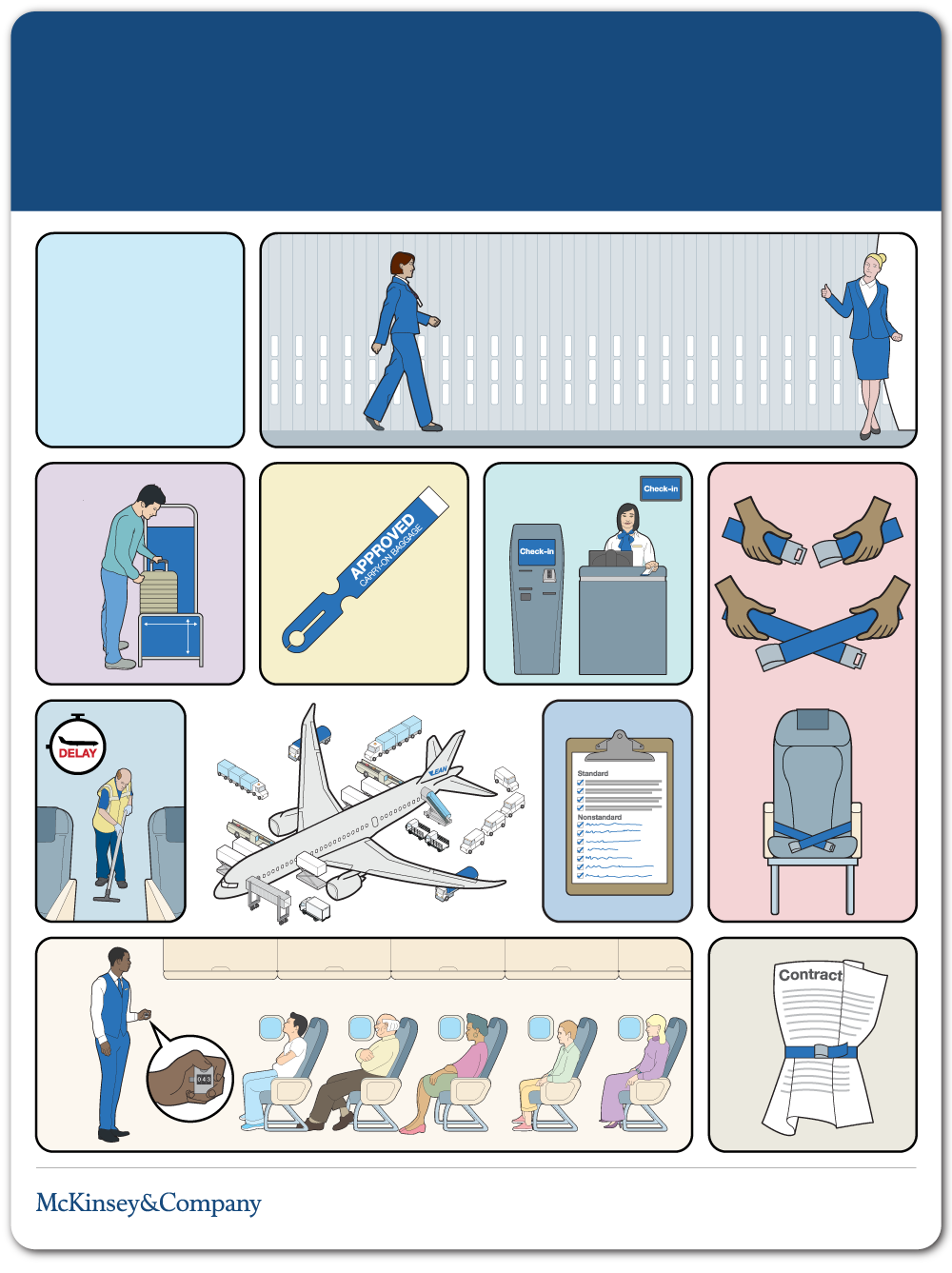

A ten-point checklist for leaders

Lean airlines

Click on each illustration to find out more

Don’t: Fail to make lean improvements a part

of every contract with suppliers

Squeezing a supplier’s margins goes only so far. Lean airlines seek tangible ways to remove waste throughout their end-to-end processes—including

those of suppliers.

Don’t: Have flight attendants count passengers

In a world of very high load factors, truly lean airlines no longer count passengers. Getting past a gate agent in

a single-file queue without having your boarding pass scanned is a magician’s trick.

Don’t: Keep your list of routine maintenance items static

Lean systems aim to

eliminate surprises and make processes less variable. The list of routine maintenance items should be updated continually through experience and data.

Don’t: Make the gate the

only place where aircraft

can be cleaned, catered,

and serviced

Lean airlines control downtime for scarce assets, such as the gate. If you have aircraft at remote pads, you can service them there.

Don’t: Use the same aircraft-turnaround process for on-time and delayed flights

Would passengers want to wait an extra ten minutes for

a perfectly clean plane in the event of delays? The leanest airlines have a normal turnaround and a “power” turn for delayed flights.

Don’t: Have your cleaning crews cross or buckle

seat belts

Cabins where belts are lined up across the seats look neat, but even a middling airline will

spend serious money on this routine, and only the first people boarding behold that neatness. If you must fiddle with the seat belts, lay them out unbuckled and parallel to the armrests.

Don’t: Take check-in for granted

Check-in adds no value for customers. Some airlines sensibly assume that the predicted manifest is correct, deleting no-shows and

adding go-shows just before departure.

Don’t: Have your check-in agents put “approved” tags on carry-ons

Placing these tags is a classic case of overproduction: a process that adds no value and that no customer would pay for. The lean way is to address the fundamental issue (bag length) and to control it at the point of universal access (boarding).

Don’t: Use the “box” to size carry-on bags

The carry-on-sizing box is hard to use and prone to

false positives. A better,

leaner solution? A line, marked on the boarding-queue poles, that indicates a carry-on’s acceptable length (or rather height, since bags stand on their wheels).

Don’t: Have agents walk down the jet bridge to confirm that aircraft are ready to board

In a truly lean airline, boarding starts at departure minus a

fixed number of minutes, unless someone says otherwise. Flight crew or cleaners shouldn’t determine the process’s cycle time.

A ten-point checklist for leaders

Lean airlines

Click on each illustration to find out more