How utilities are improving reliability with data

This Ruler is for the Space Between Text/Buttons/Callouts. Check Your Spacing for Consistency.

Electric distribution companies are using analytics and machine learning to unlock reliability gains and reduce capital spend.

Despite the influx of new technologies and smart infrastructure, the most persistent threats to reliability remain stubbornly familiar: aging infrastructure, increasingly severe weather events, demand growth and the evolving nature of the grid.

While upgrading equipment and deploying advanced sensors can certainly help, utilities don’t need to wait for full-scale modernization to make meaningful progress.

In fact, a recent audit by the Michigan Public Service Commission identified 75 specific recommendations for local utilities to improve reliability—many of which focus on better use of existing data and operational practices.

Make existing data work for you

Two of the biggest areas our clients succeed with analytics are predictive maintenance and asset management.

Connect with me

Steven Brown

Connect with me

Principal

Industry Solutions

Connect with me

Brad Boyd

VP consulting solutions

Data & AI

We have the expertise

Our Kforce Consulting Solutions teams have the industry knowledge and technical experience to help utility distributors make the most of their data.

Chat with us today to learn how foundational analytics practices can strengthen your reliability.

Contact us

Contact us

MEET THE AUTHORS

Published October 2025

Contact us

Contact us

Together Toward Tomorrow

Together Toward Tomorrow

Connect with me

“The key is not waiting for perfect data or the latest tech. You can start with what you have. We can work backward from your existing data to uncover the problems you can solve today.”

This suggests that capital investment alone isn’t enough: utilities must also optimize how they use the data they already collect.

This is where data and analytics come in. With the right approach, utilities can extract powerful insights from the data they already have without needing to invest in new infrastructure. Existing data can guide smarter, more cost-effective decisions. This includes identifying high-risk circuits, measuring the impact of vegetation management programs, improving customer-transformer ties and targeting the highest CEMI (Customers Experiencing Multiple Interruptions) impact areas.

“Despite all the changes in our industry, we still find ourselves talking about the same core issue—how to improve reliability while driving down maintenance costs,” said Steve Brown, energy and utilities industry principal for Kforce Consulting Solutions. “The key is not waiting for perfect data or the latest tech. You can start with what you have. We can work backward from your existing data to uncover the problems you can solve today.”

In this article, we’ll explore how distribution leaders can use their current data to drive real improvements in reliability.

“Advanced analytics is helping utilities turn everyday data into smarter decisions,” says Brad Boyd, data and AI practice leader for Kforce Consulting Solutions. “We’re using AI to pinpoint where reliability is at risk and where action will have the biggest impact—without waiting for new infrastructure. It’s about solving the problems that matter most, with the data you already have.”

Zippia

Applied AI in Banking: How 4 powerful use cases are driving growth

National insurance company earns major design award following Kforce UX collaboration

Preparing your organization for generative AI

Preparing your organization for generative AI

How advanced analytics and AI can save our grid from electric vehicle overload

How advanced analytics and AI can save our grid from electric vehicle overload

Success stories

benefits of migrating to a modern platform

Predictive maintenance

Preventing failure while minimizing cost requires a just-in-time approach to asset maintenance. However, we still see many utilities who are still on a calendar-based maintenance cycle.

“The most effective companies we see are planning maintenance based on device condition,” Brown said.

When available, companies use real-time sensor data. For legacy assets, utilities can use inspection data, load history and environmental data to estimate the condition of their devices on an ongoing basis.

Asset management

Knowing the right time to replace a piece of equipment can be difficult. Replacing equipment with useful life is wasteful, but running until failure degrades customer reliability.

Many utilities have taken the approach of simply replacing the oldest equipment. However, age, by itself, is not a good predicter of failure (i.e. the oldest piece of equipment is not necessarily the next to fail).

In fact, the Michigan Commission audit emphasized the importance of prioritizing equipment replacement programs “based on inspections and the actual condition of the equipment instead of solely on age of facilities.”

Understanding additional factors together—like operating conditions, inspection data and maintenance history, along with age—provides more insight into the condition of the asset. This allows utility leaders to develop a more accurate health score.

“Having a standardized scoring system allows us to then look across the grid to determine the assets most in need of repair or replacement,” Brown said. “This ensures our investment plans are aligned to deliver the best reliability for what are often scarce capital and operating and management budgets.”

Nationally, utilities are already investing heavily in infrastructure. U.S. electric utilities spent more than $50 billion in 2023 on distribution system upgrades, according to the American Society of Civil Engineers. Nearly $28 billion was also spent on transformer replacements. That number is projected to jump to $32 billion in 2026.

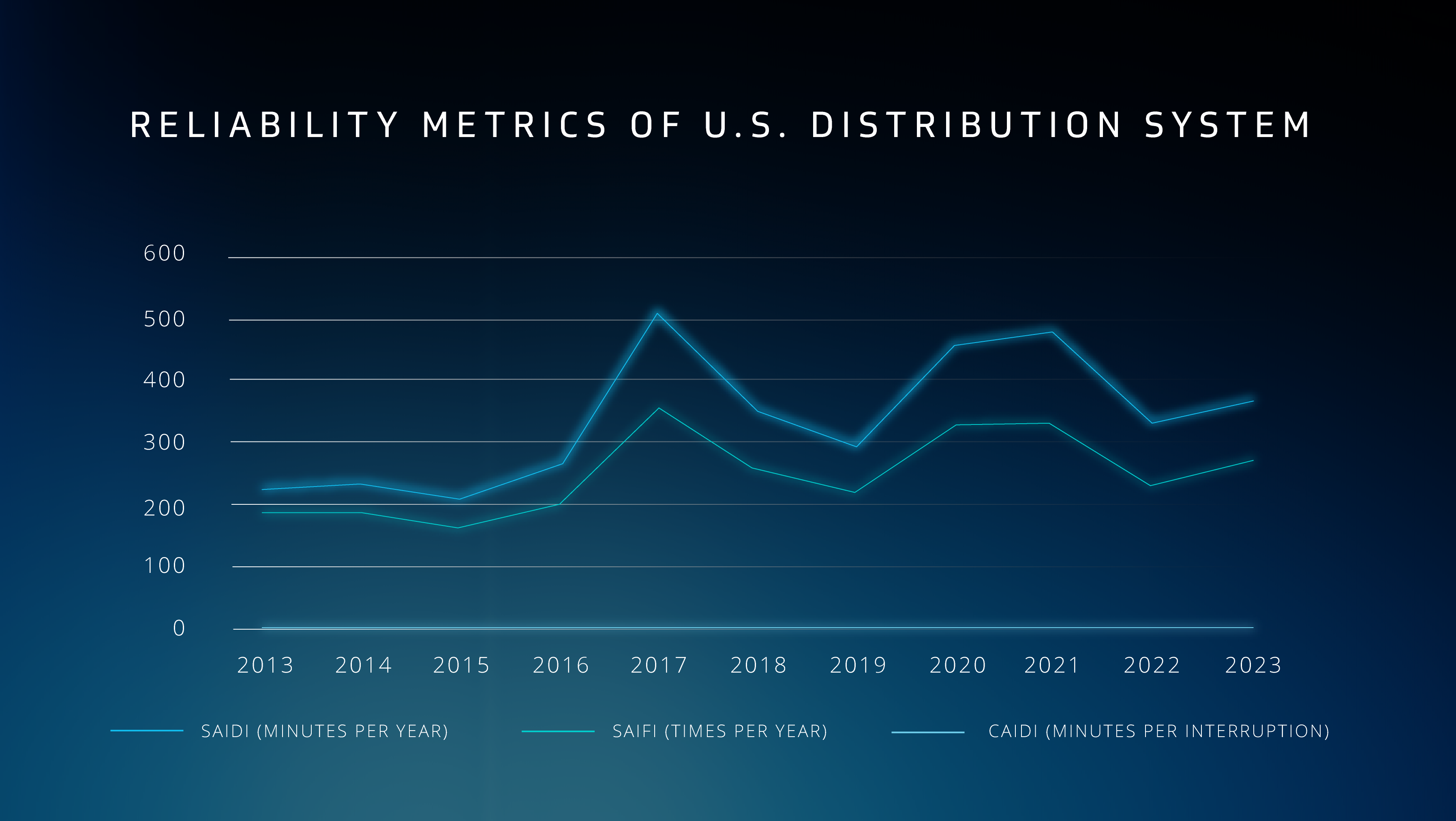

Yet, despite these investments, reliability metrics have remained relatively flat in recent years after coming down from all-time highs, according to the U.S. Energy Information Administration’s most recent annual report.

In conversations with distribution leaders, our Kforce Consulting Solutions teams often find companies get stuck on how to move forward in an environment of legacy and modern devices.

Utilities have a lot of real-time data on their newer devices but might only have inspection data on most of their legacy devices.

“We see them struggle to make sense of the disparate views of their assets,” Brown said. “In some cases, they aren’t even using the data from their newer assets because their processes are still oriented to their legacy assets.”

Leading companies are tapping into data from both their legacy and modern devices to build an integrated equipment health scoring system.

For example, the IEEE Annex PC57.91 G Model provides a framework for assessing the aging of transformer insulation using historical load characteristics and hot spot temperatures. Inspection data and other environmental calculations can be used together to calculate a relative health score for the transformer.

“Combine these insights with real-time assessments from smart devices and we can start to build a complete picture,” Brown said.

The most important effort we see, though, is getting control of your data.

In the end, utilities will have data from different sensors, different vendors and different sources. Whether it’s line sensors, transformer sensors or AMI data, it’s important to have a defined process to gather the data, ensure the quality of it and make it readily available for use.

The earlier a utility provider establishes this in their journey, the better positioned they will be to make smarter decisions and deliver higher reliability for their customers.

Unlocking the power of existing data

Steve brown, Kforce Principal Industry Solutions

“Having a standardized scoring system allows us to then look across the grid to determine the assets most in need of repair or replacement. This ensures our investment plans are aligned to deliver the best reliability for what are often scarce capital and operating and management budgets.”

a recent audit

American Society of Civil Engineers.

most recent annual report

Steve brown, Kforce Principal Industry Solutions

IEEE Annex PC57.91 G Model

Michigan Commission audit

Learn more

How to Optimize Your Professional Brand on LinkedIn

Stay Updated on Industry Trends with Twitter

How to Use Instagram During Your Job Search

Related articles

In conversations with distribution leaders, our Kforce Consulting Solutions teams often find companies get stuck on how to move forward in an environment of legacy and modern devices.

Utilities have a lot of real-time data on their newer devices but might only have inspection data on most of their legacy devices.

“We see them struggle to make sense of the disparate views of their assets,” Brown said. “In some cases, they aren’t even using the data from their newer assets because their processes are still oriented to their legacy assets.”

Leading companies are tapping into data from both their legacy and modern devices to build an integrated equipment health scoring system.

For example, the IEEE Annex PC57.91 G Model provides a framework for assessing the aging of transformer insulation using historical load characteristics and hot spot temperatures. Inspection data and other environmental calculations can be used together to calculate a relative health score for the transformer.

AI-powered reliability:

Applied AI in Banking: How 4 powerful use cases are driving growth