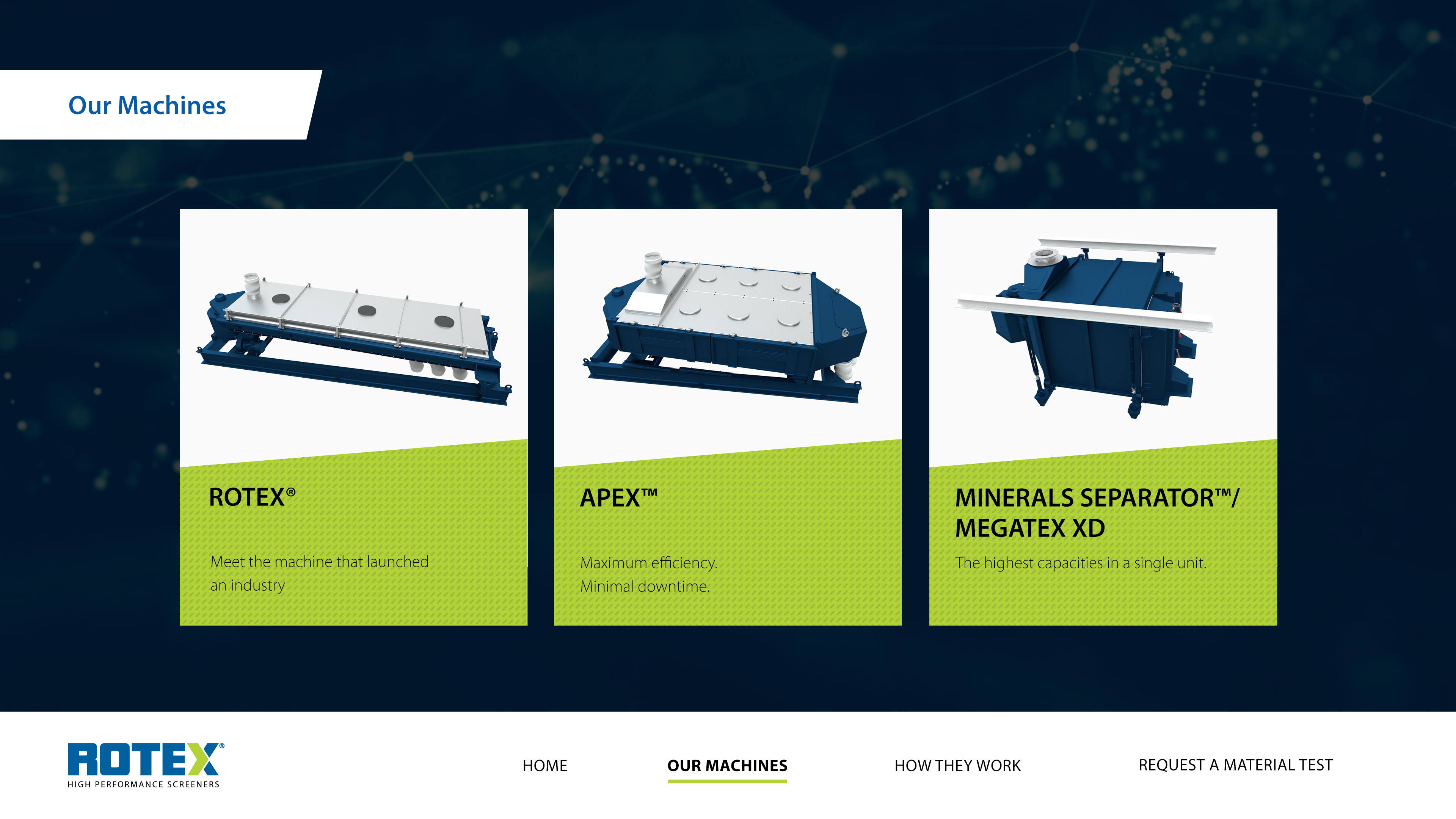

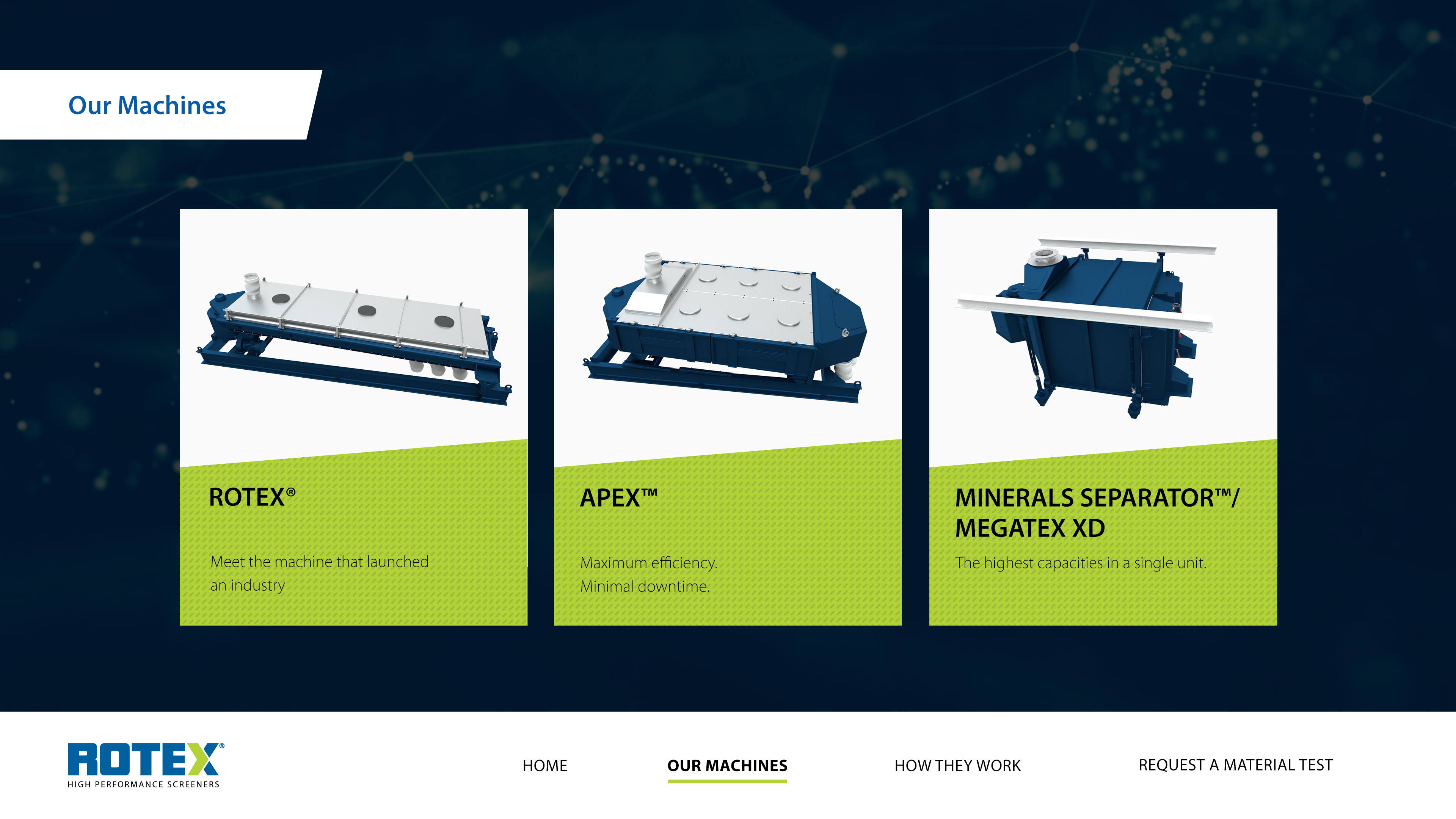

Our Machines

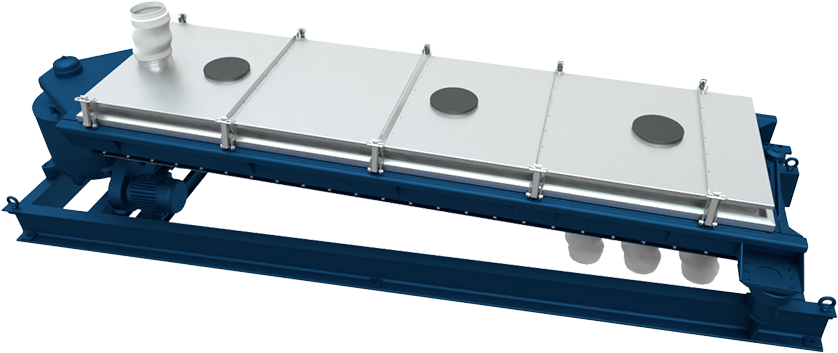

ROTEX®

Meet the machine that launched an industry

APEX™

Maximum efficiency. Minimal downtime.

Minerals Separator™/ MEGATEX XD

The highest capacities in a single unit.

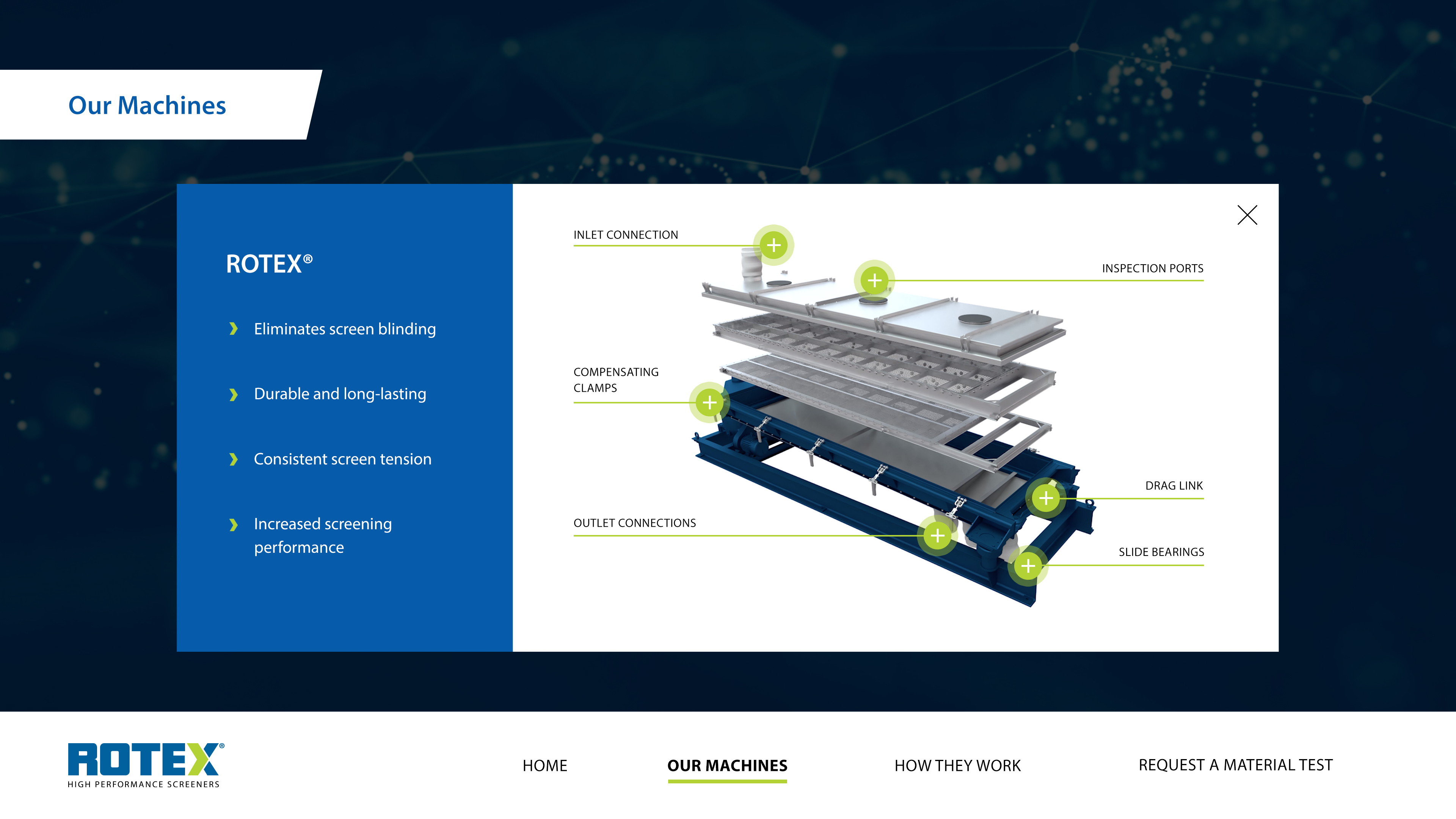

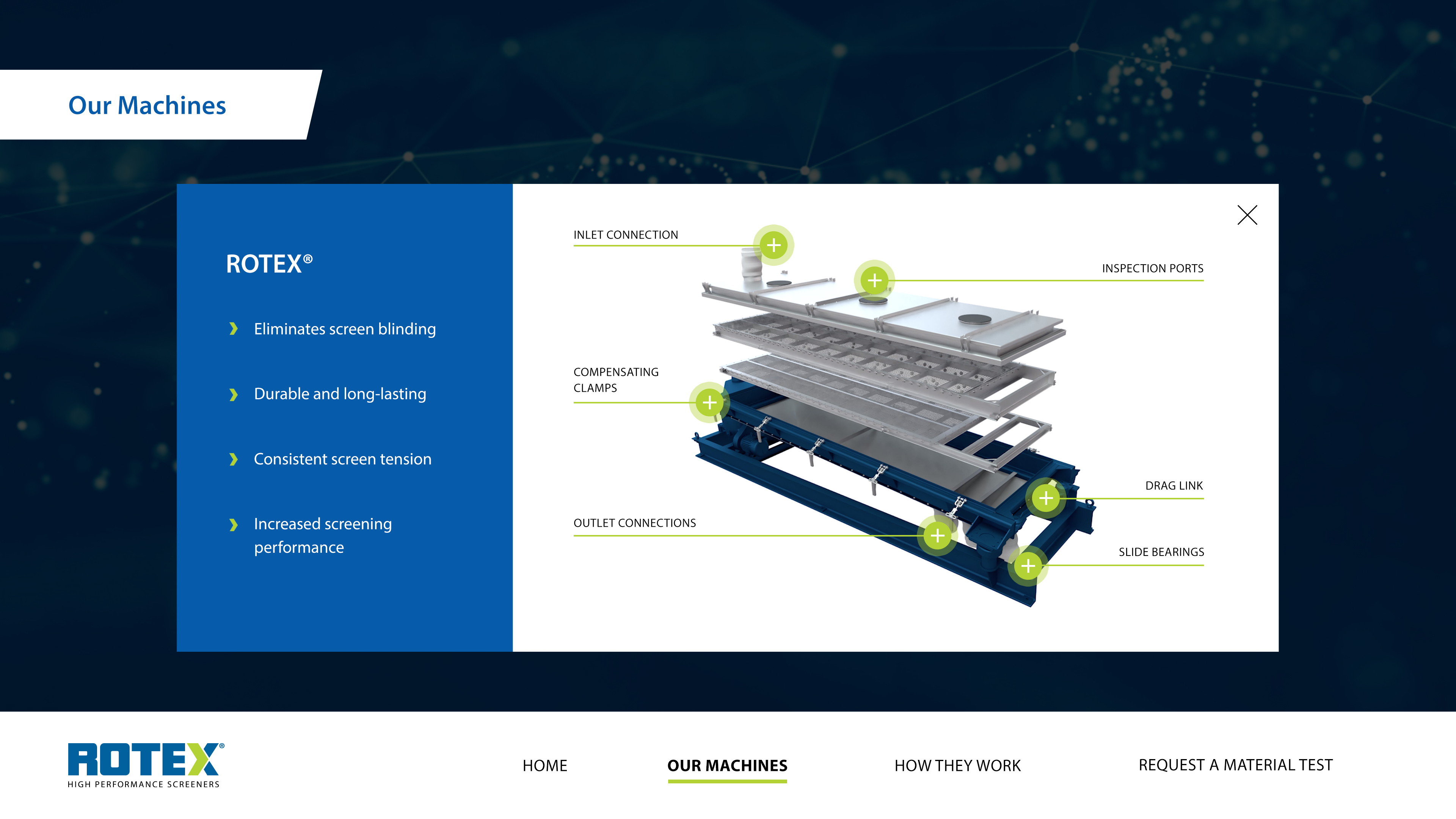

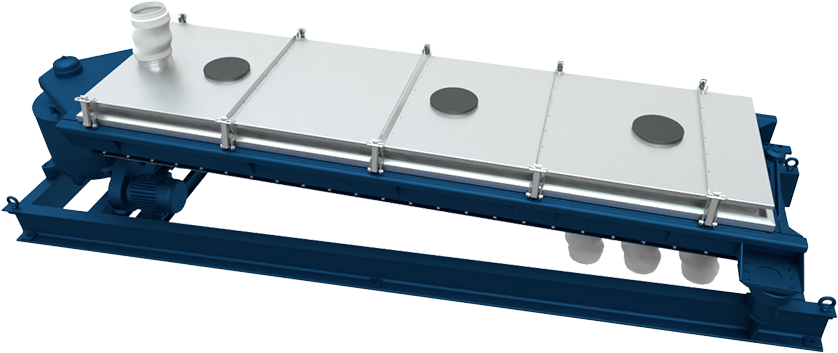

ROTEX®

Eliminates screen blinding

Durable and long-lasting

Consistent screen tension

Increased screening performance

INLET CONNECTION

COMPENSATING CLAMPS

OUTLET CONNECTIONS

INSPECTION PORTS

DRAG LINK

SLIDE BEARINGS

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

COMPENSATING CLAMPS

Patented adjustable clamps ensure uniform sealing of cover and screen decks. The screens are attached using Rotex tensioning clips, which automatically draw the correct tension on the screen clothing.

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

Inspection ports

When the machine is stopped, you can easily remove the inspection cap and ensure the screener is operating correctly. This could include inspections for screen blinding, screen tears or material buildup.

Drag link

The drag link converts the gyratory motion created by the drive head to reciprocating motion for precise, near-size separation.

Slide Bearings

Only sliding friction is generated with our slide bearings, ensuring they are lightweight and have a long operating life while introducing minimal vibrations or noise.

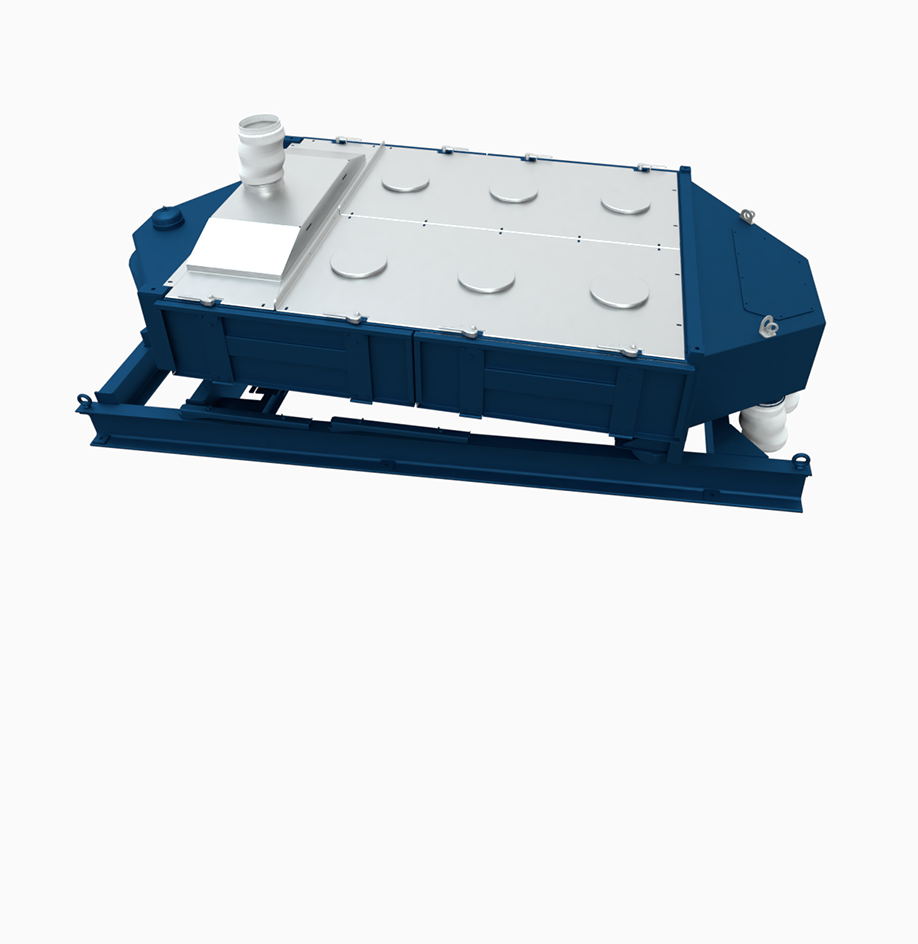

APEX™

Ergonomic design

Quick screen changes

Increased screening performance

Customizable

More uptime, more profit

Durable and long-lasting

INLET CONNECTION

DRIVE HEAD

SCREEN ACCESS

DOORS

INSPECTION PORTS

DISCHARGE CHUTE

DRAG LINK

OUTLET CONNECTIONS

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

DRIVE HEAD

Rotex drive heads come in three configurations.

• Single Weight Drive: Used on smaller machines

• Dynamic Absorber Drive

• Gear Drive

Screen Access Doors

Side access doors combined with pre-tensioned screen panels allow a single operator to change the entire machine in minutes.

Inspection ports

When the machine is stopped, you can easily remove the inspection cap and ensure the screener is operating correctly. This could include inspections for screen blinding, screen tears or material buildup.

Discharge chute

Customize the discharge chute by adding hinges to improve accessibility for product cleanouts and inspections.

Drag link

The drag link converts the gyratory motion created by the drive head to reciprocating motion for precise, near-size separation.

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

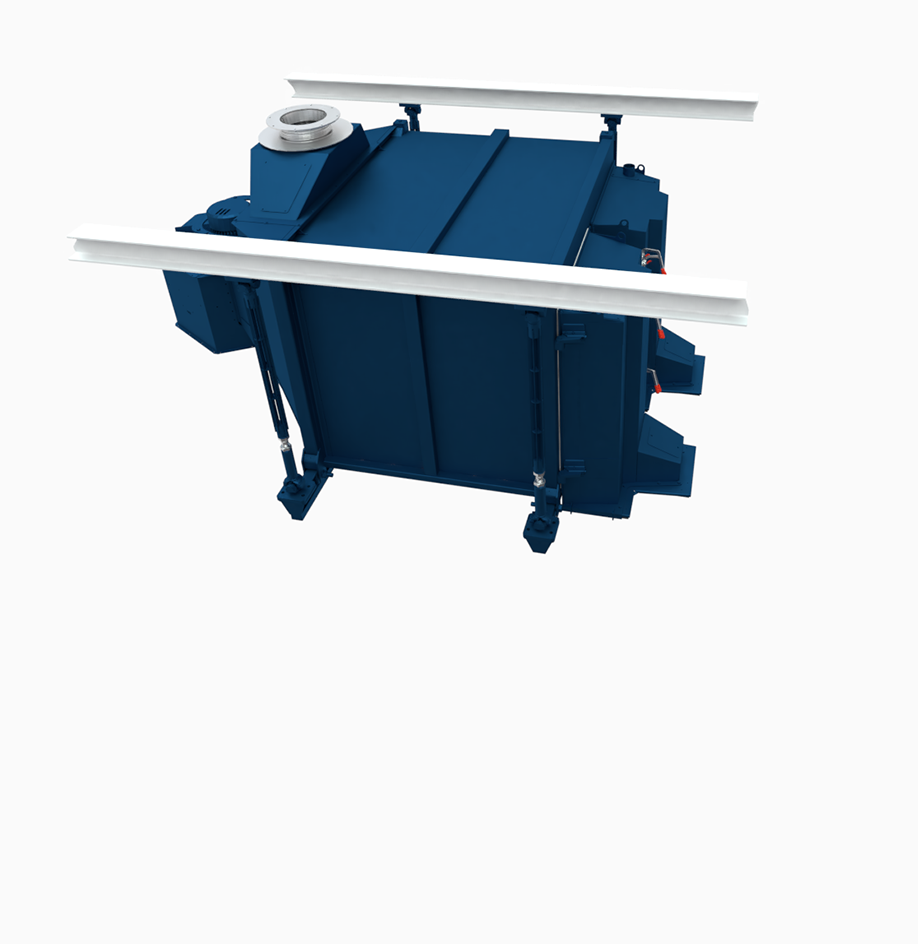

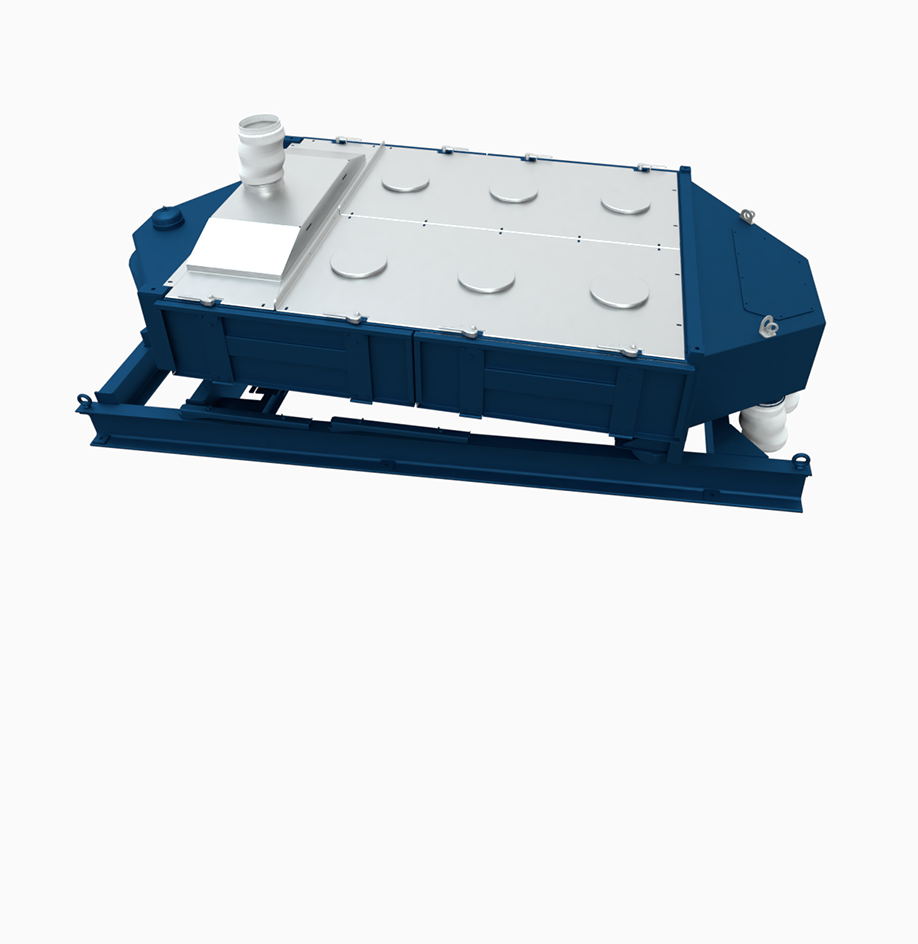

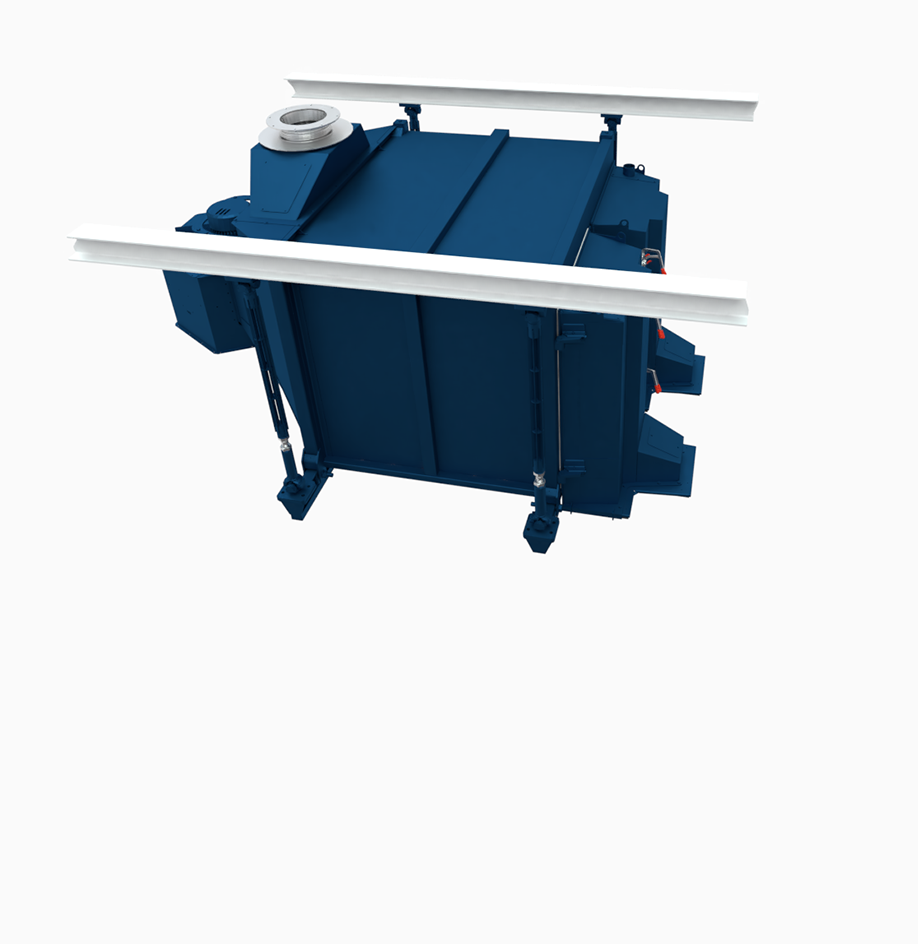

Minerals Separator™/ MEGATEX XD

Reduced downtime

No product leakage

Durable and long-lasting

Consistent screen tension

Independent screen access

SLIDING INLET

DRIVE

UNIVERSAL JOINTS

EASY ACCESS DOORS

BRUSH DISCHARGE

Sliding inlet

The sliding inlet eliminates the hassle associated with flexible connections. Say good-bye to torn flexible connections, and improve plant safety. A Teflon™ wear ring and close running flange to allow for movement of the machine.

DRIVE

A simple reactionary drive cartridge incorporating two spherical roller bearings provides years of longevity.

Universal joints

Universal joints accommodate the torsional forces created by the unique Rotex Gyratory Reciprocating Motion while bearing the entire weight of the machine. In addition, 500 to 1,000 pounds of abrasion-resistant liners ensure your machine will withstand any application.

EASY ACCESS DOORS

Customized heavy-duty DESTACO door clamps allow quick and easy screen access.

BRUSH DISCHARGE

Using brush discharge connections eliminates the challenges caused by flexible outlet connections, including reducing dust, containing separated product fractions, and increasing the life of the machine by up to 10x.

HOME

OUR MACHINES

HOW THEY WORK

REQUEST A MATERIAL TEST

HOME

OUR MACHINES

HOW THEY WORK

REQUEST A MATERIAL TEST

Our Machines

ROTEX®

Meet the machine that launched an industry

APEX™

Maximum efficiency. Minimal downtime.

Minerals Separator™/ MEGATEX XD

The highest capacities in a single unit.

ROTEX®

Eliminates screen blinding

Durable and long-lasting

Consistent screen tension

Increased screening performance

INLET CONNECTION

COMPENSATING CLAMPS

OUTLET CONNECTIONS

INSPECTION PORTS

DRAG LINK

SLIDE BEARINGS

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

COMPENSATING CLAMPS

Patented adjustable clamps ensure uniform sealing of cover and screen decks. The screens are attached using Rotex tensioning clips, which automatically draw the correct tension on the screen clothing.

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

Inspection ports

When the machine is stopped, you can easily remove the inspection cap and ensure the screener is operating correctly. This could include inspections for screen blinding, screen tears or material buildup.

Drag link

The drag link converts the gyratory motion created by the drive head to reciprocating motion for precise, near-size separation.

Slide Bearings

Only sliding friction is generated with our slide bearings, ensuring they are lightweight and have a long operating life while introducing minimal vibrations or noise.

APEX™

Ergonomic design

Quick screen changes

Increased screening performance

Customizable

More uptime, more profit

Durable and long-lasting

INLET CONNECTION

DRIVE HEAD

SCREEN ACCESS

DOORS

INSPECTION PORTS

DISCHARGE CHUTE

DRAG LINK

OUTLET CONNECTIONS

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

DRIVE HEAD

Rotex drive heads come

in three configurations.

• Single Weight Drive:

Used on smaller machines

• Dynamic Absorber Drive

• Gear Drive

Screen Access Doors

Side access doors combined with pre-tensioned screen panels allow a single operator to change the entire machine in minutes.

Inspection ports

When the machine is stopped, you can easily remove the inspection cap and ensure the screener is operating correctly. This could include inspections for screen blinding, screen tears or material buildup.

Discharge chute

Customize the discharge chute by adding hinges to improve accessibility for product cleanouts and inspections.

Drag link

The drag link converts the gyratory motion created by the drive head to reciprocating motion for precise, near-size separation.

Outlet and inlet connection

Rotex customizes each machine configuration to match the exact application needs. Connection options range from rubber to sanitary BFM connections to nutating connections. Ask your rep which is right for you.

Minerals Separator™/ MEGATEX XD

Reduced downtime

No product leakage

Durable and long-lasting

Consistent screen tension

Independent screen access

SLIDING INLET

DRIVE

UNIVERSAL JOINTS

EASY ACCESS DOORS

BRUSH DISCHARGE

Sliding inlet

The sliding inlet eliminates the hassle associated with flexible connections. Say good-bye to torn flexible connections, and improve plant safety. A Teflon™ wear ring and close running flange to allow for movement of the machine.

DRIVE

A simple reactionary drive cartridge incorporating two spherical roller bearings provides years of longevity.

Universal joints

Universal joints accommodate the torsional forces created by the unique Rotex Gyratory Reciprocating Motion while bearing the entire weight of the machine. In addition, 500 to 1,000 pounds of abrasion-resistant liners ensure your machine will withstand any application.

EASY ACCESS DOORS

Customized heavy-duty DESTACO door clamps allow quick and easy screen access.

BRUSH DISCHARGE

Using brush discharge connections eliminates the challenges caused by flexible outlet connections, including reducing dust, containing separated product fractions, and increasing the life of the machine by up to 10x.

HOME

OUR MACHINES

HOW THEY WORK

REQUEST A MATERIAL TEST