ADEPT TM technology - Ammonia cracking: Licensed technology and catalysts

Get in touch

Flexible, efficient ammonia cracking technology

Why choose JM for ammonia cracking?

Are you thinking about Ammonia Cracking? Our experts are ready to support you every step of the way. Let's discuss how we can help.

Send a message

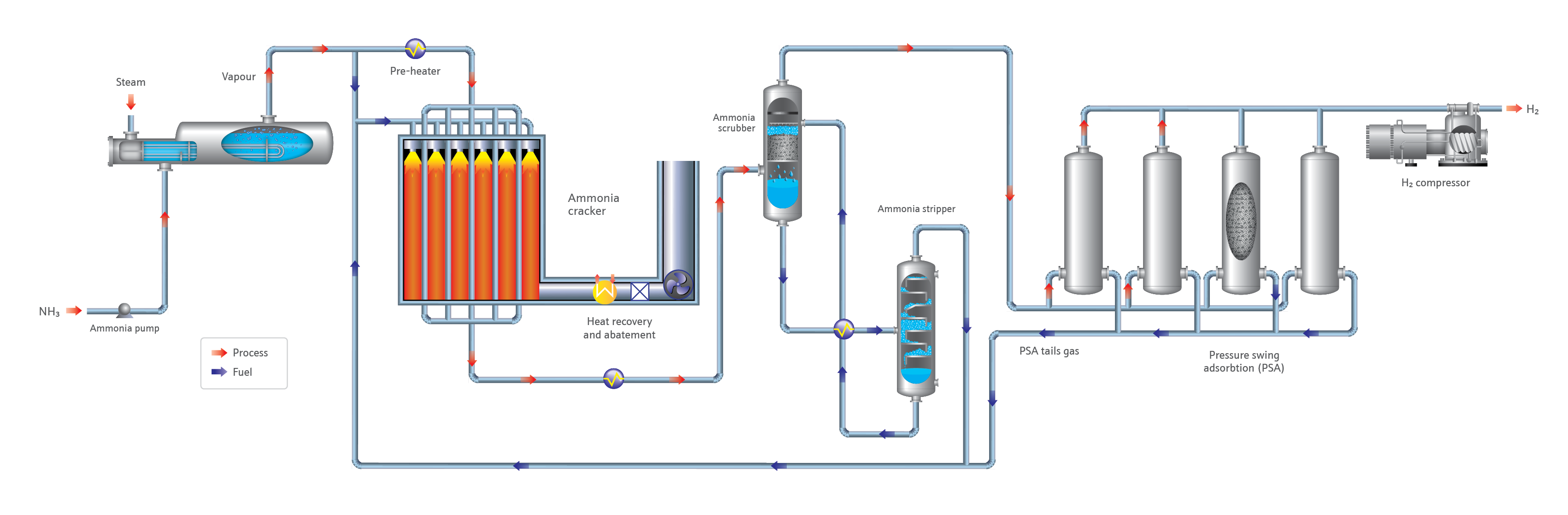

Our ammonia cracking process uses JM’s expertise in steam methane reforming (SMR) technology and ammonia catalysis to deliver:

Futureproofed flowsheet concepts: Seamlessly switch between natural gas and ammonia firing.

Low carbon intensity: Achieved through our ammonia firing solution.

Flexible performance: Plants that can operate at the desired turndown.

High efficiency: Low ammonia consumption, with process guarantees.

Established catalyst: KATALCO ammonia cracking catalysts have a 50-year track record.

Get in touch

Johnson Matthey's Ammonia team

KATALCO™ 27-2 - High-temperature ammonia cracking catalysts for centralised units

A nickel-based ammonia cracking catalyst that has been used in ammonia cracking applications for over 50 years. A highly active catalyst that typically operating 650 - 950°C, giving high hydrogen yields due to low residual ammonia levels at this temperature range.

Decarbonising shipping and aviation industries

Powering the next era of flight with eSAF

At the forefront of sustainable aviation, HyCOgen™ represents Johnson Matthey's Reverse Water Gas Shift (RWGS) technology. This process, combined with FT CANS™, converts CO₂ and renewable hydrogen into SAF, enhancing supply and production efficiency while promoting feedstock flexibility..

Learn more about our eMERALD™ CO2 to methanol technology

Charting a cleaner course with eMethanol

Johnson Matthey has been commercialising its eMethanol technology since 2011. Our eMERALD™ technology converts captured CO₂ into methanol, a versatile chemical feedstock and crucial fuel for the shipping industry. Delivering up to a 143% reduction in carbon emissions, eMERALD allows you to make eMethanol for longer with fewer interruptions, lower costs, and greater reliability.

Learn more about our eMERALD™ CO2 to methanol technology

CO₂

Green H₂

Green H₂ purification

Electrolyser

Carbon capture

eSNG

eMethanol

eSAF

Methanol to jet**

JM eFuel technologies

*

**

eMERALD™ CO₂ to methanol technology

FT CANS™ technology*

DAVY ePowerGas™ technology

FT CANS™ technology is developed in collaboration with bp

Methanol to jet is an integrated solution with Honeywell UOP

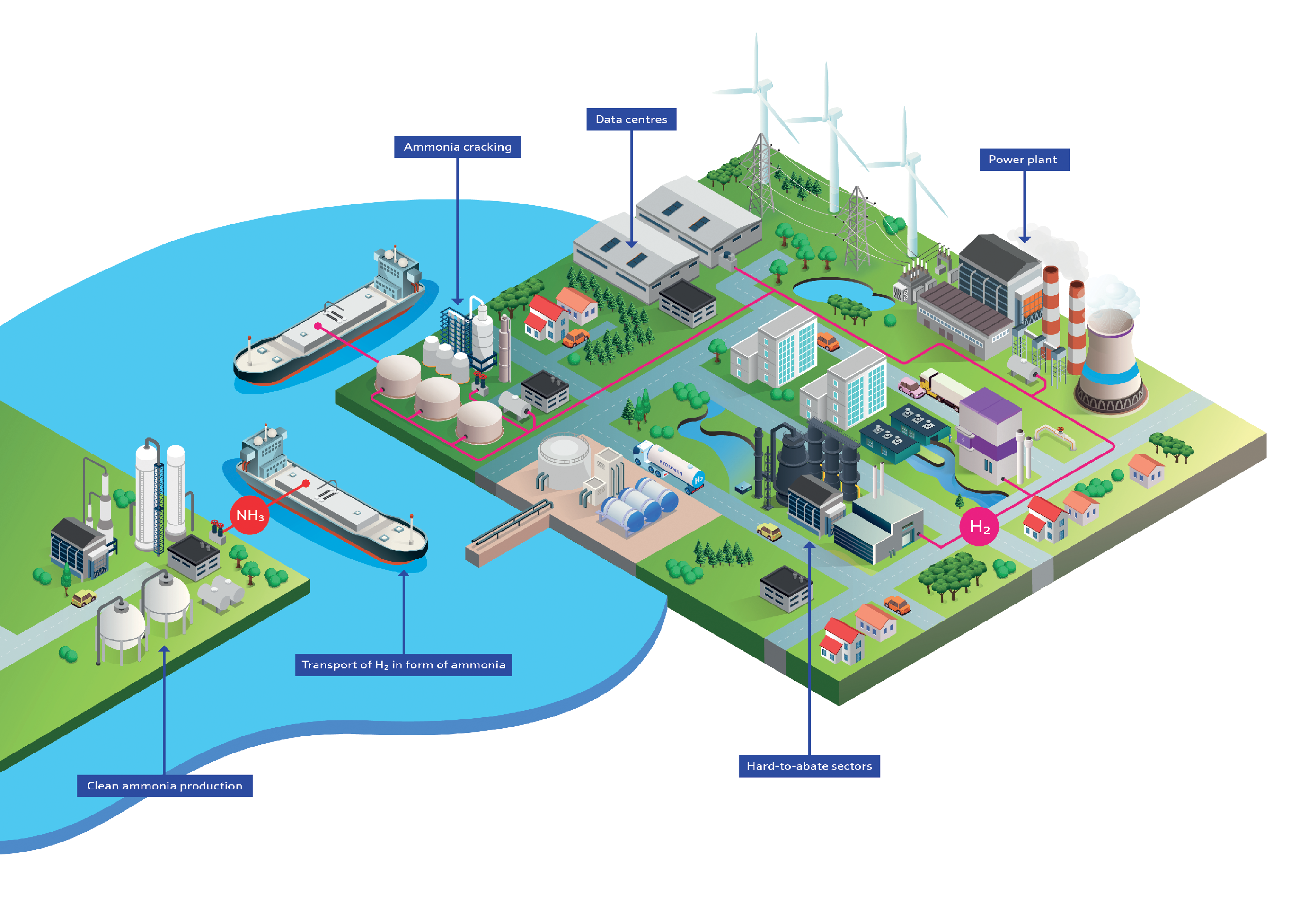

At Johnson Matthey, we understand the urgent need to reduce global greenhouse gas emissions and achieve climate neutrality by 2050. Meeting this goal will require a robust supply chain of up to 400 million tonnes of clean hydrogen and its derivatives. Ammonia offers a compelling solution as a hydrogen carrier, particularly for long-distance transport, thanks to its high hydrogen density and existing infrastructure.

However, to unlock ammonia’s full potential, it must be efficiently and economically “cracked” into hydrogen and nitrogen. This is where ammonia cracking plays a vital role in delivering clean hydrogen technology for the future.

As a leading ammonia cracking licensor, Johnson Matthey is proud to play a key role in the decarbonisation of both blue ammonia and green ammonia value chains. With advanced catalysts and licensed ADEPTTM ammonia cracking technology, we’re driving progress towards a low-carbon economy.

Partner with us to confidently drive real progress towards a more sustainable future, as we advance clean ammonia and hydrogen solutions and support the global shift towards a low-carbon economy.

Ammonia cracking’s role in low-carbon hydrogen production

High-performance ammonia cracking catalysts

KATALCO™ 27-200MQ – High-temperature ammonia cracking catalysts for centralised units

A nickel-based ammonia cracking catalyst that leverages the proven chemistry of KATALCO 27-2 and applies the benefits of improved heat transfer of Johnson Matthey’s QUADRALOBE™ shape to the ammonia cracking reaction. This high geometric surface area catalyst typically operates in the range 650 – 950°C and benefits from enhanced heat transfer performance to maximise process efficiency.

KATALCO™ 27-612 - Low temperature ammonia cracking catalysts for decentralised units

A ruthenium-based ammonia cracking catalyst developed for low temperature ammonia cracking. This catalyst typically operates in the range 400 – 500°C, substantially extending the available operating range for ammonia cracking applications. The overall economics of a low temperature application will be a balance between the savings from a lower temperature operation and the increased catalyst costs of ruthenium.

Read more

Johnson Matthey and Doosan Enerbility jointly develop integrated ammonia cracking for power plants

News

Explore

Peer-reviewed journal

Centralised and Localised Hydrogen Generation by Ammonia Decomposition:

A technical review of the ammonia cracking process

Explore

Trusted ammonia cracking licensor: 50+ years of supplying ammonia cracking catalysts along with 100-year heritage in steam reforming

End-to-end support: From catalysts to licensed technology and technical service support from our experts in the field.

Future-ready: Designed for flexible operating including desirable turndowns and seamless fuel switching.

Low carbon intensity: Achieved through our ammonia firing solution.

Get in touch

As a global provider of ammonia cracking technology and catalysts, we offer tailored solutions for both large-scale centralised cracking for the energy grid and smaller decentralised units for consumer fuel use.

Learn more about ammonia cracking and ADEPT technology