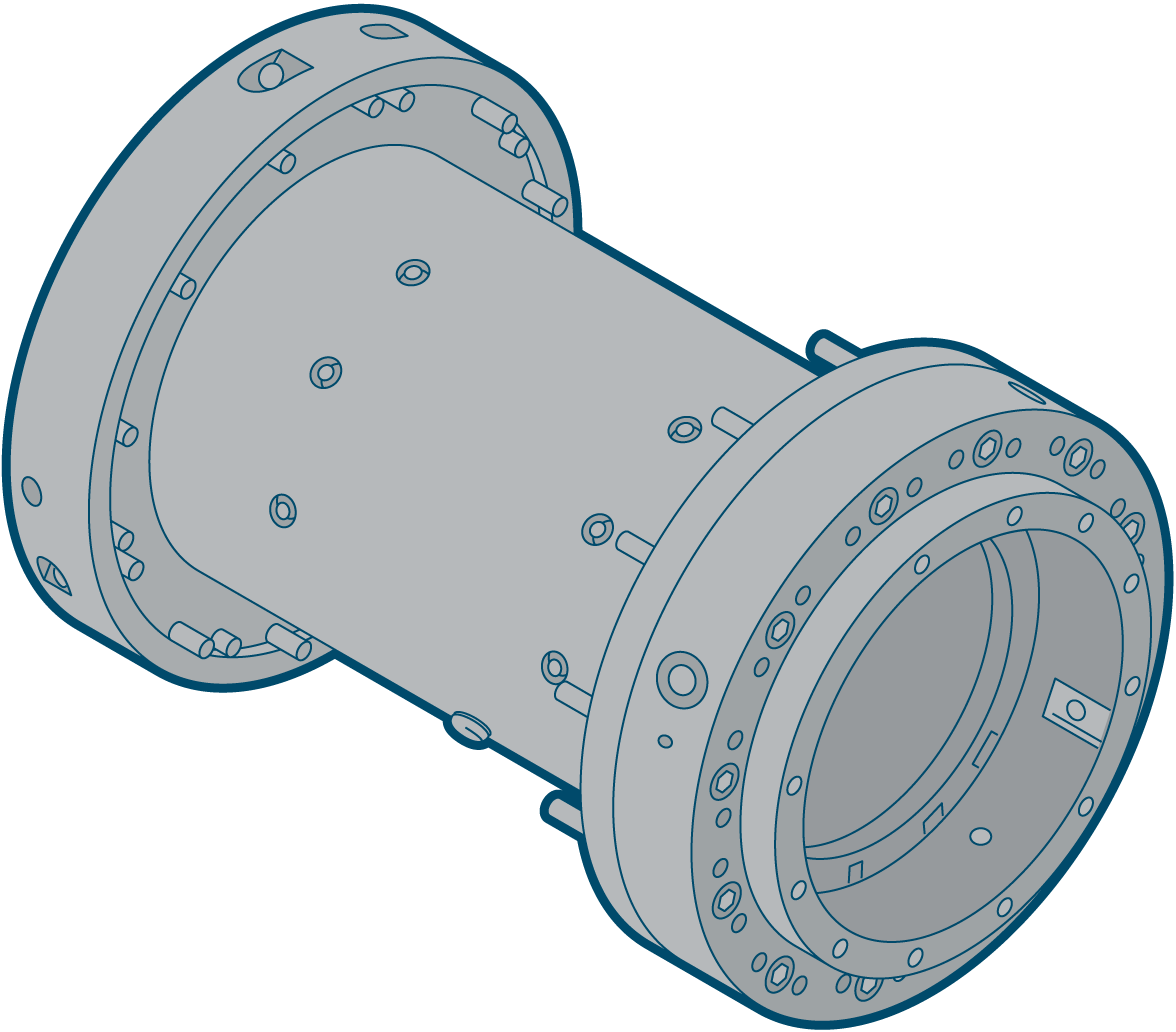

EvoTube®

A simplified stern tube system that consitutes a new standard.

Available for oil and water lube systems.

Can be modified from one system to another.

Stern tube significantly reduced in length.

Forward sten tube bearing replaced with inboard intermediate line shaft bearing.

Significant reduction of lubricant required in the system.

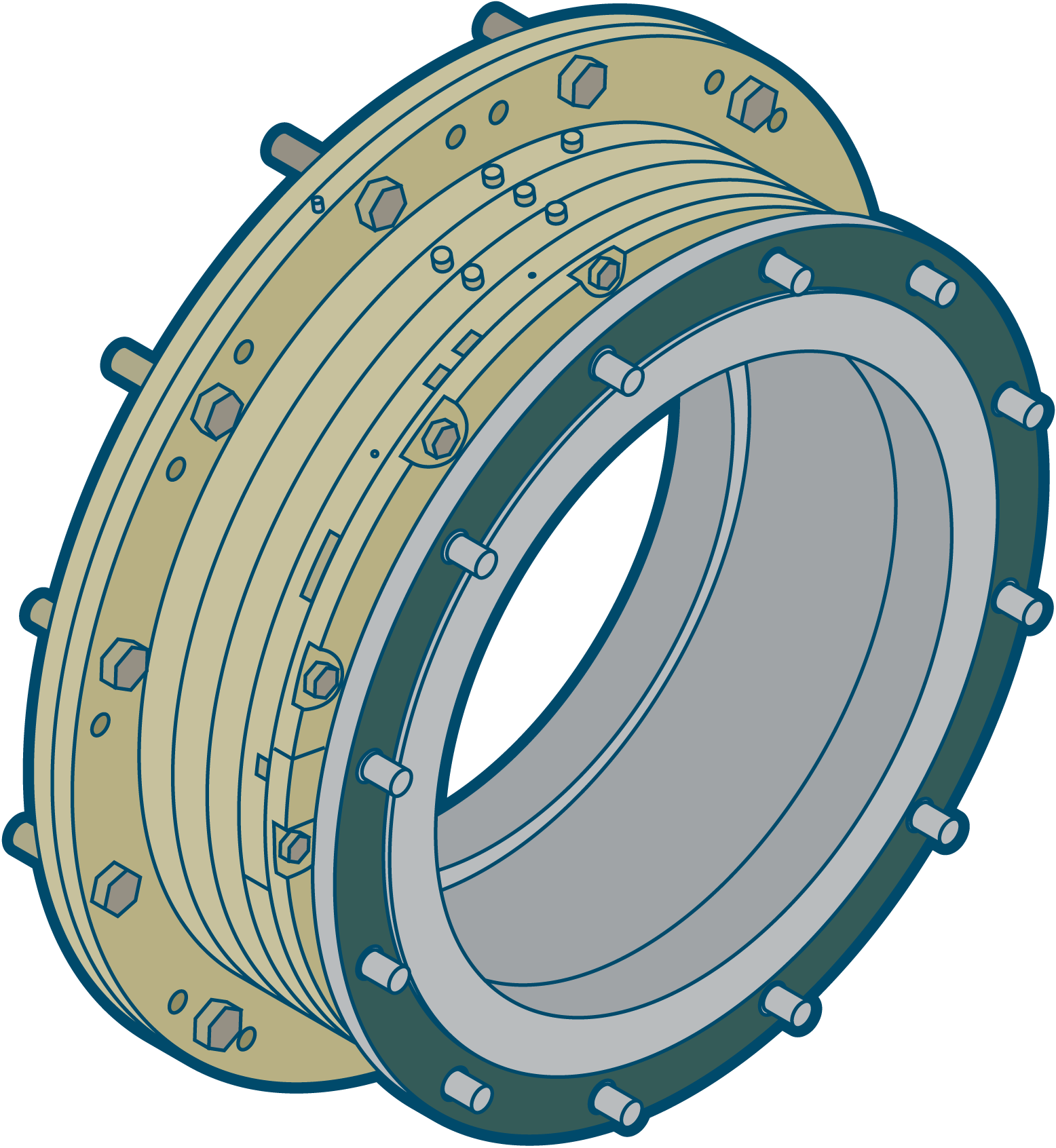

10-Years Airguard Seal

The first air-type seal with a 10-year service interval

Builds on proven Wärtsilä Airguard performance. Fit it and operate.

Long service interval means greater vessel availability.

Increased vessel availability leads to significant cost savings.

IntelliSafe®

Reduce risk with a stern tube bearing that monitors and protects itself

Self-regulating bearing ensures there is always sufficient lubricating oil film.

More robust against unfavourable operating conditions.

Eliminates the presence of metal-to-metal contact leading to a significantly extended lifecycle.

Shaft Line Monitoring

A shaft line that monitors itself and offers advanced warning of potential issues.

Captures the overall relationship of the key components in the shaft line.

Offers a full view on its condition by validation of its performance.

Performance can be validated and reviewed.

Shaft loading conditions are monitored.

Alerts for deviation from standard operating conditions and out-of-range conditions.

Lifecycle consultancy for preventative maintenance and operating cost savings.

Monitor the effects of low-speed condition, manoeuvring and actual data compared to nominal design values at installation.

Meet the future of shaft line solutions

Our new offering brings together some of our latest and most innovative solutions for the maritime industry. By improving the efficiency, performance and availability of your vessel, these technologies reduce your costs while increasing your profitability.

Shaft Line Monitoring

A shaft line that monitors itself and offers advanced warning of potential issues.

Captures the overall relationship of the key components in the shaft line.

Offers a full view on its condition by validation of its performance.

Performance can be validated and reviewed.

Shaft loading conditions are monitored.

Alerts for deviation from standard operating conditions and out-of-range conditions.

Lifecycle consultancy for preventative maintenance and operating cost savings.

Monitor the effects of low-speed condition, manoeuvring and actual data compared to nominal design values at installation.

Hover to find out more