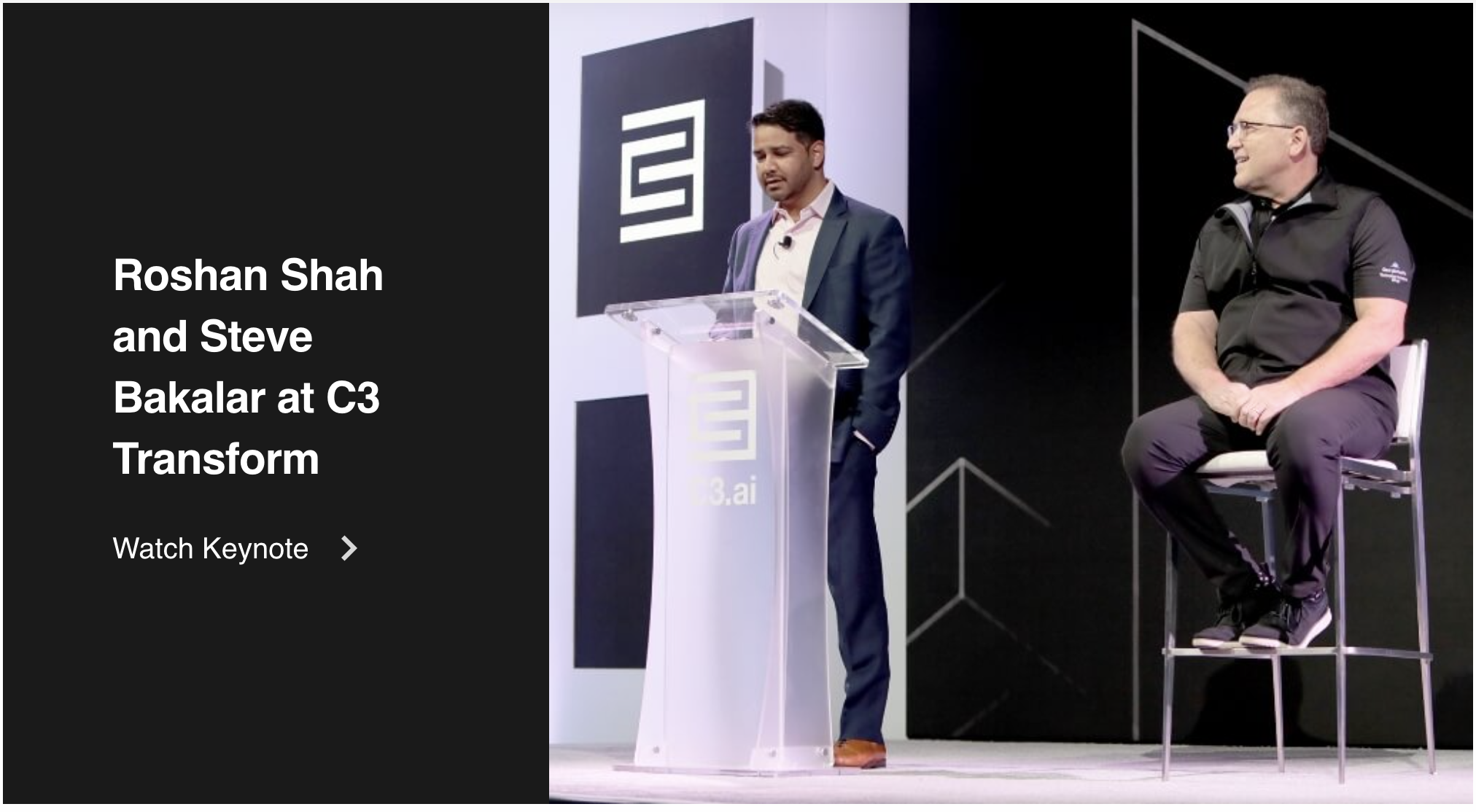

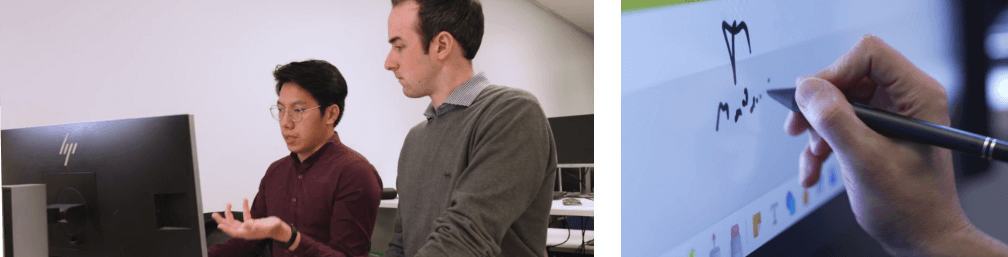

“C3 AI has been unique in more than one way,” says Shah. “The first thing that I would share is the ability to take data from many different places and combine them into one has been really phenomenal. Second, when we think about the reusability component, that’s been pretty big. And the third one actually goes even further down. It’s the artificial intelligence models themselves. The C3 AI Type System has been incredibly powerful, and it really helps us develop use cases much faster.”

Here, Shah is talking about how C3 AI’s technology is built to rapidly deploy into complex environments, using a unique model-driven architecture. This architecture provides a way to use data from many different sources without having to extract, standardize, and reload all your data onto one system—C3 AI’s applications work with customers’ existing software systems.

A major benefit of this system is the reusability of C3 AI’s models. Once engineers have developed and optimized a model that say, predicts when a certain part needs to be replaced, that model can be replicated and reused to predict something completely different. This significantly lowers development time for teams and accelerates the deployment timeline—and consequently, the time to value.

And although using the C3 AI Type System is an entirely new way of working, the team at the CSC has been able to take full advantage of its benefits after C3 AI onboarding training, which is always built into any project at C3 AI. After the team was able to get up to speed, Coyne says it hit its stride, and it’s now natural—and more efficient—for them to work with it.

What’s next

How the company’s solutions helped Georgia-Pacific leverage artificial intelligence to get the most from its data and optimize its processes.

Improving efficiency, reliability, and sustainability with C3 AI

The Age of Enterprise AI

Back to home

©2023 Fortune Media IP Limited. All Rights Reserved. Use of this site constitutes acceptance of our Terms of Use and Privacy Policy (Your California Privacy Rights) | CCPA Do Not Sell My Information Fortune may receive compensation for some links to products and services on this website. Offers may be subject to change without notice. Quotes delayed at least 15 minutes. Market data provided by Interactive Data. ETF and Mutual Fund data provided by Morningstar, Inc. Dow Jones Terms & Conditions: S&P Index data is the property of Chicago Mercantile Exchange Inc. and its licensors. All rights reserved. Terms & Conditions. Powered and implemented by Interactive Data Managed Solutions. | EU Data Subject Requests

Transforming the future of enterprise software with generative AI

How generative AI enables enterprise intelligence

Transforming enterprise data operations with generative AI

EXPLORE MORE

The evolution of supply chains in the past couple of decades is astory of technological advances: logistics software that tracks itemsin near-real-time; sensors everywhere, via the internet of things(IoT), that make that tracking possible, feeding data into supplychain management systems; the rise of cloud and edge computing;ever-improving connectivity (think 5G) to link it all; and enterpriseAI applications to optimize scheduling, predict risks, and forecastdemand.

Note: This article was created and published by C3 AI.

From my seat on the bus, not doing digital transformation is not an option. As a

manufacturing firm, we have to jump on the ability to be able to bring information in front of folks really quickly so that they can make better decisions.”

“

—Roshan Shah Vice President, CSC Operations, Georgia-Pacific

Improving and accelerating with C3 AI

“We’re attempting to take the skills and knowledge of our experienced folks, of our machines, and combine all of that such that we can empower the new generation of our colleagues to be able to make better decisions really fast,” says Shah. “The goal of digital transformation is to make it so a three-year employee can operate as if they had about 20 years’ worth of experience.”

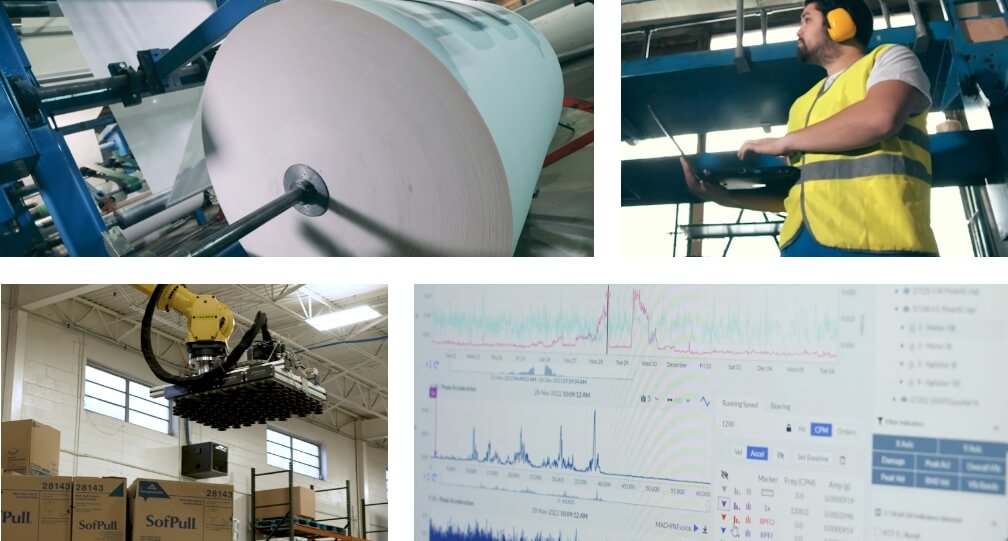

Initially, the CSC implemented analytical models that monitored individual sensor readings, known as tags, which is an effective approach for simple assets. However, as the CSC scaled up its program to monitor more complex assets, it found that its existing software platforms weren’t optimized to meet both modeling and data integration needs; it needed a new solution that could monitor asset health at an asset level (versus tag-level), utilize a large amount of data from disparate sources in a single model, and deploy and operationalize advanced ML techniques to improve monitoring performance of all assets—this is where C3 AI entered the picture.

In 2020, GP and C3 AI began a multiyear partnership and together quickly identified a first project: deploying the C3 AI Reliability application to improve operations and reduce unplanned downtime for complex assets and other critical equipment.

GP decided to kick off the project with one asset class that is critical to the manufacturing process and downtime avoidance. The teams deployed C3 AI Reliability for a subset of these assets across facilities, which meant unifying sources of process data, vibration data, downtime indicator data, work orders, and asset hierarchies into the application. This upfront data unification laid the foundation to scale from 60 to more than 200 of these assets as well as introduce new asset classes in the application.

The process of getting the [C3 AI] Reliability platform up and running was one that fundamentally changed the way we work. With the training that C3 AI provided, we were able to unify our working process, and it wasn’t people working in silos anymore. The team was working together as one cohesive unit.”

—Sam Coyne, Director of AI, Georgia-Pacific

“

Today, GP has rolled out C3 AI Reliability to monitor more than 200 large assets across facilities and plans to expand the application’s use to monitor additional critical asset classes over the next year.

“[C3 AI Reliability] is really helping us in an intuitive sense become more predictable in how our assets are going to run, as opposed to having to react in an unfavorable manner, and it’s helping us operate in a much better state,” says Shah. “And it certainly has had an impact on our bottom line in a favorable way.”

With the combination of more data, contextualized sensor readings, and advanced ML techniques, GP is seeing up to 5% improvement in overall equipment effectiveness (OEE) from its C3 AI Reliability deployment. With the continued initial success, GP plans to expand the scope of C3 AI Reliability to eight additional asset classes in the next year.

When the team knows when, why, and how an asset will fail, the members can plan ahead to purchase the right parts at the best price and schedule work orders at the best time for their employees.

“What we’re also able to do is empower our colleagues to spend 80% of their time addressing the problems as opposed to looking for them,” Shah says. “AI helps us improve the lives of our colleagues and the communities that we operate in because this means reducing the risk of an unplanned event in an unfavorable environment. That’s been quite rewarding and fulfilling for us.”

Learn how C3 AI Reliability can help your organization in a personalized demo. Schedule a briefing here.

Since it was established in 2018, the CSC has successfully reduced unplanned downtime by thousands of hours. Combining the feedback of more than 500,000 sensors that generate a new data point at least once a minute—and sometimes every second—meant developing massive digital infrastructure to not only properly transfer and maintain the data, but to also support powerful enough applications to analyze data in real time. According to Shah, around 1 trillion records need to travel to different ML models every day.

“We look at all that data that gets generated, and we leverage artificial intelligence to figure out what those sensors are telling us,” says Shah. “More often than not, they’re informing us about optimal [or suboptimal] manufacturing conditions.”

Then, the team at the CSC works with colleagues in manufacturing operations located off-site in various mills and facilities to chart the best path forward together—all with the goals of achieving the most optimal manufacturing conditions, maximizing the lives of their critical assets (e.g., boilers, pumps, tubines, etc.), and doing so in a sustainable and environmentally conscious manner.

Predictive maintenance at GP

From my seat on the bus, not doing digital transformation is not an option. As a manufacturing firm, we have to jump on the ability to be able to bring information in front of folks really quickly so that they can make better decisions.”

—Sam Coyne, Director of AI, Georgia-Pacific

“

Roshan Shah and Steve Bakalar at C3 Transform

Watch Keynote

“We’re attempting to take the skills and knowledge of our experienced folks, of our machines, and combine all of that such that we can empower the new generation of our colleagues to be able to make better decisions really fast,” says Shah. “The goal of digital transformation is to make it so a three-year employee can operate as if they had about 20 years’ worth of experience.”

Improving and accelerating with C3 AI