AND KENCO

A Kenco Case Study

BLUE BUFFALO

The Blue Buffalo/Kenco

In 2018, Blue Buffalo selected Kenco to run their largest distribution facility in Goodyear, AZ. This 547,000-square-foot, temperature-controlled building facilitates distribution throughout the western United States.

As Blue Buffalo opened new channels, the functions of the facility grew to match, evolving to become a multi-channel distribution center that accommodates its fast growth and new distribution channels.

Today, the Goodyear facility is responsible for distribution throughout the western US; their Direct-to-Consumer offering, Blue at Home; and the creation and fulfillment of their in-store display materials.

Relationship

Overcoming Challenges

6%

Inside the Partnership

About Blue Buffalo

Blue Buffalo creates natural, nutritious pet food for pet parents who believe "if you love them like family, you feed them like family." Blue has designed food for every stage of a pet's life using only the highest quality ingredients.

Blue Buffalo distributes their products to stores throughout the United States and direct-to-consumers through their Blue at Home offering.

In-Store�Display Creation

Blue�At Home

The facility grew from 40 to over 100 employees, operating across three shifts nearly 24/7. Despite a competitive labor market in Phoenix, AZ—where many similar facilities compete for workers—Kenco successfully scaled its workforce to meet growing demands.

Managing the�Labor Market

Managing the�Labor Market

Blue Buffalo offers specialized pet food through its direct-to-consumer (DTC) channel, Blue at Home, shipping approximately 400 orders daily across the western U.S. Integrating DTC fulfillment into a traditional distribution center presented challenges, particularly as shifting from pallet picking to each picking increased costs.

Blue�At Home

These optimizations streamlined fulfillment while maintaining Blue Buffalo’s commitment to delivering quality pet food.

In-Store�Display Creation

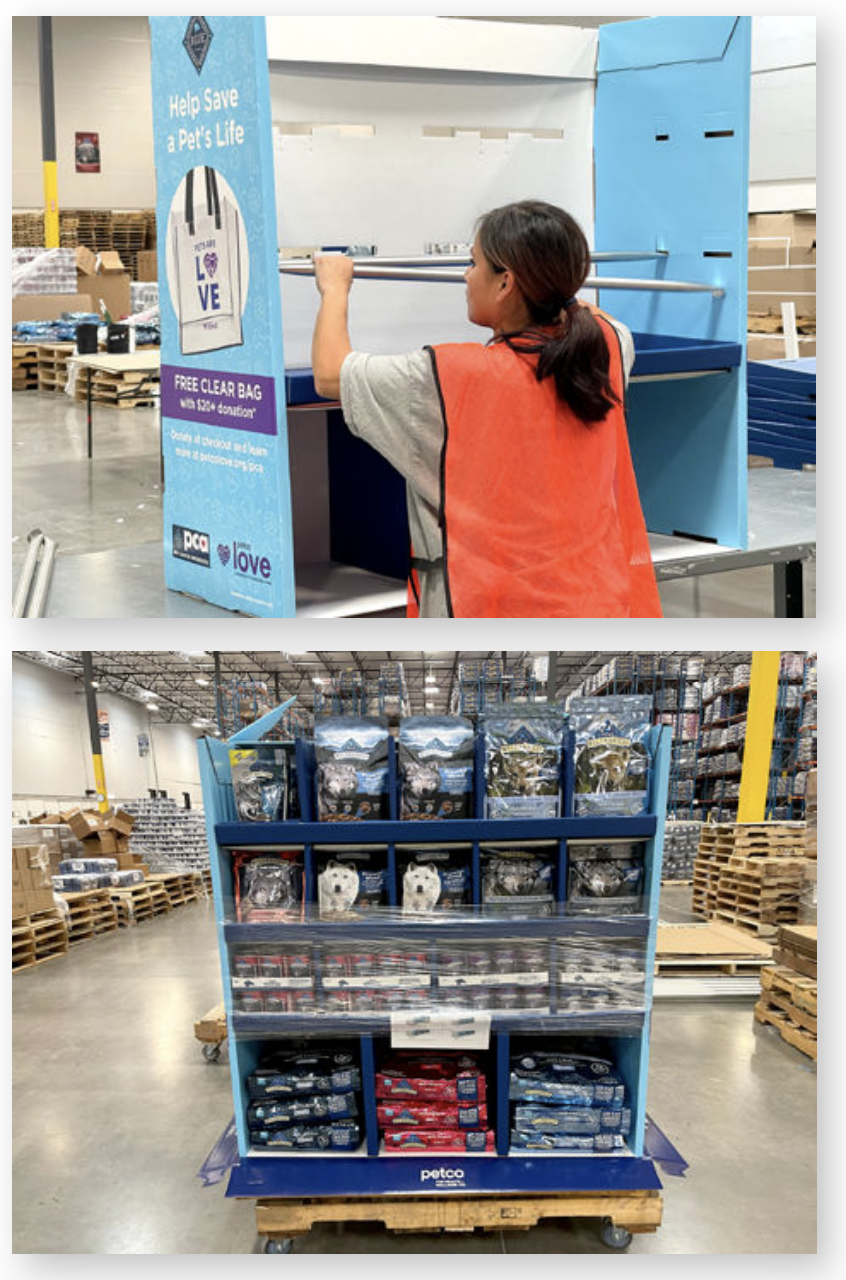

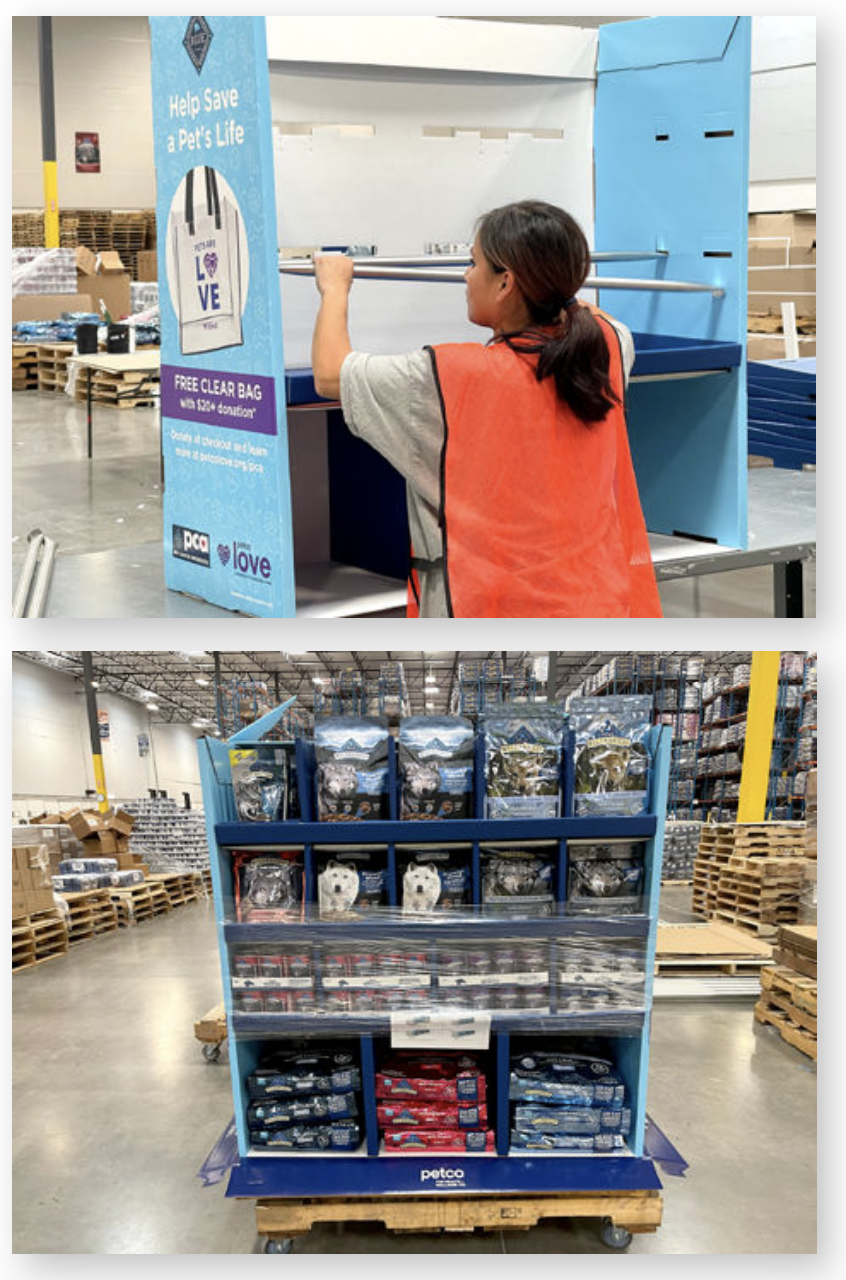

Blue Buffalo needed a partner to construct and ship in-store POP displays, a labor-intensive process requiring hands-on assembly and the ability to scale quickly during peak seasons.

Kenco implemented a streamlined process to build and ship over 75,000 displays annually, adapting to seasonal demand fluctuations.

Key solutions included:

Establishing an agile operation that scales up or down as needed

Efficiently managing labor-intensive assembly while maintaining quality

CONTACT US

CONTACT US

Let's Connect!

© 2025 Kenco Group | 2001 Riverside Drive, Chattanooga, TN | KencoGroup.com

CONTACT US

About Kenco

Kenco provides integrated logistics solutions that include distribution and fulillment, comprehensive transportation management, material handling services, and information technology—all engineered for Operational Excellence. Building lasting customer relationships for over 70 years, our focus is on common sense solutions that drive uncommon value. Visit Kenco at KencoGroup.com.

To optimize operations, Kenco organized a three-day Kaizen event, bringing together floor associates, management, and Blue Buffalo stakeholders. Participants applied Gemba principles and analyzed batching, cycle times, and order flow to identify inefficiencies.

Key improvements included:

Relocating the top 80% of ordered products to a designated warehouse area

Creating a dedicated space for efficient picking, packing, and shipping of Blue at Home orders

This approach ensures Blue Buffalo's retail displays are produced and delivered on time, even during peak demand.

By prioritizing workforce stability and employee well-being, Kenco has built a dedicated team that continues to support Blue Buffalo’s expanding operations.

To attract and retain top talent, Kenco implemented key initiatives, including:

A shift-swapping program to improve flexibility and work-life balance

Efforts to cultivate a positive workplace culture that fosters employee engagement and satisfaction

Since 2018, Blue Buffalo and Kenco have partnered to bring natural, healthy pet food to stores and homes across America.

�

The results were impressive:

Predictable

96%

Turnover Rate

Attendance Rate

100%

On-Time Shipping

ZERO

Quality Errors

ZERO

Safety Incidences

Labor and Performance Planning

CASE STUDY: distribution

To optimize operations, Kenco organized a three-day Kaizen event, bringing together floor associates, management, and Blue Buffalo stakeholders. Participants applied Gemba principles and analyzed batching, cycle times, and order flow to identify inefficiencies.

Key improvements included:

Relocating the top 80% of ordered products to a designated warehouse area

Creating a dedicated space for efficient picking, packing, and shipping of Blue at Home orders

Key improvements included:

Relocating the top 80% of ordered products to a designated warehouse area

Creating a dedicated space for efficient picking, packing, and shipping of Blue at Home orders

CONTACT US

Let's Connect!