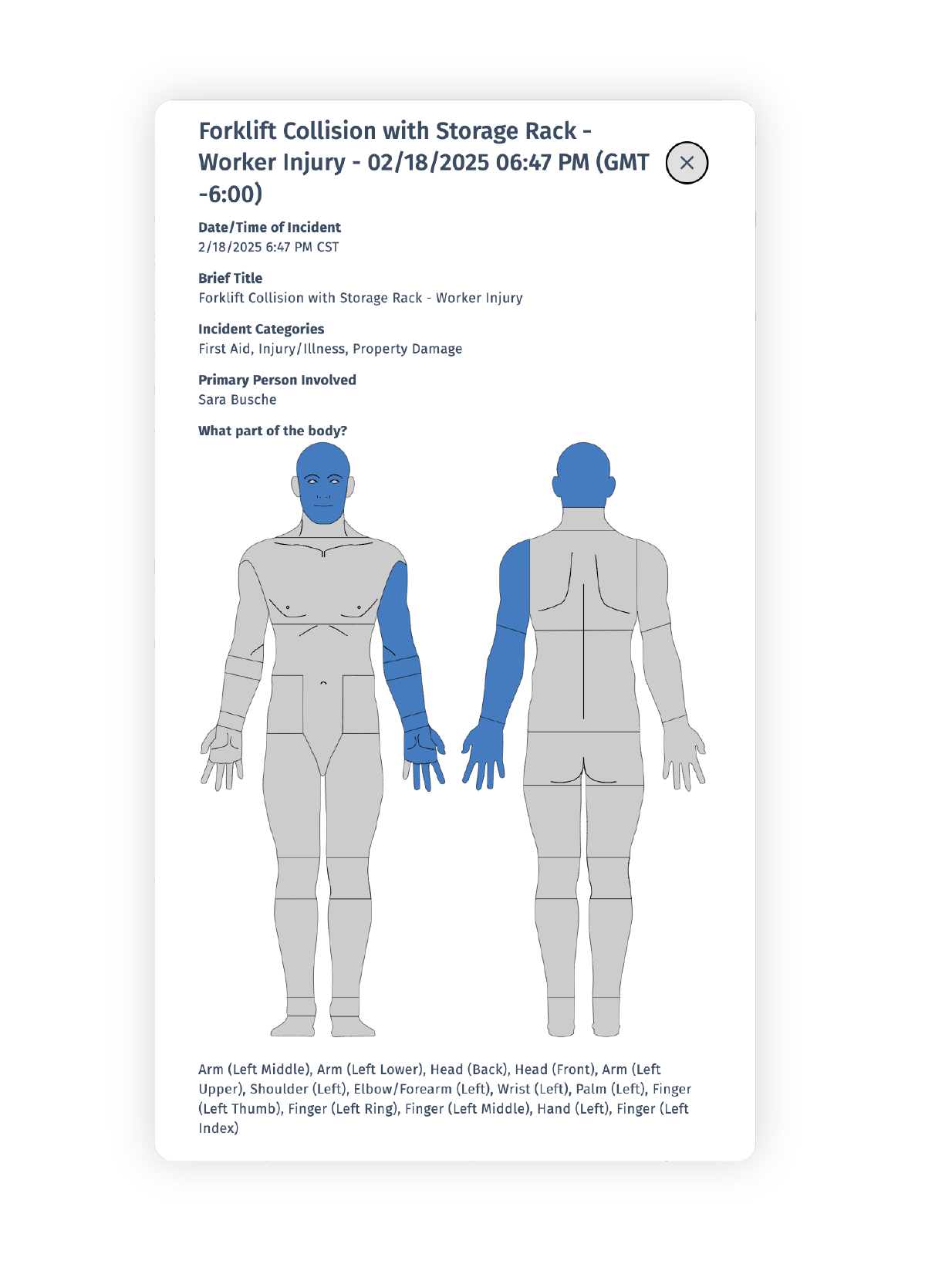

A Connected Approach to Incident Management

At a jobsite, a forklift operator backs into a storage

rack, causing pallets to fall and fracture a worker’s

arm. How would this event play out on your site?

For companies with a comprehensive EHS program,

it triggers a full-scale, intelligent response process.

Discover how incidents are managed seamlessly

from start to finish when an intelligent platform

connects every aspect of workplace safety.

How AI Enhances EHS

Comprehensive EHS Makes a Real Impact

Leveraging AI in your EHS processes makes safety and

compliance more intelligent. It shifts your approach

from manual tasks to a smarter, proactive strategy. It

helps identify hazards, eliminate human bias, uncover

patterns, and provide recommendations to minimize

incidents, transforming your workplace into a safer,

more efficient environment.

Take our EHS Assessment to see how an intelligent system can benefit your team.

TAKE ASSESSMENT

Of EHS leaders are at risk due

to point solutions that impact

response time and compliance

Of EHS programs are at risk due

to siloed incident reporting

Increase in operational

productivity in year one with

an integrated EHS system

Reduction in TRIR on average

with EHS software

70%

52%

76%

76%

Now that we have this treasure trove

of information from all our projects,

we can process that data in real-time,

identify our problem areas, and

proactively put our focus on the

highest risks before incidents happen.

”

Pimmie Aendenboom

QHSE Manager, BESIX

TRANSFORMING WORKPLACE SAFETY:

Only 5% of companies have all their EHS processes in a single management system

5%

Dashboard

Actionable leading and lagging

indicators support proactive safety

Up-to-date insights on incidents,

compliance, and risk empower

faster decision-making

All data flows into a central

dashboard to create a single

source of truth

05

Actionable Dashboard & Reporting

Robust safety training can reduce workplace injuries by up to 50%

50%

Incident Review

Automated follow-up inspections are

scheduled to verify corrections

Incident data feeds AI-driven training

paths to prevent similar accidents

Relevant procedures are uploaded to

support the discussion

Incidents are automatically flagged for

review during the next Toolbox Talk

04

Safety Training & Improved Process

EHS system can save companies an average of 12-15 hours per week per manager

12-15 Hrs

Data Logging

Track equipment failures and

corrective actions, staying compliant

with OSHA standards

Schedule and track repairs, ensuring

timely fixes and minimized disruptions

Review maintenance history to

identify past issues and prevent

recurring problems

Log forklift and storage rack damage

for quick insights, reducing downtime

03

Complete Asset Management

Automated corrective actions lead to a 40% drop in repeat incidents

40%

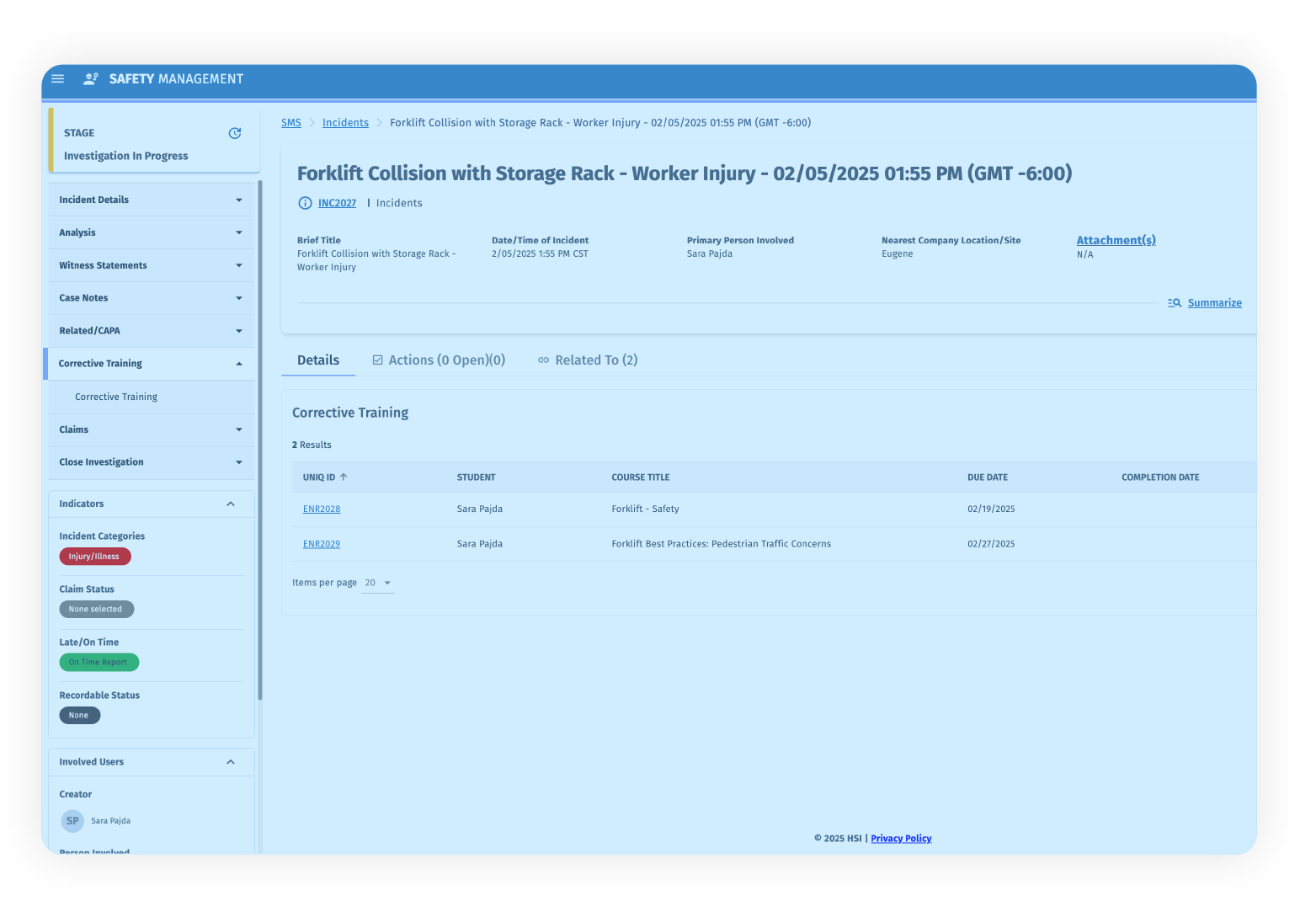

Incident Details

Full-circle corrective action ensures

immediate resolution as well as

long-term prevention

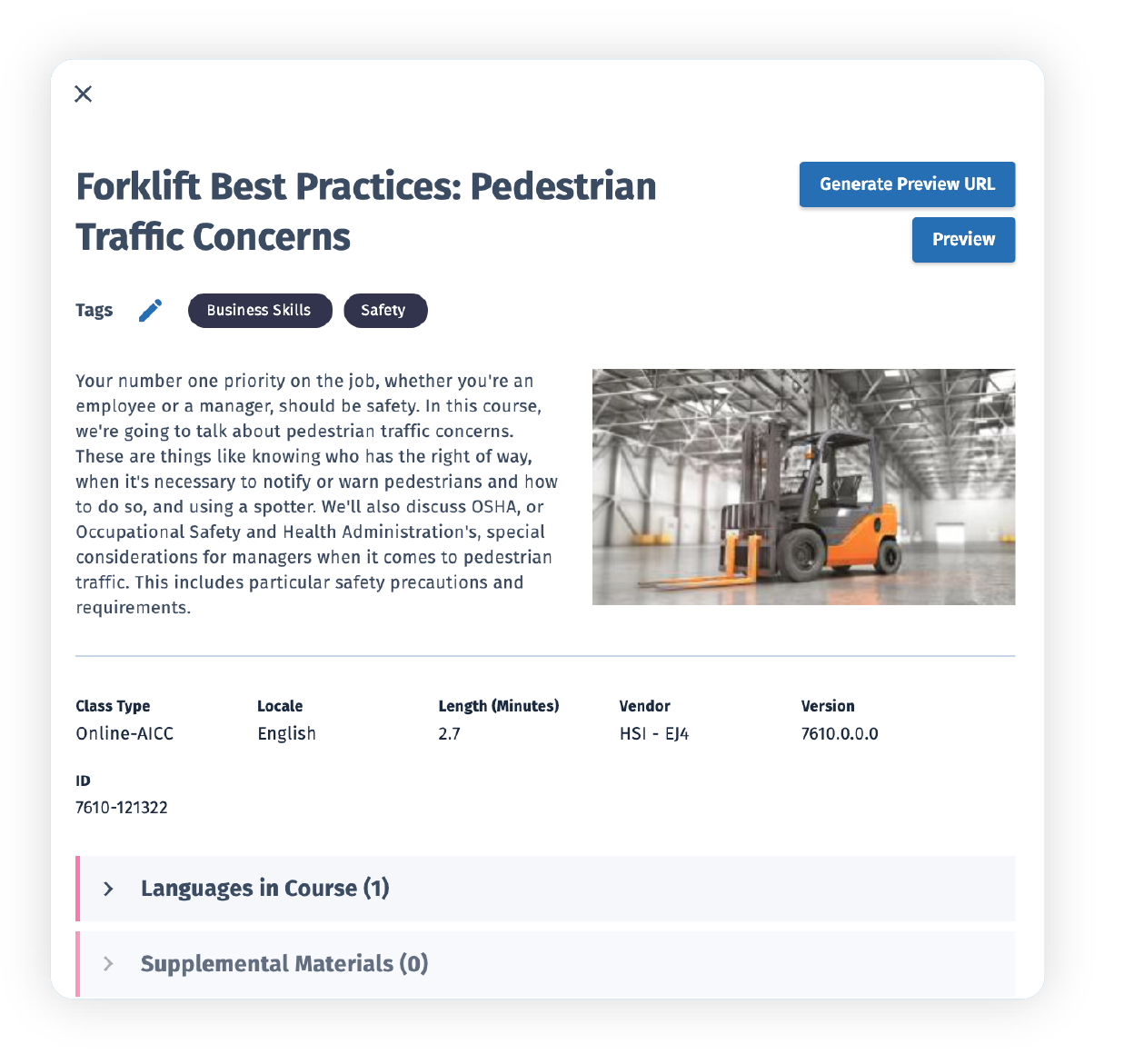

Training paths are generated,

enhanced by AI and linked to

employee records

AI-suggested corrective actions

are automatically assigned,

tracked, and linked

02

Full-Circle Corrective Action

Reduction in incident resolution times

30%

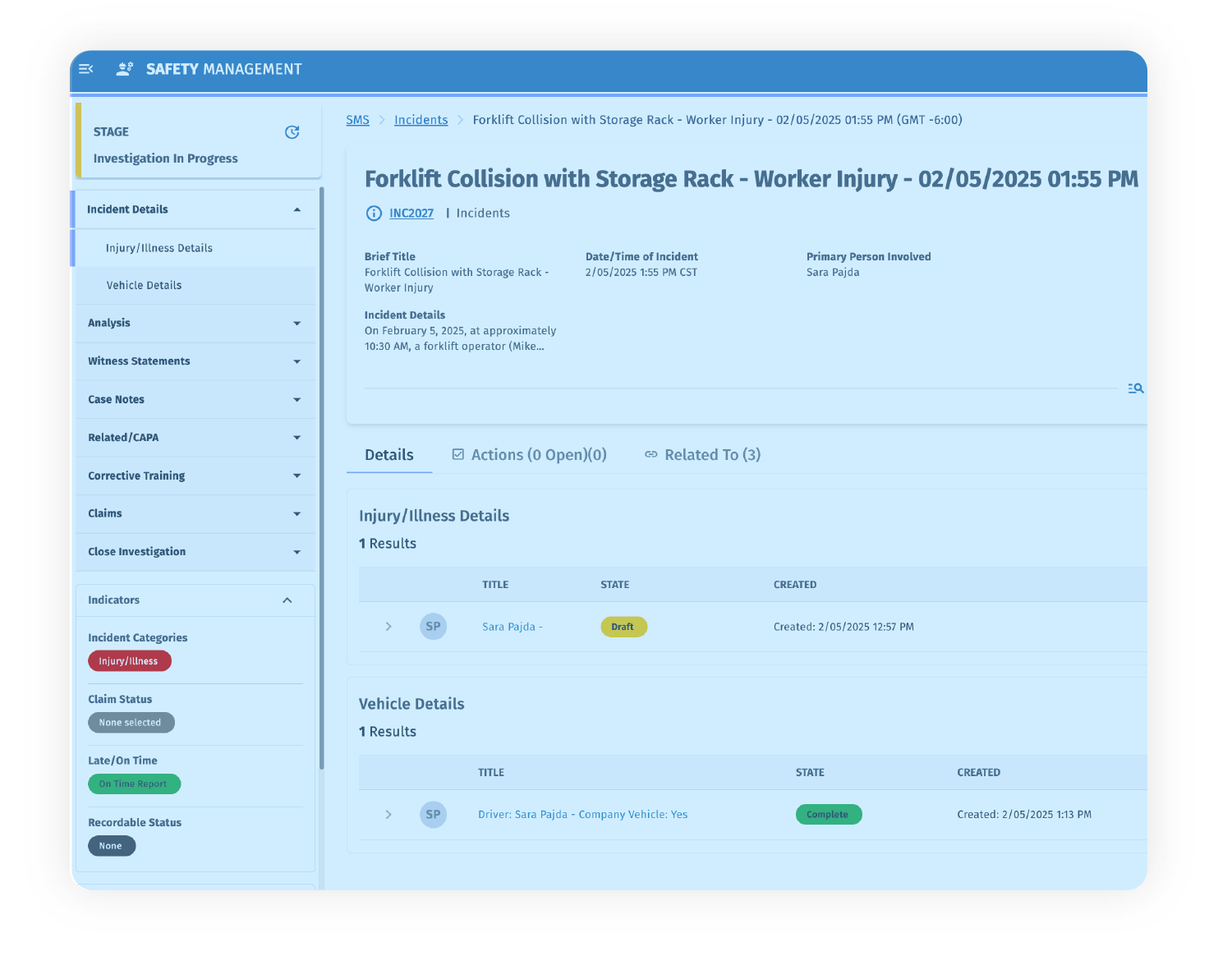

Incident Details

Automated workflows connect all

steps, ensuring seamless tracking

through to resolution

OSHA 301 and 300A forms are

auto-populated

Automated workflows connect all

steps, ensuring seamless tracking

through to resolution

Automated notifications with AI-driven

summaries alert professionals

immediately

OSHA 301 and 300A forms are

auto-populated

Automated workflows connect all

steps, ensuring seamless tracking

through to resolution

Investigation starts immediately as

data triggers an on-the-spot evaluation

01

Digital Incident Management

5 Elements of Intelligent Incident Management

Incident Scenario