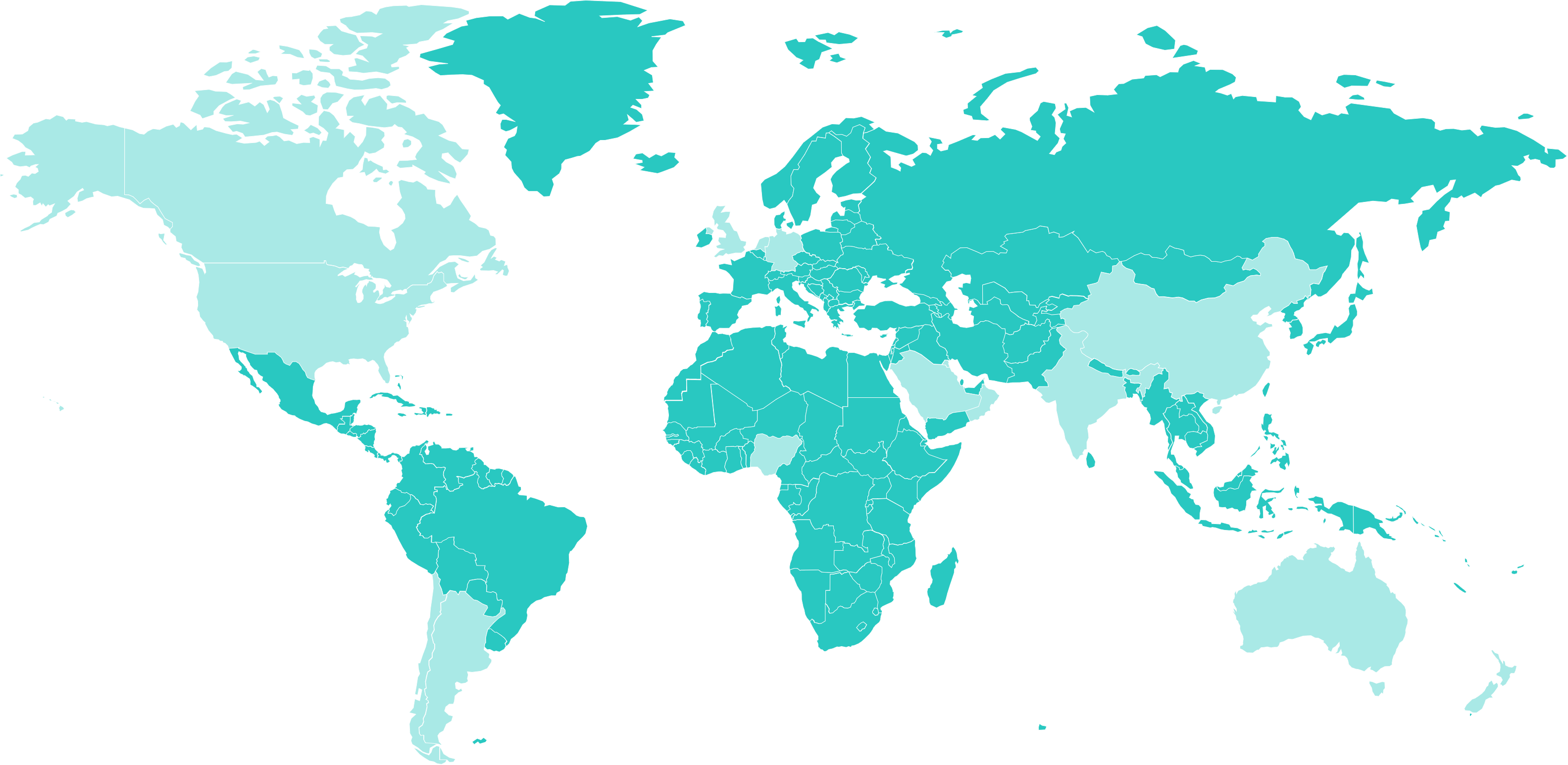

Saudi Arabia

Our team in Saudi Arabia used the SEAL Sustainable Design framework to design wellhead platforms powered by photovoltaic solar system. This approach provided cost and schedule benefits by reducing the subsea cable installation scope. The recommendation has reduced CO2 equivalent by 16,000 tonnes and reduced environmental risks for the project.

Australia

Our team in Australia applied the SEAL Safety in Design framework to a minerals processing plant project involving hazardous process acid. They combined our systems to implement SID, developing a comprehensive hazard register and collaborating with global experts and specialist vendors to come up with innovative safety measures. This has reduced process hazards to operators through effective use of hierarchy of controls.

New Zealand

Our team in New Zealand incorporated the SEAL Safety in Design framework on a dairy processing plant. A thorough review using qualitative risk analysis, dispersion modelling, Hazard Identification workshops, and Layers of Protection Analysis workshop identified hazards and mitigation measures for the plant. This resulted in implementation of active safety measures to reduce residual process hazards.

India

Our team in India implemented the SEAL Safety in Design framework on a mineral processing project, with a strong focus on mitigating hazards in a corrosive environment. The team systematically applied the SEAL framework to identify corrosion hazards and implement mitigation measures to enhance the plant's design features.

China

Our team in China implemented the SEAL Sustainable Design framework by standardizing the design of vacuum units, resulting in a reduction in the number of required units. This approach lowered capital costs, enhanced operational and maintenance flexibility, and reduced the facility's CO2 footprint.

Oman

Our team in Oman implemented the SEAL Sustainable Design framework to debottleneck a local facility and accommodate additional gas from a nearby field. We incorporated multiple solutions such as flared gas capture. This resulted in approximately 190,000 tonnes of CO2 being abated.

United Kingdom

Our team in the United Kingdom utilized the SEAL Sustainable Design framework to optimize and increase production capacity at two hydrocarbon processing sites. During the design phase, value creation ideas focused on reducing carbon emissions and saving water, leading to design measures such as re-sizing equipment and repurposing existing structures. These measures resulted in significant reductions in CO2 emissions and water savings.

Canada

Our team in Canada utilized the SEAL Safety in Design framework to assist with challenges in plant layout congestion and identification of safe escape routes. We used a 3D modelling tool to map out these escape routes, ensuring the plant layout included safe evacuation paths for personnel. This design incorporated the input from all relevant stakeholders to ensure it's fit for purpose.

USA

Our team in the United States incorporated the SEAL Sustainable Design framework on a refinery project to come up with ideas to reduce CO2 emissions. We approached the project with the customer as one team, which enhanced the creation of ideas to improve the project outcome. This resulted in a significant number of ideas being implemented with cost and sustainability benefits for the project.

Qatar

Our team in Qatar incorporated the SEAL Sustainable Design framework by prioritizing waste reduction and optimizing design solutions. This resulted in a significant reduction of CO2 emissions.

Nigeria

Our team in Nigeria implemented the SEAL Sustainable Design framework to eliminate continuous flaring at the local gas plant. We developed a SEAL plan to ensure strict implementation throughout the project, with strong collaboration with the customer’s project team to align on objectives. This resulted in a robust design that not only eliminates continuous flaring, but also meets the customer's goal of minimizing capital costs.

Germany

Our team in Germany applied the SEAL Safety in Design and Sustainable Design framework to enhance the existing design of a steam system in an Olefin unit. The new design captures the steam which was previously discharged to the atmosphere to improve the safety and sustainability of the Olefin unit.

The Netherlands

Our team in the Netherlands used the SEAL framework to conduct an alignment session with the customer, gaining a clear understanding of their safety and sustainability objectives. The SEAL alignment workshop showcased how SEAL could help address the customer's challenges while aligning the project objectives with their overall safety and sustainability goals.

Chile

Our team in Chile developed a SEAL app to digitalize the implementation of SEAL on projects. The SEAL app has been successfully piloted and planned for global adoption to provide further insights and visualizations.

Argentina

Our team in Argentina conducted a SEAL alignment session to understand the customer's HSE culture, sustainability goals and technical governance objectives. The team implemented the SEAL framework throughout project execution resulting in more than �30 innovative ideas which reduced costs and improved environmental performance.

Oman

Our team in Oman implemented the SEAL Sustainable Design framework to debottleneck a local facility and accommodate additional gas from a nearby field. We incorporated multiple solutions such as flared gas capture. This resulted in approximately 190,000 tonnes of CO2 being abated.