KEY DATES

About the Award

Judging Criteria

Tips for Entries

ABOUT THE INNOVATION IN BIOPLASTICS AWARD

The Innovation in Bioplastics Award, presented by the PLASTICS Bioplastics Division, will recognize one outstanding innovation in unique and creative applications of bioplastics materials, products, or manufacturing processes by a company. The 2025 award winner will be recognized during the Bioplastics Week social media campaign during the week of October 20 – 26.

This award, along with our other 5 Sustainability Innovation Awards, will be presented at a future PLASTICS event.

INNOVATION

Innovation is the act of being creative, introducing something new, and representing a progression of the state-of-the-art. For this measure, the judges will ask - does the bioplastic material, product, or manufacturing process truly bring something unique and groundbreaking to the marketplace? Examples may include:

Use of new materials never before used in processes or products

Unusual combinations of materials in a process or product

Use of new material in a current product

Early applications of new process technology

First use of a particular process to produce a particular part

New performance features of a product

Pioneering applications into new markets

TIPS FOR ENTRIES

While there is no maximum word count, try to strike a balance between providing sufficient information and brevity. Consider that this application will be read by volunteer judges alongside multiple others and the information may be used in the press release or on social media.

Provide sufficient information about your material, product, or manufacturing process to explain how it is relevant to the bioplastics industry. For example, new or novel biobased polymers might include what type of feedstock it is made from.

Include challenges you’ve overcome or that you’re still working through. Part of the innovation process is trial and error, which adds important context to your story!

Include product photos, links to marketing brochures, and/or technical documentation. In the case of claims related to a form of biodegradability (industrial/home compostable, marine/soil biodegradable, or anaerobically digestible), technical information has been appreciated by the judges.

ABOUT THE AWARDS

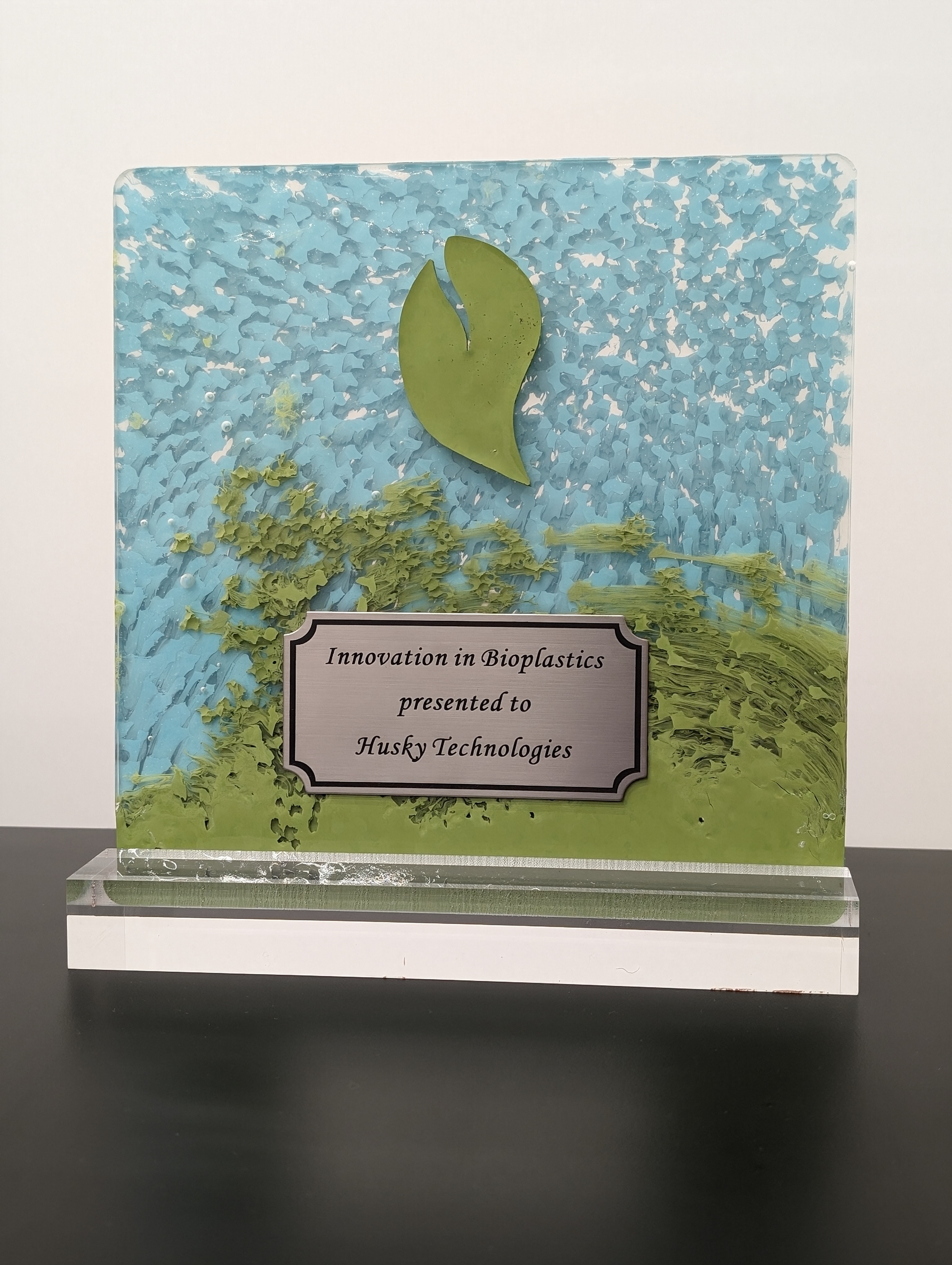

The award plaque embodies the essence of this awards program, which is bioplastic sustainability and innovation. The most recent award plaques were manufactured by Plastic Forming Enterprises (PFE) and made with PLA, provided by NatureWorks. The design allowed for PFE to try out a new process, which ended up being a success! PLASTICS truly appreciates both Plastics Forming Enterprises and NatureWorks for their contribution in helping these awards come to life.

June 12, 2026

Nomination period opens

August 21, 2026

Nomination period closes

August 24, 2026

Judging process begins

Week of September 14, 2026

Winner is notified

October 2026

Winner is announced

TBA

Winner is presented at a future PLASTICS sustainability event

Judging Criteria

About the Award

JUDGING CRITERIA

This competition is open to any corporation, partnership, or other business entity located within or outside of the United States that is not excluded by the Official Rules. The same company may submit multiple entries for different materials, products, or manufacturing processes, provided that a separate and complete entry from is submitted for each innovation. All applicants will be judged based on the three categories of Innovation, Environmental Impact, and Market Impact.

ENVIRONMENTAL IMPACT

Impact on the environment is a crucial consideration for any innovative venture. The Plastics Industry Association is committed to sustainable development and is supportive of those that are making strides to reach similar goals. For this criterion, judges will assess whether the bioplastic material, product, or manufacturing process provides some measure of enhanced sustainability? Examples may include:

A new material, product, or process that leads to improvements in waste reduction or efficient resource use

A process that consumes less water or energy compared to a traditional process

A product that results in pollution reduction or reduction in CO2 emissions

A finished product that is designed for circularity (recycling and/or composting)

MARKET IMPACT

A successful innovation is one that is able to scale up in or disrupt the current market. Even if your innovation is in the beginning stages of increasing scale, express your vision for what impact it is intended to have. The judges will be considering if the material, product, or manufacturing process currently or will likely soon have a significant impact on the marketplace. Questions to consider may include:

What is the potential impact to the marketplace?

Is the impact significant? If so, how?

Does the material, product, or process address a new market, or does it enhance the current market?

Tips for Entries

2025 – CJ Biomaterials for their Floreon Therma-Tech PLA-based compound, Press Release

2024 – Floreon Technologies Ltd. for their Floreon Therma-Tech PLA-based compound, Press Release

2023 – Husky Technologies for their UltraMelt™ Hot Runner System, Press Release

2022 – Anellotech for the first 100% bioPET bottle, Press Release

2021 – Eastman for their Aventa™ Renew cellulose-based resins, Press Release

2020 - Danimer Scientific & WinCup’s First commercially sold straws made of PHA, Press Release

2019 - Novamont for Mater-Bi, Press Release

2018 – Danimer Scientific & PepsiCo Industrial Compostable Snack Bag, Press Release

2017 – DuPont & ADM’s biobased furan dicarboxylic methyl ester (FDME)

2016 – Club Coffee’s PurPod100™, Press Release

2015 – Eastman Kodak’s bio-toner

2014 – Teknor Apex’s Terraloy® PLA compounds

2013 – Avantium’s development of polyethylene furanoate (PEF)

PAST AWARD WINNERS

Congratulations to our most recent Innovation in Bioplastics Award Winner, CJ Biomaterials!

CJ Biomaterials has created PHACT™ A1000P, an amorphous polyhydroxyalkanoate (aPHA). PHACT is a new and unique molecule with a soft, rubbery texture at room temperature, offering a flexibility and toughness that differs from existing performance characteristics in other PHAs. This makes it suitable for a wide range of applications—including flexible and rigid packaging, as well as foodservice ware, like take-out containers and utensils. It also acts as a high-performance modifier for PLA, significantly expanding PLA’s usability in various applications.

All questions can be emailed to Heather Nortz, Manager, Sustainability & Materials.

Questions?

View the Official Rules of the Award Program

Sign Up to Be Notified