READ THE

FULL MAGAZINE

VIEW THE

PODCAST

Related Insights

World’s Most Admired Companies 2025:

5 Questions to

Answer to Grow

Your Business

How Mastercard’s Innovation Culture �Fuels Growth

READ THE

FULL MAGAZINE

VIEW THE

PODCAST

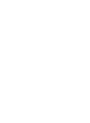

Denis Lates has been “almost there” for two decades. His mission centers on men’s shirts—but not just any shirts: He wants to create the perfect button-down. One that’s non-wrinkling, sweat wicking, odor resistant, and everlasting, with the right look for the moment. And when he’s not working on shirts, he’s working on men’s chinos and blazers and joggers. All with one goal: perfection.

His days involve staying ahead of street-fashion trends and developing innovative products by shopping, taking photos, purchasing samples, and globally sourcing fabrics. He travels to factories �to help ensure, in his words, “perfect outcomes.” In short, impeccable menswear has been the obsession of Lates’ life, to the point of taking on an existence of its own. “I’ve just immersed myself �in it, to where menswear is almost like a person,” he says. “That’s what drives me to look at something so intently.”

It’s a noble pursuit—one that, as it turns out, occurs in virtually every nook and cranny of the business world, in one form or another: the quest for design perfection. Yes, even in these tough, often brutal corporate times, dedicated inventors are quietly chasing their Holy Grail. Name a product—a medication, a type of food, anything—and some designer, scientist, or manager is out there trying to make it better. They may have the full backing of their boss or company, but even if they don’t, they’re not likely to stop pursuing their obsession.

Behind all their efforts lies a nagging question: Do today’s companies have an appetite for bankrolling intensive design processes? And should they? Indeed, firms are obviously facing enormous pressures from tariffs and massive market swings. Even without such looming events, firms producing “perfect” products can lose business if customers hold on to them too long. “It’s hard,” says Sara Beckman, a teaching professor at Berkeley’s Haas School of Business. “Designers face an uphill battle at most companies.” As a rule, she explains, companies are structured around launching products and tracking sales, not creating perfection. “Designing a product that customers will really covet is a different mindset,” she says.

Typical companies host long-term, medium-term, and short-term development portfolios. It’s the long term that can be a money pit, fraught with risk. No firm wants to be left holding the bag after �a decade of development. Indeed, be it the Edsel or the laser disc, corporate history books are full �of fiascos.

This isn’t to say that industries won’t still spend billions to achieve top performance—especially in aerospace and defense, where nearly a third of invested capital goes toward research and development. Pharmaceutical companies spend over 80 percent of invested capital on R&D, even if �just one out of every 5,000 new compounds is ultimately approved as a new medication. But today’s companies devote an average of just 8 percent of their capital to R&D, according to figures from the NYU Stern School of Business, and firms’ investments continue to decrease: Over the last five years, corporate R&D budgets have, on average, lagged behind inflation by 12 percent.

Almost every product can be improved, �forcing companies to decide whether to �fund the efforts.

The problem

The devotion to perfection can energize—�or bankrupt—firms.

why it matters

Take some risks and evaluate designers �based on customer-success metrics.

The solution

Sure, the solo designer working around the clock is a popular archetype, but it’s not necessarily the path to the greatest ideas. “Organizations know that they are insulated,” says Liz Gerber, professor of mechanical engineering at Northwestern University’s McCormick School of Engineering. “The best ideas often do not come from within.” Here’s why:

You’ve probably given minimal thought to the shirt you picked out this morning, unless it’s constricting or dripping with stains. Lates sees it differently. “It’s almost like looking at a piece of art,” he says. After more than two decades designing menswear for top retailers, he can’t not design. “It’s really tough when I look at friends. I start seeing ways to shape and make their attire look better.” Before vacations, he packs clothes for all of his family members (he calls it “packing everybody’s assortment”). In other words, his obsession with menswear is a lifestyle.

On the job, Lates asks four questions when considering a new garment: Is it timeless? Does it serve a purpose? Is it performing? Is it perfect? It’s that last question that can be paralyzing. To him, perfection means a shirt that is flawlessly doing what it needs to do, through a combination of perfect fabric and sharp design. In a form-fitting shirt, that might mean four-way stretch, so that the fabric allows movement in all directions; active stretch, for a sudden jog up a flight of stairs; and recovery stretch, to return it to its original shape. And that’s just the stretch.

He knows that most customers are blissfully unaware of his efforts. Typical purchasers know that they want, say, a no-wrinkle shirt with moisture-wicking fabric, but they don’t realize that it’s the box pleats down the back that allow their arms to move freely. “It’s those little things that probably don’t make it onto the website,” Lates says, “but are what we’re working on and trying to evolve.”

These days, Lates’s mind is occupied with fabric characteristics. He’s deep into the development of a cooling cotton for summer months, and a breathable cotton for activewear. He notes that these are gross simplifications of the variables his mind is crunching. “It’s not necessarily about the fabric performing, but about the garment performing,” he says. Is there mechanical stretch? Is there ventilation? Is it friggin’ perfect?

Collaborative Innovation 101

1: THE PERFECT BUTTON-DOWN

Designers devote entire careers to CREATiNG FLAWLESS PRODUCTS. With today’s pressures, can firms afford such noble pursuits?

PERFECTION

By Arianne Cohen / Illustrations by Tim Ames

Perfectionists’ �DRiVE FOR PERFECTiON often fuels their �diligence and work ethic—alongside �a lot of misery.

More ideas lead to better products.

“Ideas are not solitary—people�take attributes of multiple ideas and�combine them,” says Gerber.

Sharp ideas come from far away.�Customers in different cultures�look at the product through the�lens of a different set of values.

Good concepts come from customers.�Only a parent is going to suggest�clothes that grow, toys that self-sanitize,�and basketballs that are silent.

Innovations spring up simultaneously.�Typically, new approaches are in the�ether. The more people you talk to, the�more likely you are to discover one.

Haters have fantastic ideas.

The disgruntled neighbor of a�motorcycle owner is likely to have�valuable (albeit bitter!) input.

Private complaints are awesome.�Customers who feel involved�in development are less likely�to air complaints publicly.

It’s hard to be a designer who wants to create a perfect product in corporate America. A series of extreme challenges awaits. First there’s the customer. All designers must manage the yawning gap between expert knowledge and user comprehension. And customers do dumb things, unfortunately. For example, it’s completely normal for a shopper to buy a rechargeable toothbrush that a company has poured millions into, drain the battery one day, overcharge it the next, then use it to clean shower grout. You see the rub.�

Then there’s the problem of funding. A key US tax credit (aptly called the Credit for Increasing Research Activities) encourages research spending, but R&D productivity—a measure of how efficiently those efforts are converted into valuable outputs—has been in decline since the 1980s. That’s partly because most executive pay is tied to financial management. “To this day, firms still don’t know what the right amount of R&D spending is,” says Anne Marie Knott, a professor of business at the Olin School of Business at Washington University. A so-called “short-termism” reigns that prioritizes immediate results over long-term innovation and forces designers to work on often-brutal corporate deadlines. “They’re kind of racing against the clock,” says Knott.�

Even if corporations cooperated more, another detail can gum up the works: the mindsets of perfectionists, who typically don’t feel good about themselves, experts say, unless they achieve excellence. “It’s almost a substitute for their self-esteem,” says Thomas Curran, associate professor �of psychology at the London School of Economics, and author of The Perfection Trap: Embracing �the Power of Good Enough. Perfectionists’ drive for perfection often fuels their diligence and work ethic—alongside a lot of misery, procrastination, and indecisiveness. For some, it becomes an unsustainable path, compounded by corporate pressures to reach perfection faster and cheaper, �that can ultimately land them in therapy.

In short, the odds are fairly harrowing. Yet it’s somewhat clear that there will always be designers who won’t give up. Through obsessive attention to detail and a will that has no boundaries, this group of obsessives believes that perfection can still triumph in the corporate world, in good times or bad. And their dreams can run the gamut from the perfect button-down to the niftiest digital writing tablet to the sturdiest dishwasher, or even a better cosmetics package.

It’s hard.

DESiGNERS FACE �AN UPHiLL BATTLE

at most

companies.”

“

THE PERFECT BUTTON-DOWN

I’ve just �iMMERSED MYSELF

in it, to where �menswear is almost �like a person.

“

Denis Lates �(Design Director, Mizzen+Main)

Fraillon’s design expertise sits at the center of a Venn diagram where packaging imperatives meet sustainability. The process begins when a cosmetic company comes to his sustainable-packaging company to pitch an idea, be it well-defined (a concept for a container for a cosmetics product) or very loose. Perhaps the client wants a pump bottle for a new lotion. This is where Fraillon draws on his engineering prowess: A very thick lotion formulation will not flow upward through a pump. He suggests alternatives; both sides collaborate. This back-and-forth can take a week, or a year. Often, wonderfully sustainable packaging might interfere with the chemistry of the product. “We can’t always do exactly what we want. We need solutions that do more with less,” he says.

If you’re envisioning Fraillon spending his days leaning over molds of bottle shapes, you’re partly right, though you should also envision him sending emails—many, many emails to coordinate those balanced solutions, in the right shapes, for clients and factories. Avoiding nonrecyclable plastic requires efforts, because manufacturers have long been spoiled by it. “Plastic can do anything,” he says. Ideally, packaging will be both recyclable and made of recycled materials, with a minimal carbon footprint, which requires eliminating or reducing new plastic in favor of glass, aluminum, or other options, like a recyclable resin. Until recently, nearly all cosmetics companies prized some degree of sustainability, though the calculation has changed in recent months. “Pricing has become paramount,” Fraillon says.

His resume is a Who’s Who of iconic cosmetics companies: Estée Lauder, Smashbox, Bare Escentuals, Coty, Avon, Victoria’s Secret Beauty. Now that he finally co-runs his own shop, he says, he can curate a warehouse of many thousands of packages from partner factories, allowing him to pull dozens of examples of, say, a round bottle with a round cap. He frequently pokes his head into a nearby Sephora—he can’t help himself. “It’s just to see how our packages are doing in the wild.”

THE PERFECT COSMETIC PACKAGING

Jerome Fraillon �(CEO, Alder Packaging)

We can’t

ALWAYS DO

EXACTLY what

we want.

“

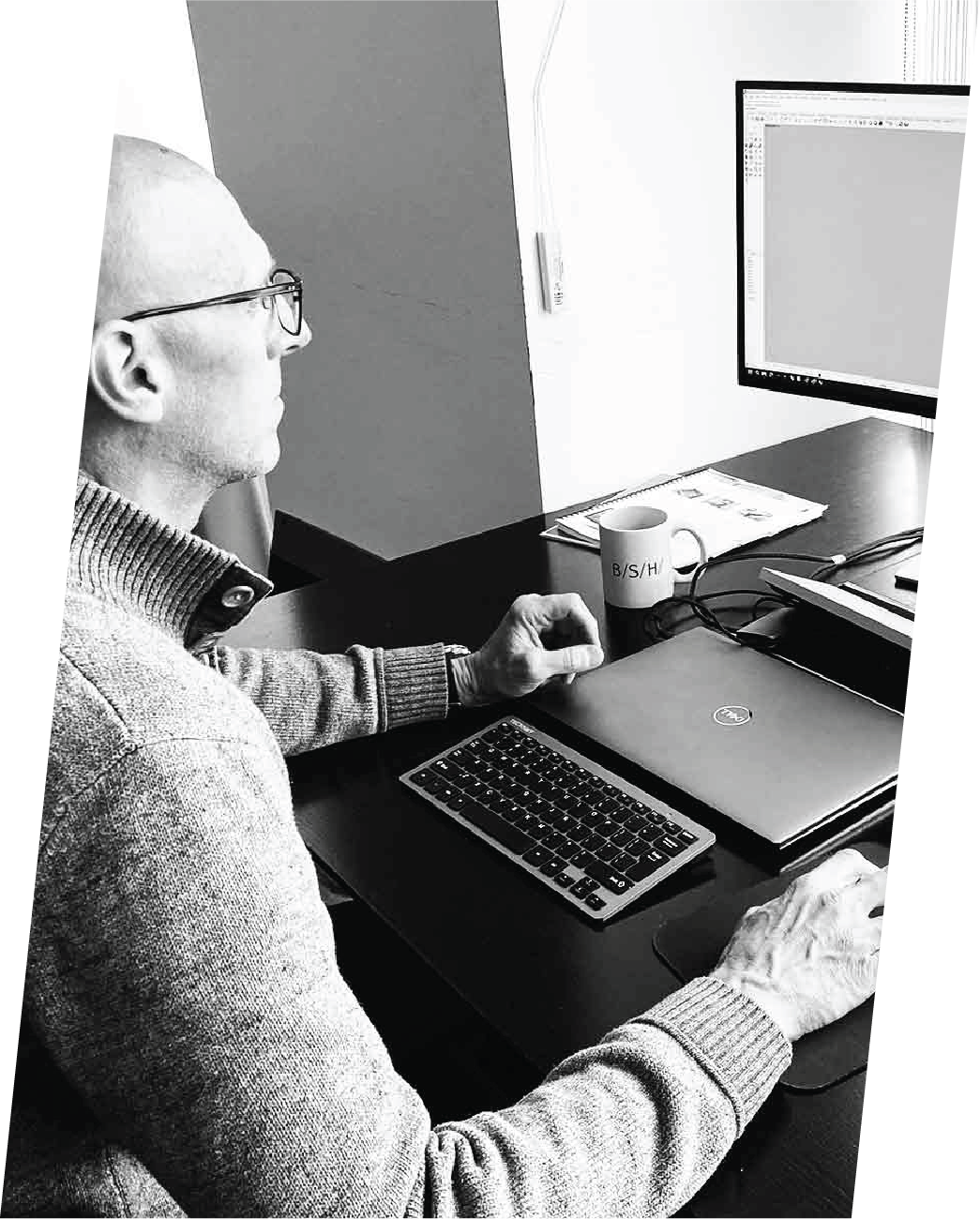

Clark didn’t think corporate America was calling his name. After high school, he spent a decade working with his hands—in restaurants, landscaping companies, and factories in Louisville, Kentucky. Then he met an industrial engineer who suggested he explore product design. Clark visited the program at the University of Cincinnati. “There were no books! People were in shops building and drawing cool stuff.” He knew it then: “This is for me!” He would eventually graduate third in his class.

Today, his mandate is dishwashers—specifically, making Bosch-branded dishwashers more enjoyable for consumers. As he sees it, the dishwasher is the star of the kitchen at the end of the night, long after the fridge and oven have done their jobs. “Dishwashing is the most disliked task in the kitchen, so making it easier, user-friendly, and faster is key,” he says.

This goal is complicated by the fact that dishwasher users do very weird things with their tableware. Bosch’s research arm regularly invites customers to pick out dishes similar to their own, then load a dishwasher—while researchers watch through one-way glass. Some customers are extremely organized, carefully slotting items into the dish rack like they’re playing Tetris. For others, “there’s chaos,” Clark says. Customers, it turns out, don’t appreciate detailed instructions. They’ll accept a few icons printed on the racks as hints, but that’s it. They prefer not to have to pay any more attention than that. So the question Clark’s team asks is, “Did everything get cleaned?” The answer needs to be “Absolutely.”

Clark will poke his head into the local Lowe’s and Home Depot and nonchalantly listen to buyers’ conversations. “When I hear consumers say, ‘Hey, this thing is awesome and makes my life better,’ that’s my passion and what keeps me going.”

THE PERFECT DISHWASHER

Jason Clark �(Senior Industrial Designer, BSH Home Appliances Corp.)

When I hear consumers say,

‘HEY, THiS THiNG

iS AWESOME…’

that’s my passion

and what keeps

me going.

“

Solberg is obsessed with a single goal: a digital tablet for PDFs and books that will recreate the feeling of writing by hand on paper. That’s it—no email, messaging, or other bells and whistles that might distract. “Writing has two and a half millennia of development, iterations, and optimization. It’s kind of naïve to disregard that,” he says.

But what kind of pen? And what kind of paper? The feeling of writing, it turns out, encompasses physical experiences like friction (between pen and paper), paper feel (against the hand), and flex (of both pen and paper). His team in Oslo compiled what they called the Bank, a gathering of “every pen, pencil, writing tool, and type of paper that you can imagine.” First, staffers tested various analog writing combinations, in increasingly large groups. Then came the hat trick: to break down those physical experiences into components, then recreate each one in digital form by imprinting the paper-surface features onto tablet glass, then molding plastic styluses that look like pencil tips under a microscope.

This, of course, resulted in the opposite of a final product: Solberg had many (many) prototypes on his hands. Which was the best? Enter the company’s Wine Tasting Club. The name is a misnomer: They test mostly digital tablets, sometimes while sipping a beverage, and log their personal likes and dislikes. “A lot of this is super subjective,” says Solberg. “You won’t find one writing experience that’s perfect for everyone.”

But if recreating writing in digital form seems like an outsize goal, Solberg has an even bigger one in mind: to facilitate people’s best thinking. This has been a lifelong pursuit, dating back to when he says he built “basically the first iPhone” in his living room as a tween, using the innards of a Macintosh computer. He is turned off by the limitations of constantly dinging software on laptops and smartphones, but intrigued by the idea of pen and paper as a way of thinking. His litmus test for whether to pursue a feature to keep his dream of perfection alive is, “Does this help people think better?

THE PERFECT ELECTRIC WRITING TOOL

Mats Herding Solberg �(Head of Product Incubation, reMarkable)

Does this

help people

think better?

“

2: THE PERFECT COSMETIC PACKAGING >

3: THE PERFECT DISHWASHER >

4: THE PERFECT ELECTRIC WRITING TOOL >

4: THE PERFECT ELECTRIC WRITING TOOL >

3: THE PERFECT DISHWASHER >

2: THE PERFECT COSMETIC PACKAGING >

4: THE PERFECT ELECTRIC WRITING TOOL >

4: THE PERFECT ELECTRIC WRITING TOOL >

3: THE PERFECT DISHWASHER >

3: THE PERFECT DISHWASHER >

1: THE PERFECT BUTTON-DOWN >

1: THE PERFECT BUTTON-DOWN >

2: THE PERFECT COSMETIC PACKAGING

4: THE PERFECT ELECTRIC WRITING TOOL >

4: THE PERFECT ELECTRIC WRITING TOOL >

1: THE PERFECT BUTTON-DOWN >

1: THE PERFECT BUTTON-DOWN >

2: THE PERFECT COSMETIC PACKAGING >

2: THE PERFECT COSMETIC PACKAGING >

3: THE PERFECT DISHWASHER

2: THE PERFECT COSMETIC PACKAGING >

2: THE PERFECT COSMETIC PACKAGING >

1: THE PERFECT BUTTON-DOWN >

1: THE PERFECT BUTTON-DOWN >

3: THE PERFECT DISHWASHER >

3: THE PERFECT DISHWASHER >

4: THE PERFECT ELECTRIC WRITING TOOL

Designers devote entire careers to CREATiNG FLAWLESS PRODUCTS. With today’s pressures, can firms afford such noble pursuits?

PERFECTION

Sure, the solo designer working around the clock is a popular archetype, but it’s not necessarily the path to the greatest ideas. “Organizations know that they are insulated,” says Liz Gerber, professor of mechanical engineering at Northwestern University’s McCormick School of Engineering. “The best ideas often do not come from within.” Here’s why:

Collaborative Innovation 101

Denis Lates has been “almost there” for two decades. His mission centers on men’s shirts—but not just any shirts: He wants to create the perfect button-down. One that’s non-wrinkling, sweat wicking, odor resistant, and everlasting, with the right look for the moment. And when he’s not working on shirts, he’s working on men’s chinos and blazers and joggers. All with one goal: perfection.

His days involve staying ahead of street-fashion trends and developing innovative products by shopping, taking photos, purchasing samples, and globally sourcing fabrics. He travels to factories �to help ensure, in his words, “perfect outcomes.” In short, impeccable menswear has been the obsession of Lates’ life, to the point of taking on an existence of its own. “I’ve just immersed myself �in it, to where menswear is almost like a person,” he says. “That’s what drives me to look at something so intently.”

It’s a noble pursuit—one that, as it turns out, occurs in virtually every nook and cranny of the business world, in one form or another: the quest for design perfection. Yes, even in these tough, often brutal corporate times, dedicated inventors are quietly chasing their Holy Grail. Name a product—a medication, a type of food, anything—and some designer, scientist, or manager is out there trying to make it better. They may have the full backing of their boss or company, but even if they don’t, they’re not likely to stop pursuing their obsession.

Behind all their efforts lies a nagging question: Do today’s companies have an appetite for bankrolling intensive design processes? And should they? Indeed, firms are obviously facing enormous pressures from tariffs and massive market swings. Even without such looming events, firms producing “perfect” products can lose business if customers hold on to them too long. “It’s hard,” says Sara Beckman, a teaching professor at Berkeley’s Haas School of Business. “Designers face an uphill battle at most companies.” As a rule, she explains, companies are structured around launching products and tracking sales, not creating perfection. “Designing a product that customers will really covet is a different mindset,” she says.

Typical companies host long-term, medium-term, and short-term development portfolios. It’s the long term that can be a money pit, fraught with risk. No firm wants to be left holding the bag after �a decade of development. Indeed, be it the Edsel or the laser disc, corporate history books are full �of fiascos.

This isn’t to say that industries won’t still spend billions to achieve top performance—especially in aerospace and defense, where nearly a third of invested capital goes toward research and development. Pharmaceutical companies spend over 80 percent of invested capital on R&D, even if �just one out of every 5,000 new compounds is ultimately approved as a new medication. But today’s companies devote an average of just 8 percent of their capital to R&D, according to figures from the NYU Stern School of Business, and firms’ investments continue to decrease: Over the last five years, corporate R&D budgets have, on average, lagged behind inflation by 12 percent.

Almost every product can be improved, �forcing companies to decide whether to �fund the efforts.

The problem

The devotion to perfection can energize—�or bankrupt—firms.

why it matters

Take some risks and evaluate designers �based on customer-success metrics.

The solution

You’ve probably given minimal thought to the shirt you picked out this morning, unless it’s constricting or dripping with stains. Lates sees it differently. “It’s almost like looking at a piece of art,” he says. After more than two decades designing menswear for top retailers, he can’t not design. “It’s really tough when I look at friends. I start seeing ways to shape and make their attire look better.” Before vacations, he packs clothes for all of his family members (he calls it “packing everybody’s assortment”). In other words, his obsession with menswear is a lifestyle.

On the job, Lates asks four questions when considering a new garment: Is it timeless? Does it serve a purpose? Is it performing? Is it perfect? It’s that last question that can be paralyzing. To him, perfection means a shirt that is flawlessly doing what it needs to do, through a combination of perfect fabric and sharp design. In a form-fitting shirt, that might mean four-way stretch, so that the fabric allows movement in all directions; active stretch, for a sudden jog up a flight of stairs; and recovery stretch, to return it to its original shape. And that’s just the stretch.

He knows that most customers are blissfully unaware of his efforts. Typical purchasers know that they want, say, a no-wrinkle shirt with moisture-wicking fabric, but they don’t realize that it’s the box pleats down the back that allow their arms to move freely. “It’s those little things that probably don’t make it onto the website,” Lates says, “but are what we’re working on and trying to evolve.”

These days, Lates’s mind is occupied with fabric characteristics. He’s deep into the development of a cooling cotton for summer months, and a breathable cotton for activewear. He notes that these are gross simplifications of the variables his mind is crunching. “It’s not necessarily about the fabric performing, but about the garment performing,” he says. Is there mechanical stretch? Is there ventilation? Is it friggin’ perfect?

Denis Lates has been “almost there” for two decades. His mission centers on men’s shirts—but not just any shirts: He wants to create the perfect button-down. One that’s non-wrinkling, sweat wicking, odor resistant, and everlasting, with the right look for the moment. And when he’s not working on shirts, he’s working on men’s chinos and blazers and joggers. All with one goal: perfection.

His days involve staying ahead of street-fashion trends and developing innovative products by shopping, taking photos, purchasing samples, and globally sourcing fabrics. He travels to factories to help ensure, in his words, “perfect outcomes.” �In short, impeccable menswear has been the obsession of Lates’ life, to the point of taking on an existence of its own. “I’ve just immersed myself in it, to where menswear is almost like a person,” he says. “That’s what drives me to look at something so intently.”

It’s a noble pursuit—one that, as it turns out, occurs in �virtually every nook and cranny of the business world, in one form or another: the quest for design perfection. Yes, even in these tough, often brutal corporate times, dedicated inventors are quietly chasing their Holy Grail. Name a product—a medication, a type of food, anything—and some designer, scientist, or manager is out there trying to make it better. They may have the full backing of their boss or company, but even if they don’t, they’re not likely to stop pursuing their obsession.

Behind all their efforts lies a nagging question: Do today’s companies have an appetite for bankrolling intensive design processes? And should they? Indeed, firms are obviously facing enormous pressures from tariffs and massive market swings. Even without such looming events, firms producing “perfect” products can lose business if customers hold on to them too long. “It’s hard,” says Sara Beckman, a teaching professor at Berkeley’s Haas School of Business. “Designers face an uphill battle at most companies.” As a rule, she explains, companies are structured around launching products and tracking sales, not creating perfection. “Designing a product that customers will really covet is a different mind-set,” she says.

Typical companies host long-term, medium-term, and short-term development portfolios. It’s the long term that can be a money pit, fraught with risk. No firm wants to be left holding the bag after a decade of development. Indeed, be it the Edsel or the laser disc, corporate history books are full of fiascos.

This isn’t to say that industries won’t still spend billions to achieve top performance—especially in aerospace and defense, where nearly a third of invested capital goes toward research and development. Pharmaceutical companies spend over 80 percent of invested capital on R&D, even if just one out of every 5,000 new compounds is ultimately approved as a new medication. But today’s companies devote an average of just 8 percent of their capital to R&D, according to figures from the NYU Stern School of Business, and firms’ investments continue to decrease: Over the last five years, corporate �R&D budgets have, on average, lagged behind inflation by �12 percent.

You’ve probably given minimal thought to the shirt you picked out this morning, unless it’s constricting or dripping with stains. Lates sees it differently. “It’s almost like looking at a piece of art,” he says. After more than two decades designing menswear for top retailers, he can’t not design. “It’s really tough

when I look at friends. I start seeing ways to shape and make their attire look better.” Before vacations, he packs clothes for all of his family members (he

calls it “packing everybody’s assortment”). In other words, his obsession with menswear is a lifestyle.

On the job, Lates asks four questions when considering a new garment: Is it timeless? Does it serve a purpose? Is it performing? Is it perfect? It’s that last question that can be paralyzing. To him, perfection means a shirt that is flawlessly doing what it needs to do, through a combination of perfect fabric

and sharp design. In a form-fitting shirt, that might mean four-way stretch, so that the fabric allows movement in all directions; active stretch, for a sudden

jog up a flight of stairs; and recovery stretch, to return it to its original shape. And that’s just the stretch.

He knows that most customers are blissfully unaware of his efforts. Typical purchasers know that they want, say, a no-wrinkle shirt with moisture-wicking fabric, but they don’t realize that it’s the box pleats down the back that allow their arms to move freely. “It’s those little things that probably don’t make it onto the website,” Lates says, “but are what we’re working on and trying to evolve.”

These days, Lates’s mind is occupied with fabric characteristics. He’s deep into the development of a cooling cotton for summer months, and a breathable cotton for activewear. He notes that these are gross simplifications of the variables his mind is crunching. “It’s not necessarily about the fabric performing, but about the garment performing,” he says. Is there mechanical stretch? Is there ventilation? Is it friggin’ perfect?

1: THE PERFECT BUTTON-DOWN

Denis Lates �(Design Director, Mizzen+Main)

I’ve just �iMMERSED MYSELF

in it, to where �menswear is almost �like a person.

You’ve probably given minimal thought to the shirt you picked out this morning, unless it’s constricting or dripping with stains. Lates sees it differently. “It’s almost like looking at a piece of art,” he says. After more than two decades designing menswear for top retailers, he can’t not design. “It’s really tough

when I look at friends. I start seeing ways to shape and make their attire look better.” Before vacations, he packs clothes for all of his family members (he

calls it “packing everybody’s assortment”). In other words, his obsession with menswear is a lifestyle.

On the job, Lates asks four questions when considering a new garment: Is it timeless? Does it serve a purpose? Is it performing? Is it perfect? It’s that last question that can be paralyzing. To him, perfection means a shirt that is flawlessly doing what it needs to do, through a combination of perfect fabric

and sharp design. In a form-fitting shirt, that might mean four-way stretch, so that the fabric allows movement in all directions; active stretch, for a sudden

jog up a flight of stairs; and recovery stretch, to return it to its original shape. And that’s just the stretch.

He knows that most customers are blissfully unaware of his efforts. Typical purchasers know that they want, say, a no-wrinkle shirt with moisture-wicking fabric, but they don’t realize that it’s the box pleats down the back that allow their arms to move freely. “It’s those little things that probably don’t make it onto the website,” Lates says, “but are what we’re working on and trying to evolve.”

These days, Lates’s mind is occupied with fabric characteristics. He’s deep into the development of a cooling cotton for summer months, and a breathable cotton for activewear. He notes that these are gross simplifications of the variables his mind is crunching. “It’s not necessarily about the fabric performing, but about the garment performing,” he says. Is there mechanical stretch? Is there ventilation? Is it friggin’ perfect?

1: THE PERFECT BUTTON-DOWN

Denis Lates �(Design Director, Mizzen+Main)

I’ve just �iMMERSED MYSELF

in it, to where �menswear is almost �like a person.

Clark didn’t think corporate America was calling his name. After high school, he spent a decade working with his hands—in restaurants, landscaping companies, and factories in Louisville, Kentucky. Then he met an industrial engineer who suggested he explore product design. Clark visited the program at the University of Cincinnati. “There were no books! People were in shops building and drawing cool stuff.” He knew it then: “This is for me!” He would eventually graduate third in his class.

Today, his mandate is dishwashers—specifically, making Bosch-branded dishwashers more enjoyable for consumers. As he sees it, the dishwasher is the star of the kitchen at the end of the night, long after the fridge and oven have done their jobs. “Dishwashing is the most disliked task in the kitchen, so making it easier, user-friendly, and faster is key,” he says.

This goal is complicated by the fact that dishwasher users do very weird things with their tableware. Bosch’s research arm regularly invites customers to pick out dishes similar to their own, then load a dishwasher—while researchers watch through one-way glass. Some customers are extremely organized, carefully slotting items into the dish rack like they’re playing Tetris. For others, “there’s chaos,” Clark says. Customers, it turns out, don’t appreciate detailed instructions. They’ll accept a few icons printed on the racks as hints, but that’s it. They prefer not to have to pay any more attention than that. So the question Clark’s team asks is, “Did everything get cleaned?” The answer needs to be “Absolutely.”

Clark will poke his head into the local Lowe’s and Home Depot and nonchalantly listen to buyers’ conversations. “When I hear consumers say, ‘Hey, this thing is awesome and makes my life better,’ that’s my passion and what keeps me going.”

3: THE PERFECT DISHWASHER

Jason Clark �(Senior Industrial Designer, BSH Home Appliances Corp.)

“

“

“

“

“

>

<

“

“

“

“

“

“

“

>

<

>

<

>

<

World’s Most Admired Companies 2025:

5 Questions to

Answer to Grow

Your Business

How Mastercard’s Innovation Culture �Fuels Growth

NEXT: THE PERFECT COSMETIC PACKAGING >

NEXT: THE PERFECT DISHWASHER >

NEXT: THE PERFECT ELECTRIC WRITING TOOL >

NEXT: THE PERFECT BUTTON-DOWN >

5 Questions to

Answer to Grow

Your Business

World’s Most Admired Companies 2025: